The primary raw material used to manufacture PTFE spacers is Polytetrafluoroethylene, a high-performance fluoropolymer most people know by the DuPont brand name Teflon. This material is chosen for its unique combination of properties, including exceptional chemical resistance, an extremely low coefficient of friction, and the ability to withstand a vast range of temperatures. These characteristics make PTFE spacers highly effective and durable in demanding industrial and mechanical applications.

The decision to use PTFE for a spacer is not about a single feature, but about its powerful combination of properties. Its chemical inertness, thermal stability, and self-lubricating surface create a high-performance component that solves problems where most other materials would quickly degrade or fail.

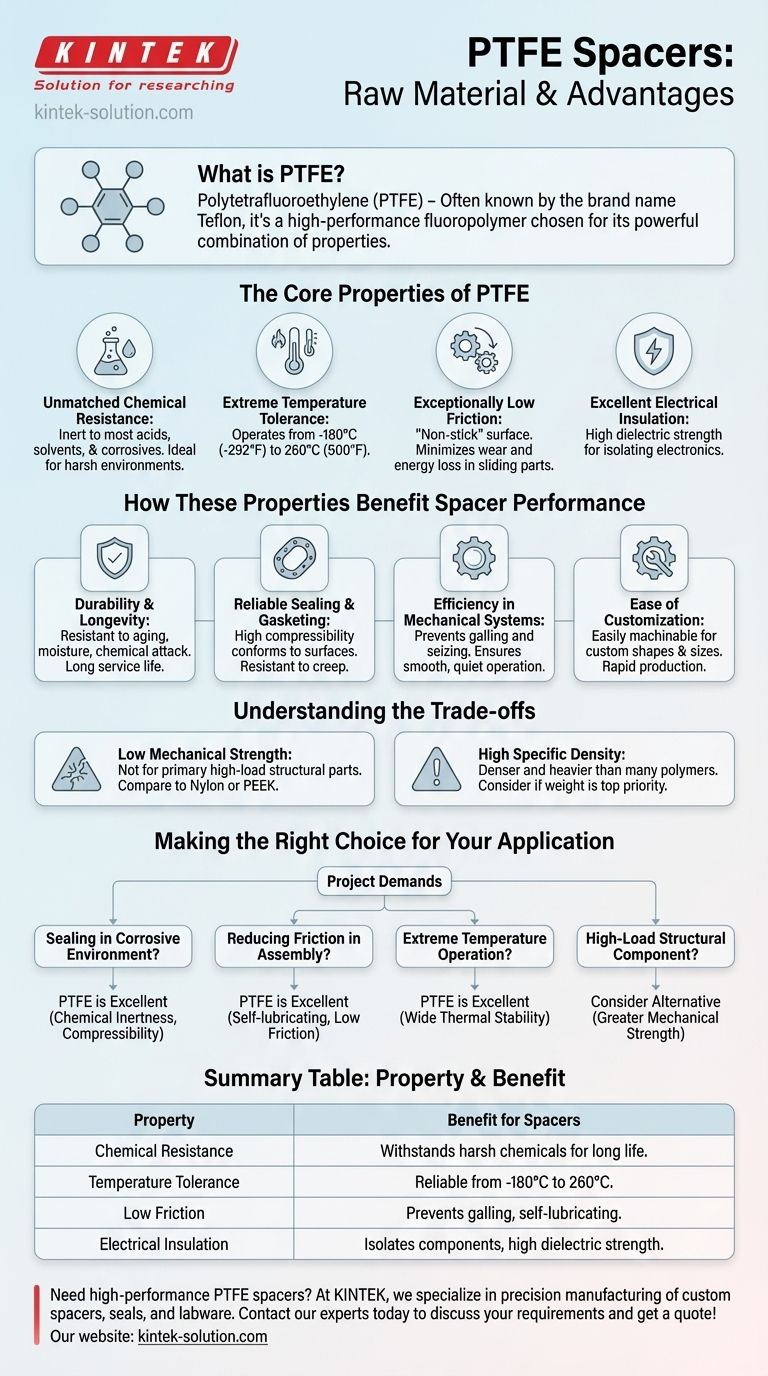

The Core Properties of PTFE

To understand why PTFE spacers are so effective, we must first examine the inherent characteristics of the raw material itself. These properties directly translate to the performance of the final component.

Unmatched Chemical Resistance

PTFE is virtually inert and does not react with most chemicals, including aggressive acids, solvents, and alkali corrosives. This makes it an ideal material for use in chemical processing, laboratories, and any environment with harsh chemical exposure.

Extreme Temperature Tolerance

The material maintains its integrity and performance across an exceptionally wide thermal range. It can operate effectively in cryogenic conditions as low as -180°C (-292°F) and in high-heat environments up to 260°C (500°F).

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any known solid material. This gives it a "non-stick," self-lubricating quality that is critical for applications involving sliding or rotating parts, as it minimizes wear and energy loss.

Excellent Electrical Insulation

As a material with high dielectric strength, PTFE is an outstanding electrical insulator. This property makes its components valuable for isolating electronics and preventing electrical conductivity.

How These Properties Benefit Spacer Performance

The raw material's characteristics give PTFE spacers distinct advantages in real-world applications, moving them beyond simple fillers to critical engineering components.

Durability and Longevity

Because PTFE is resistant to aging, moisture, and chemical attack, spacers made from it have a very long service life. This reduces the need for frequent replacement and maintenance, lowering overall operational costs.

Reliable Sealing and Gasketing

The flexibility and high compressibility of PTFE allow it to conform to surfaces, creating a tight and reliable seal. Its resistance to creep (slow deformation under stress) ensures that the seal remains effective over time, making it invaluable in the seal industry.

Efficiency in Mechanical Systems

In mechanisms with moving parts, the low-friction surface of PTFE spacers prevents galling and seizing. This ensures smooth, quiet operation and improves the overall efficiency of the assembly by reducing drag.

Ease of Customization

PTFE is easily machinable, allowing for the affordable and rapid production of spacers in custom shapes and sizes. This adaptability makes it suitable for both large-scale manufacturing and specialized, on-demand applications.

Understanding the Trade-offs

No material is perfect for every situation. Being a trusted advisor means acknowledging a material's limitations to ensure it is selected for the right reasons.

Low Mechanical Strength

Compared to engineering plastics like nylon or PEEK, PTFE has relatively low tensile strength and rigidity. It is not suitable for high-load structural applications where it would be the primary load-bearing component.

High Specific Density

PTFE is denser and heavier than many other polymers. In applications where minimizing weight is the absolute top priority, this could be a deciding factor against its use.

Making the Right Choice for Your Application

Selecting the correct spacer material depends entirely on the demands of your specific project.

- If your primary focus is sealing in a corrosive environment: PTFE is an excellent choice due to its chemical inertness and compressibility.

- If your primary focus is reducing friction in a moving assembly: The self-lubricating nature and low friction coefficient of PTFE are its key advantages.

- If your primary focus is operating in extreme temperatures: PTFE's wide thermal stability makes it one of the few viable options.

- If your primary focus is a high-load structural component: You should consider a different engineering plastic with greater mechanical strength.

Ultimately, PTFE spacers provide a unique and powerful solution for specialized environments where their combination of properties can overcome significant engineering challenges.

Summary Table:

| Property | Benefit for Spacers |

|---|---|

| Chemical Resistance | Withstands harsh acids, solvents, and corrosives for long-lasting performance. |

| Temperature Tolerance | Operates reliably from -180°C to 260°C (-292°F to 500°F). |

| Low Friction | Self-lubricating surface prevents galling and seizing in moving assemblies. |

| Electrical Insulation | Excellent dielectric strength for isolating electronic components. |

Need high-performance PTFE spacers for your application?

At KINTEK, we specialize in precision manufacturing of PTFE components, including custom spacers, seals, and labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we provide solutions that leverage PTFE's unique properties to solve your toughest engineering challenges.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get the exact component you need.

Contact our experts today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance