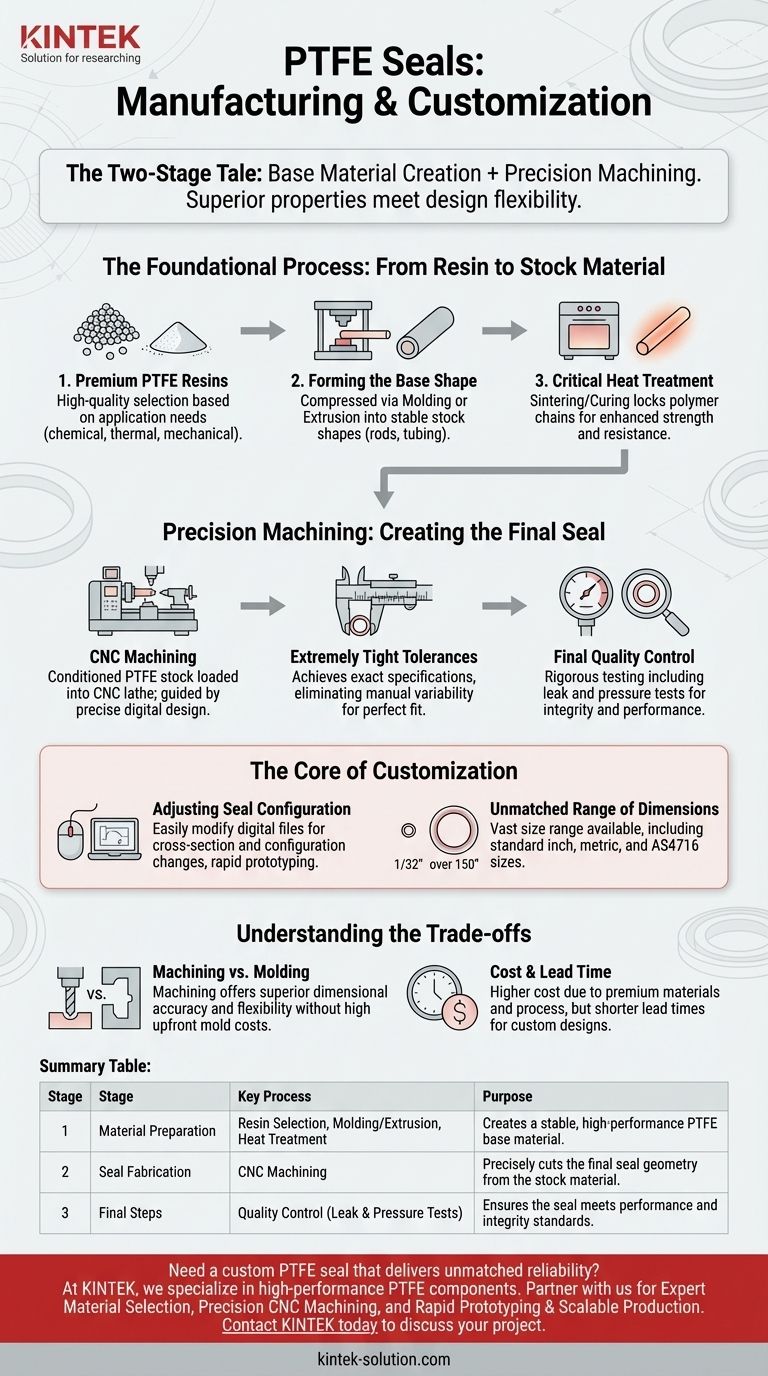

In short, PTFE seals are manufactured by CNC machining them to precise specifications from pre-formed, high-quality PTFE stock. This two-stage process begins by selecting premium PTFE resins, molding or extruding them into a basic shape like tubing, and then applying a critical heat treatment. The final seal is then meticulously carved from this conditioned material using computer-controlled lathes, which allows for immense customization in size and design.

The key takeaway is that the manufacturing of a PTFE seal is a tale of two distinct processes: first, the creation of a stable, high-performance base material, and second, the precision machining that transforms that material into a final, customized component. This separation is what grants PTFE seals both their superior properties and their design flexibility.

The Foundational Process: From Resin to Stock Material

Before a seal can be cut, a high-integrity base material must be created. The quality of this initial stock directly dictates the final performance of the seal.

Step 1: Selecting Premium PTFE Resins

The process begins with the careful selection of high-quality PTFE (Polytetrafluoroethylene) resins. These are chosen in granular or powdered form based on the final application's requirements for chemical resistance, temperature tolerance, and mechanical strength.

Step 2: Forming the Base Shape

The selected resin is then compressed into a basic, workable form, typically solid rods or tubing. This is accomplished through molding (compressing the powder in a mold) or extrusion (forcing the material through a die) to create a consistent stock shape.

Step 3: Critical Heat Treatment

The formed PTFE stock undergoes a crucial heat treatment process, often called curing or sintering. This step locks the polymer chains into place, significantly enhancing the material's mechanical strength, stability, and resistance properties.

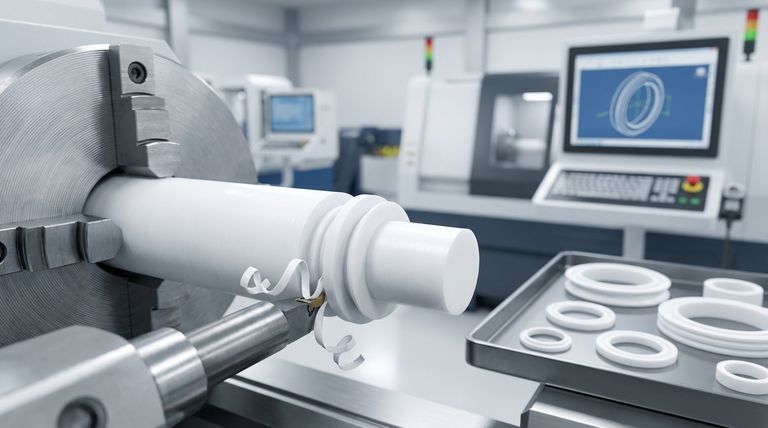

Precision Machining: Creating the Final Seal

With a high-quality stock material prepared, the focus shifts to creating the seal's final, precise geometry. This is where customization occurs.

The Role of CNC Machining

The conditioned PTFE tubing or rod is loaded into a CNC (Computer Numerical Control) lathe. Guided by a precise digital design, the machine cuts away material to form the seal's exact profile, including its lips, grooves, and overall dimensions.

Achieving Extremely Tight Tolerances

This machining process allows for the creation of seals with very close tolerances, ensuring a perfect fit and reliable performance in demanding applications. The computer control eliminates the variability of manual processes.

Final Quality Control

After machining, every seal undergoes rigorous testing. This often includes leak and pressure tests to validate its integrity and ensure it meets the required performance standards before it is ready for use.

The Core of Customization

The reliance on CNC machining is what makes PTFE seals so adaptable. Unlike traditional molded seals, the design is not locked into a physical tool.

Adjusting Seal Configuration

Engineers can easily adjust the digital design file to modify the seal's cross-section or configuration. This flexibility allows for rapid prototyping and performance enhancements tailored to specific operating conditions.

Unmatched Range of Dimensions

This process enables the creation of seals in a vast range of sizes. Diameters can range from as small as 1/32 of an inch to over 150 inches, with equally variable cross-sections, available in standard inch, metric, and AS4716 sizes.

Understanding the Trade-offs

While powerful, the manufacturing process for PTFE seals has specific implications that are important to understand.

Why Machining is Preferred over Molding

For many elastomers, high-volume molding is standard. However, PTFE's unique properties make it difficult to mold into complex final shapes with high precision. Machining offers superior dimensional accuracy and the flexibility to produce custom designs without the high upfront cost of creating a dedicated mold.

Impact on Cost and Lead Time

The use of premium resins and a multi-step manufacturing process, including precision machining, means PTFE seals are typically more expensive than common molded rubber seals. However, because new tooling is not required for each design, lead times for custom designs can be relatively short.

Making the Right Choice for Your Application

Understanding this manufacturing process allows you to specify a seal that perfectly matches your operational needs.

- If your primary focus is maximum performance: Specify the use of premium, virgin PTFE resins and inquire about the heat treatment process to ensure material stability.

- If your primary focus is a unique size or geometry: Leverage the flexibility of CNC machining by providing a precise digital model or drawing of your required profile.

- If your primary focus is extreme chemical or thermal resistance: Start with the inherent properties of the base PTFE, but discuss with your manufacturer if specific fillers can enhance target properties without compromising the seal's integrity.

By understanding how these seals are made, you can better collaborate with manufacturers to design a component that delivers exceptional reliability and longevity.

Summary Table:

| Stage | Key Process | Purpose |

|---|---|---|

| Material Preparation | Resin Selection, Molding/Extrusion, Heat Treatment | Creates a stable, high-performance PTFE base material (rod/tube) |

| Seal Fabrication | CNC Machining | Precisely cuts the final seal geometry from the stock material |

| Final Steps | Quality Control (Leak & Pressure Tests) | Ensures the seal meets performance and integrity standards |

Need a custom PTFE seal that delivers unmatched reliability?

At KINTEK, we specialize in manufacturing high-performance PTFE components like seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our process ensures precision production and custom fabrication from prototypes to high-volume orders.

Partner with us to get:

- Expert Material Selection: We use premium PTFE resins to meet your specific chemical and thermal resistance needs.

- Precision CNC Machining: Achieve exact tolerances and custom geometries without the cost of new tooling.

- Rapid Prototyping & Scalable Production: From a single prototype to a full production run, we deliver quality and consistency.

Contact KINTEK today to discuss your project requirements and receive a quote for seals built to perform.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What material are PTFE envelope gaskets made from? A Guide to Their Composite Construction

- What is the function of PTFE lined check valves? Ensure Unidirectional Flow and Corrosion Resistance

- What CNC techniques are used for machining complex PTFE geometries? Master Precision with Specialized Methods

- What are the main applications of PTFE envelope gaskets? Seal Fragile Flanges and Prevent Contamination

- How does the flexibility of PTFE expansion bellows compare to metal bellows? A Guide to Superior Movement Absorption

- Why are PTFE washers considered cost-effective despite their higher initial cost? Maximize ROI with Long-Term Savings

- How are PTFE sheets utilized in the electrical industry? For Superior Insulation and Signal Integrity

- What are the friction characteristics of PTFE oil seals? Unlock Superior Performance with Low-Friction Seals