The fundamental benefit of PTFE's low friction is its ability to radically reduce wear and tear between moving parts. This property ensures smoother, more consistent movement, which directly translates into longer service life for both the bushing and its mating components, improved operational efficiency, and a significant reduction in maintenance requirements.

The core advantage of a PTFE bush isn't just its slipperiness; it's the cascading effect this has on a system's entire lifecycle. By minimizing friction, you simultaneously boost performance, extend durability, and eliminate the costs and complexities of external lubrication.

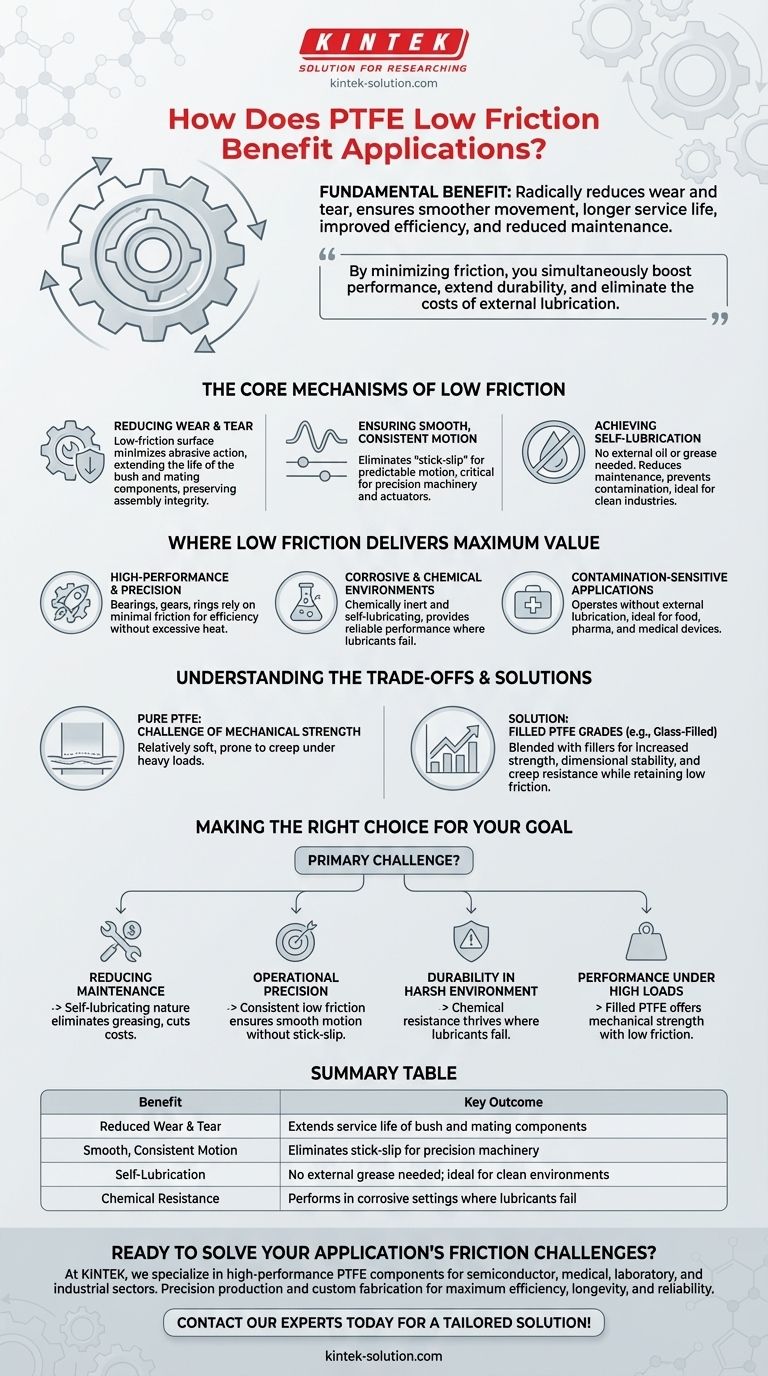

The Core Mechanisms of Low Friction

The exceptionally low coefficient of friction is intrinsic to PTFE's molecular structure. This property drives several key mechanical advantages that make it a superior choice for many demanding applications.

Reducing Wear and Tear

Friction is the primary cause of wear in mechanical systems. As parts slide against each other, friction generates heat and slowly grinds away material, leading to component failure.

PTFE's low-friction surface minimizes this abrasive action. This dramatically extends the life of not only the bush but also the shaft or housing it contacts, preserving the integrity of the entire assembly.

Ensuring Smooth, Consistent Motion

In precision machinery, inconsistent movement ("stick-slip") can ruin performance. PTFE's consistently low friction ensures that motion is always smooth and predictable.

This is critical in applications like slide plates, gears, and precision actuators where accuracy and operational efficiency are paramount.

Achieving Self-Lubrication

Perhaps the most significant operational benefit is that PTFE bushes are self-lubricating. They do not require external oil or grease to function effectively.

This eliminates a major maintenance task, reduces long-term costs, and prevents the risk of contamination from lubricants, which is crucial in food processing, medical, and chemical industries.

Where Low Friction Delivers Maximum Value

While useful in many contexts, the benefits of PTFE's low friction are most pronounced in environments where traditional lubricated metal bearings would quickly fail.

High-Performance and Precision Machinery

Components like bearings, gears, and piston rings rely on minimal friction to operate efficiently without generating excessive heat or losing energy. PTFE provides a built-in advantage, enhancing both performance and longevity.

Corrosive and Chemical Environments

In chemical processing plants or other corrosive environments, lubricants can be washed away, degraded, or react with the surrounding materials.

Because PTFE is both chemically inert and self-lubricating, it provides reliable, long-term performance where other materials cannot.

Contamination-Sensitive Applications

Industries such as food processing, pharmaceuticals, and medical devices cannot tolerate contamination from oils and greases.

PTFE's ability to operate without any external lubrication makes it an ideal material for seals, gaskets, and bearings in these clean environments.

Understanding the Trade-offs

While its low friction is a powerful advantage, it is essential to understand the material's limitations to use it effectively. Pure PTFE is not a universal solution.

The Challenge of Mechanical Strength

Pure, or "virgin," PTFE is a relatively soft material. Under heavy mechanical loads, it can be prone to deformation or "creep," where the material slowly changes shape over time.

The Solution: Filled PTFE Grades

To counteract this, PTFE is often blended with fillers like glass, carbon, or bronze. A glass-filled PTFE bush, for example, offers significantly increased mechanical strength, dimensional stability, and creep resistance.

Crucially, these fillers enhance the material's structural integrity while retaining its excellent low-friction and chemical-resistance properties, creating a powerful composite material.

Making the Right Choice for Your Goal

Selecting the correct bushing material depends entirely on the primary challenge you are trying to solve.

- If your primary focus is reducing maintenance: The self-lubricating nature of PTFE eliminates the need for regular greasing, drastically cutting down on operational costs and labor.

- If your primary focus is operational precision: PTFE's consistent, low coefficient of friction ensures smooth motion without stick-slip, which is critical for sensitive equipment.

- If your primary focus is durability in a harsh environment: The combination of low friction and superior chemical resistance allows PTFE to thrive where lubricants would fail or cause contamination.

- If your primary focus is performance under high loads: A glass-filled or other composite PTFE offers the necessary mechanical strength while preserving the core low-friction benefit.

By leveraging its unique properties, you can design mechanical systems that are more efficient, reliable, and durable.

Summary Table:

| Benefit | Key Outcome |

|---|---|

| Reduced Wear & Tear | Extends service life of bush and mating components |

| Smooth, Consistent Motion | Eliminates stick-slip for precision machinery |

| Self-Lubrication | No external grease needed; ideal for clean environments |

| Chemical Resistance | Performs in corrosive settings where lubricants fail |

Ready to solve your application's friction and wear challenges?

At KINTEK, we specialize in manufacturing high-performance PTFE components—including seals, liners, and custom bushings—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services, from prototypes to high-volume orders, ensure you get a component that delivers maximum efficiency, longevity, and reliability.

Contact our experts today to discuss your specific requirements and get a tailored solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech