Yes, PTFE valves are fundamentally non-toxic. This is a direct result of the material itself—polytetrafluoroethylene (PTFE)—being one of the most chemically inert substances known. Its molecular structure is incredibly stable, meaning it does not react with, absorb, or release substances, making it exceptionally safe for sensitive applications.

The non-toxicity of PTFE is not just a feature; it is the direct outcome of its extreme chemical inertness. This stability prevents it from contaminating the fluids it controls, which is why it is indispensable in industries where purity and safety are non-negotiable.

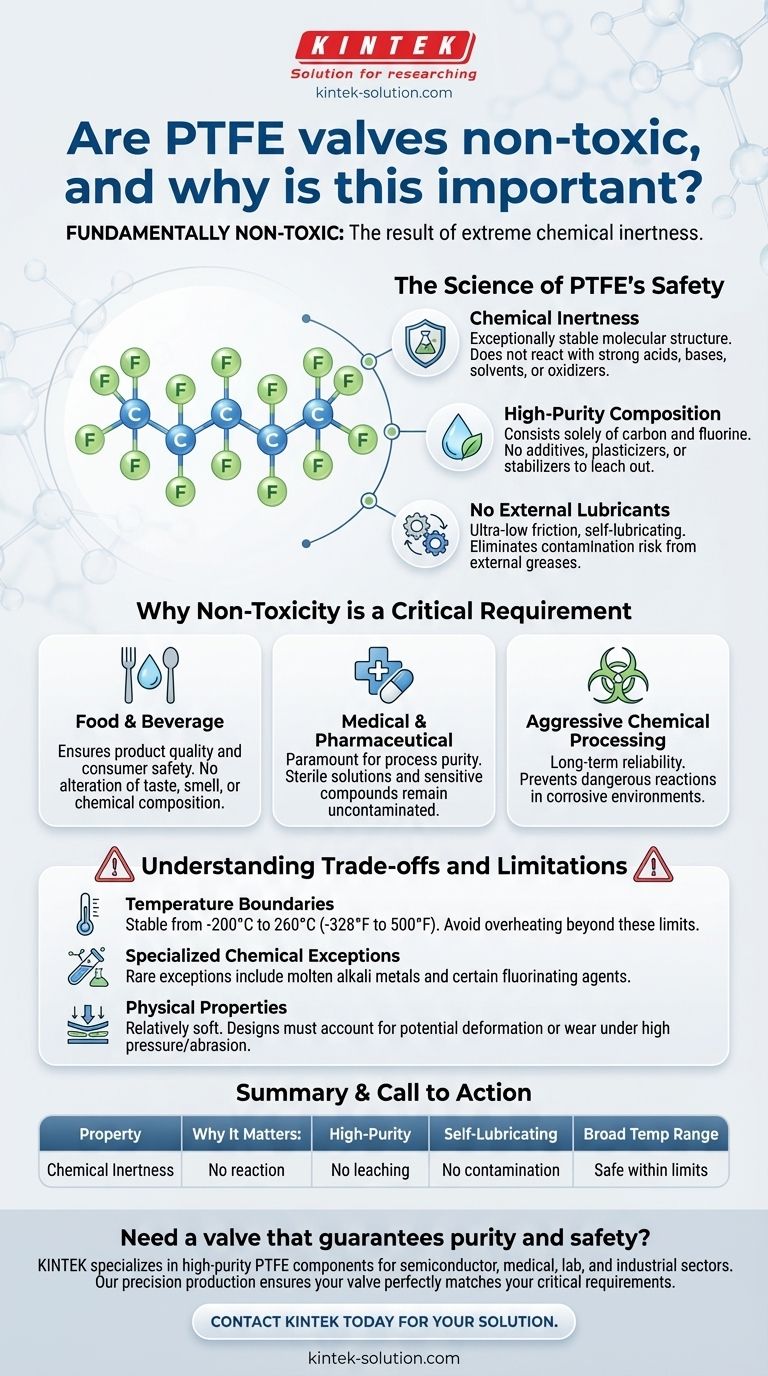

What Makes PTFE a Non-Toxic Material?

The safety of PTFE stems from its unique molecular composition and resulting physical properties. It is engineered for stability, which inherently makes it non-toxic in its solid form within its specified operating range.

The Principle of Chemical Inertness

PTFE is a fluorocarbon polymer, composed of a long chain of carbon atoms completely surrounded by fluorine atoms. The carbon-fluorine bond is exceptionally strong and stable.

This robust molecular structure makes PTFE almost universally resistant to chemical attack. It does not react with strong acids, bases, solvents, or oxidizing agents, ensuring it won't break down and leach harmful byproducts into the process media.

High-Purity Composition

Unlike many other plastics, pure PTFE consists solely of carbon and fluorine. It does not require additives, plasticizers, or stabilizers that could potentially leach out over time.

This inherent purity means that what you put into the valve is exactly what comes out, with no added contaminants from the valve material itself.

No Need for External Lubricants

PTFE has one of the lowest coefficients of friction of any solid, comparable to wet ice on wet ice. This exceptional "slipperiness" is a natural property of the material.

As a result, PTFE valve components operate smoothly without requiring external lubricants, which eliminates a common source of potential chemical or environmental contamination.

Why Non-Toxicity is a Critical Requirement

In many industries, the valve is not just a component for controlling flow; it is a guardian of product purity and safety. The inert nature of PTFE makes it an ideal choice for these critical applications.

Ensuring Purity in Food and Beverage

In food processing, any material that comes into contact with the product must not alter its taste, smell, or chemical composition. PTFE's inability to react or impart any substance makes it a trusted material for ensuring product quality and consumer safety.

Safety in Medical and Pharmaceutical Applications

For medical devices, diagnostic equipment, and pharmaceutical manufacturing, process purity is paramount. PTFE valves ensure that sterile solutions and sensitive chemical compounds remain uncontaminated, which is crucial for patient safety and drug efficacy.

Reliability in Aggressive Chemical Processing

Even outside of sanitary applications, PTFE's inertness is vital. When handling highly corrosive or reactive chemicals, the valve material must not degrade. A non-reactive PTFE valve prevents dangerous reactions and ensures the long-term reliability and safety of the operation.

Understanding the Trade-offs and Limitations

While PTFE is exceptionally stable and non-toxic, it's important to operate within its specified design limits to maintain these properties.

Temperature Boundaries

PTFE is stable over a very wide temperature range, typically from -200°C up to 260°C (-328°F to 500°F). However, if heated well beyond this range toward its melting point of 327°C (621°F), it can begin to decompose and release harmful fluorocarbon gases. It is critical to respect its operational temperature limits.

Specialized Chemical Exceptions

While resistant to nearly all chemicals, the references note that PTFE can be attacked by a few highly reactive substances, such as molten alkali metals and certain fluorinating agents. These are rare, highly specialized industrial exceptions.

Physical and Mechanical Properties

PTFE is a relatively soft material. In applications with high-pressure differentials or abrasive media, valve designs must account for its potential to deform (creep) or wear. This is a mechanical limitation, not a toxicity concern, but is essential for proper application.

Making the Right Choice for Your Application

Selecting a valve material requires matching its properties to your operational goals.

- If your primary focus is consumer safety (food, pharma): PTFE is an industry-standard choice due to its proven inertness and inability to contaminate your product.

- If your primary focus is handling aggressive chemicals: PTFE's nearly universal chemical resistance ensures valve longevity and prevents dangerous reactions with the process media.

- If your primary focus is high-temperature operations: Verify that your process remains well below PTFE's 260°C (500°F) service limit to guarantee material stability and safety.

Understanding these core principles allows you to leverage the exceptional safety and reliability of PTFE with complete confidence.

Summary Table:

| Property | Why It Matters for Non-Toxicity |

|---|---|

| Chemical Inertness | Does not react with process media, preventing contamination. |

| High-Purity Composition | No additives or plasticizers to leach out. |

| Self-Lubricating | No external lubricants needed, eliminating a contamination source. |

| Broad Temperature Range | Stable from -200°C to 260°C, ensuring safety within limits. |

Need a valve that guarantees purity and safety?

KINTEK specializes in manufacturing high-purity PTFE components, including seals, liners, and custom labware, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services, from prototypes to high-volume orders, ensure you get a valve that perfectly matches your application's critical requirements for non-toxicity and chemical resistance.

Contact KINTEK today to discuss your specific needs and ensure the integrity of your process.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications