At their core, PTFE Bellows seals are a specialized type of mechanical seal designed for rotating equipment like pumps and mixers. Their defining feature is a flexible, spring-like bellows made from Polytetrafluoroethylene (PTFE), which provides the closing force and dynamic sealing capability needed to prevent leakage, especially when handling highly corrosive fluids.

A PTFE Bellows seal is the default solution for sealing aggressive or sensitive media where standard materials like elastomers or metals would fail. Its value comes directly from the unique chemical inertness and high-temperature resistance of the PTFE material itself.

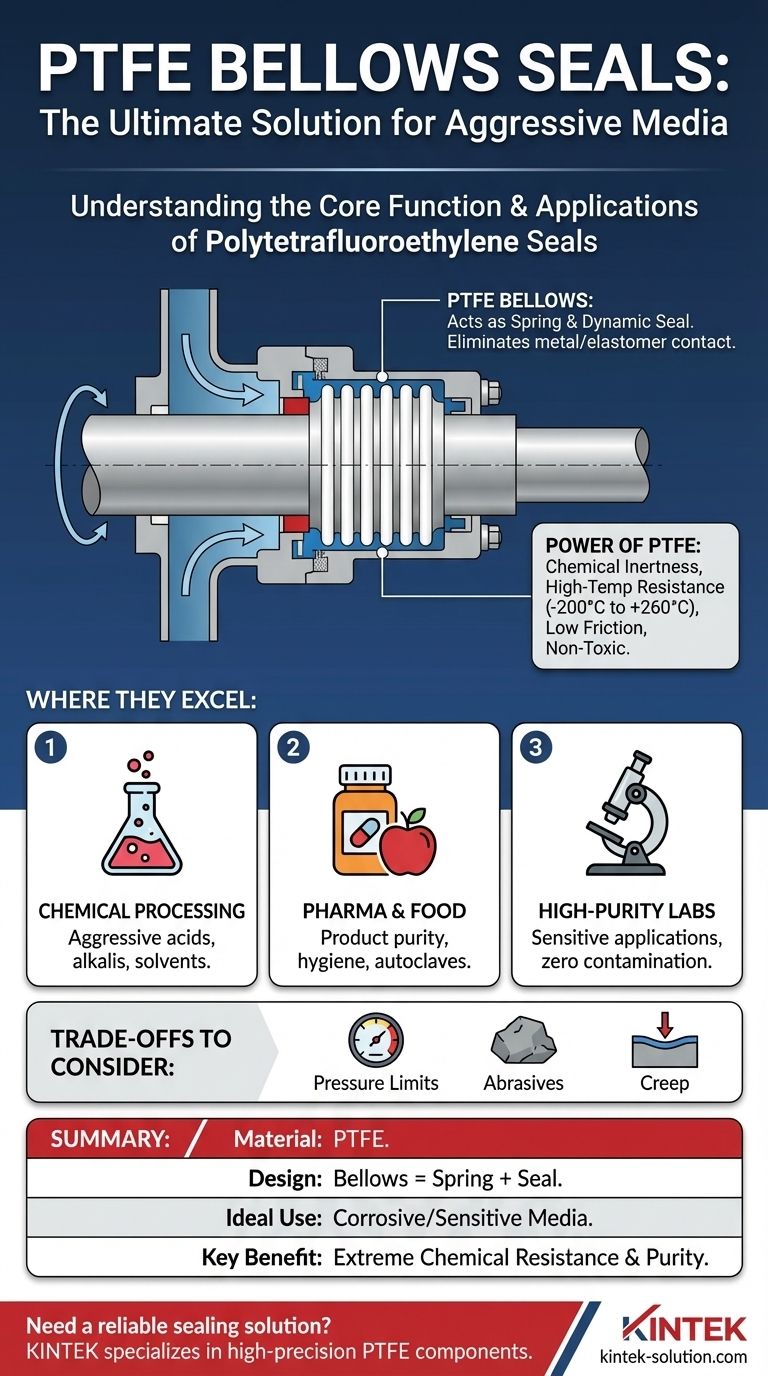

Understanding the Core Function

A mechanical seal's job is to prevent fluid from leaking along the rotating shaft of a pump or mixer. A PTFE Bellows seal accomplishes this through a unique design that leverages the properties of its core material.

The Bellows as a Multi-Function Component

The bellows is the heart of the seal. Unlike conventional seals that use multiple parts like springs and O-rings, the PTFE bellows consolidates these functions.

It acts as both a spring, providing the necessary axial force to keep the seal faces closed, and as a dynamic secondary seal, preventing leakage along the shaft. This elegant design eliminates metal springs and elastomer O-rings from contact with the process fluid, which is critical in corrosive environments.

The Power of Polytetrafluorofluoroethylene (PTFE)

The choice of material is what makes these seals so effective. PTFE, a high-performance fluoropolymer often recognized by the brand name Teflon®, brings several key properties to the table.

- Chemical Inertness: PTFE is non-reactive with nearly all industrial chemicals, acids, and solvents, making it the ideal choice for the most aggressive applications.

- High-Temperature Resistance: It maintains its integrity and properties across a wide range of temperatures, from cryogenic levels up to 260°C (500°F).

- Low Friction: PTFE has one of the lowest coefficients of friction of any solid material, which reduces heat generation and wear between the seal faces.

- Non-Toxicity: It is inherently pure, biocompatible, and does not contaminate the media it contacts, a crucial requirement for specific industries.

Where PTFE Bellows Seals Excel

The unique combination of the bellows design and PTFE material properties makes these seals indispensable in several demanding sectors.

Chemical and Petrochemical Processing

This is the primary domain for PTFE Bellows seals. They are used in pumps, valves, and mixers that handle aggressive substances like strong acids, alkalis, solvents, and other corrosive chemicals where standard seals would quickly degrade and fail.

Pharmaceutical and Food Industries

Because PTFE is non-toxic and compliant with hygiene standards, these seals are essential for maintaining product purity. They are found in equipment like autoclaves, surgical tools, and food processing pumps where contamination is not an option.

High-Purity or Sensitive Applications

Any process that cannot tolerate contamination from metal ions or elastomer breakdown benefits from PTFE. This includes manufacturing electronics, high-purity water systems, and laboratory equipment.

Understanding the Trade-offs

While incredibly versatile, PTFE Bellows seals are not a universal solution. Understanding their limitations is key to proper application.

Pressure and Vacuum Limitations

The inherent flexibility of PTFE means that these bellows seals typically have lower pressure ratings than their metallic counterparts. They are not designed for the very high-pressure hydraulic or pneumatic systems where robust piston seals are more appropriate.

Susceptibility to Abrasives

PTFE is a relatively soft material. If the process fluid contains hard, abrasive particles, the seal faces can wear out prematurely. In such cases, a seal with harder face materials (like silicon carbide) paired with a more robust bellows might be necessary.

Potential for Creep (Cold Flow)

Under sustained mechanical load and temperature, PTFE can slowly deform over time—a phenomenon known as "creep" or "cold flow." Proper seal design and operating within specified pressure and temperature limits are critical to mitigate this effect and ensure a long service life.

Making the Right Choice for Your Application

Selecting the correct seal requires matching its capabilities to your operational demands.

- If your primary focus is extreme chemical resistance: A PTFE Bellows seal is the definitive choice for handling aggressive media where elastomers or standard metals would degrade.

- If your primary focus is product purity and hygiene: The inert, non-toxic, and non-contaminating nature of PTFE makes these seals ideal for pharmaceutical, food, and medical applications.

- If your primary focus is high pressure or abrasive media: You should evaluate metal bellows seals or alternative seal designs with harder face materials, as a standard PTFE bellows may not provide the required durability.

By understanding both the strengths and limitations of PTFE Bellows seals, you can confidently specify the right sealing solution for your equipment.

Summary Table:

| Key Feature | Description | Benefit |

|---|---|---|

| Material | Made from Polytetrafluoroethylene (PTFE) | Extreme chemical inertness and high-temperature resistance |

| Design | Flexible bellows acts as both spring and dynamic seal | Eliminates metal/elastomer contact with fluid, ideal for corrosive media |

| Primary Use | Sealing aggressive or sensitive fluids in pumps and mixers | Prevents leakage and contamination in demanding applications |

| Ideal Industries | Chemical processing, pharmaceuticals, food & beverage, high-purity labs | Ensures safety, purity, and reliability where standard seals fail |

Need a reliable sealing solution for aggressive chemicals or sensitive media?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom bellows seals, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment operates flawlessly with maximum chemical resistance and product purity.

Let us provide the perfect seal for your application: Contact our experts today to discuss your requirements from prototype to high-volume production.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What cooling and lubrication techniques are recommended for PTFE machining? Master Heat Control for Precision Parts

- How is PTFE typically processed in manufacturing? A Guide to Molding, Sintering & Machining

- How are PTFE seals manufactured and customized? Precision CNC Machining for Superior Performance

- Are PTFE slide bearings customizable? Tailor Performance for Your Unique Engineering Challenges

- How does the low friction property of PTFE bushes benefit applications? Extend Component Life and Reduce Maintenance

- What are the limitations of PTFE oil seals, and how are they addressed? Overcome Material Challenges with Engineered Solutions

- Why are PTFE-based materials preferred for RF PCB designs? Achieve Superior Signal Integrity at High Frequencies

- What are the installation advantages of PTFE expansion bellows? Reduce Labor, Time, and Equipment Needs