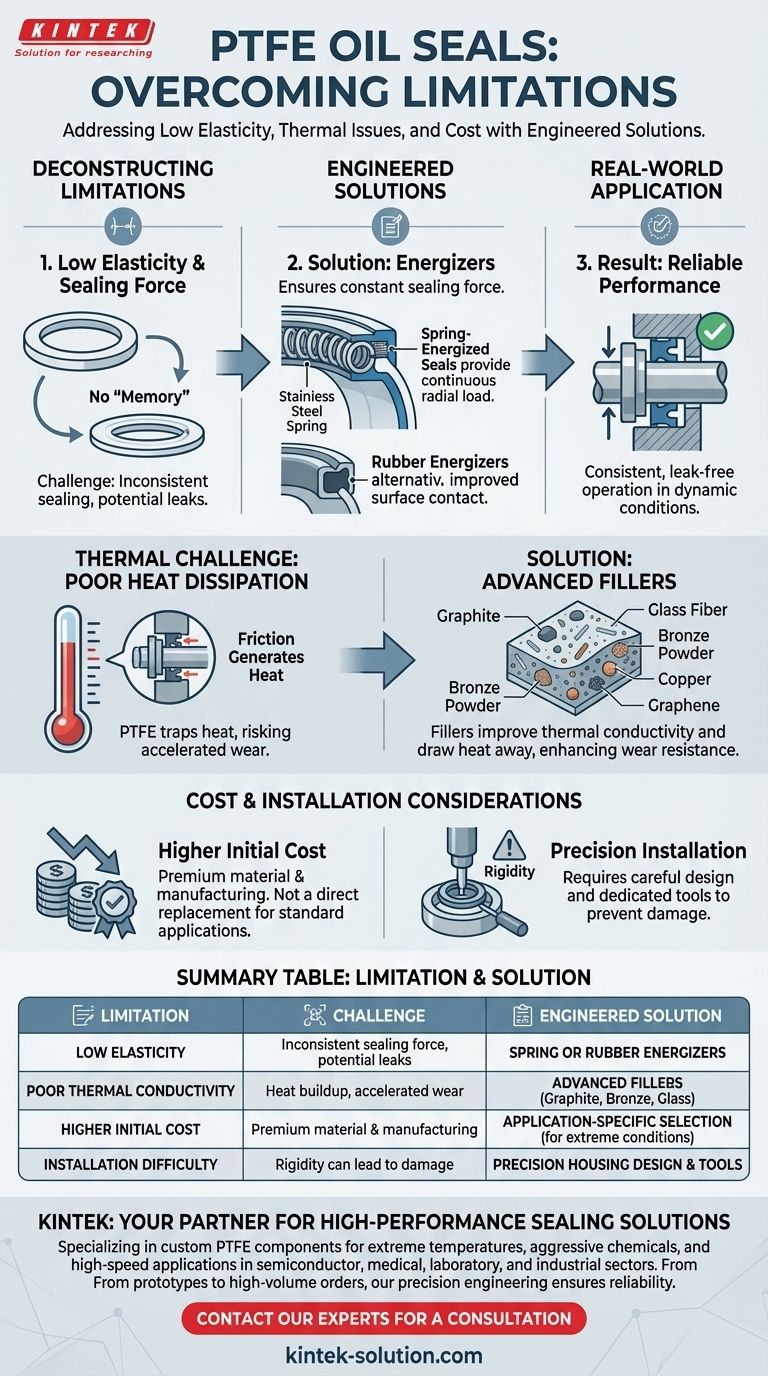

While valued for exceptional performance in extreme conditions, the primary limitations of PTFE oil seals are their low elasticity, poor thermal conductivity, and higher initial cost. These inherent material challenges are not prohibitive; instead, they are addressed through specific engineering solutions like integrated energizing springs and the use of advanced composite fillers.

The limitations of PTFE seals are not deal-breakers but rather known engineering variables. Their material rigidity and poor heat dissipation are effectively overcome with clever design modifications, making them a superior choice for critical applications where standard elastomeric seals would inevitably fail.

Deconstructing the Core Limitations

To properly evaluate a PTFE seal, you must first understand the fundamental properties of the material itself and how they differ from traditional rubber compounds.

The Elasticity Problem: Rigidity and Sealing Force

PTFE is a plastic, not an elastomer. Unlike rubber, it does not have inherent "memory" or the ability to rebound after being compressed.

This low elasticity means a pure PTFE seal may not maintain consistent, tight contact with a shaft, potentially leading to leaks or bypass, especially under variable conditions.

The Thermal Challenge: Poor Heat Dissipation

Friction between the seal lip and a rotating shaft generates heat. PTFE is a poor thermal conductor, meaning it tends to trap this heat at the point of contact.

Without a way to dissipate this thermal energy, excessive temperatures can build up, potentially accelerating wear and reducing the seal's operational life.

The Cost Factor: A Premium Material

The raw materials and manufacturing processes for high-performance PTFE seals are more complex and expensive than those for standard nitrile or viton seals.

This higher upfront cost means they are not a direct replacement for every application but are reserved for situations where their unique benefits justify the investment.

Engineered Solutions for Overcoming Weaknesses

The modern PTFE seal is rarely just a simple ring of PTFE. It is an engineered system designed specifically to compensate for the material's natural limitations.

Solution for Low Elasticity: Energizers

To ensure a constant sealing force, most PTFE seals incorporate an energizer.

The most common design is a spring-energized seal, which uses a stainless steel spring embedded in the seal lip to provide a continuous radial load against the shaft. Rubber energizers can also be used to improve surface contact.

Solution for Thermal Issues: Advanced Fillers

To improve thermal conductivity and mechanical strength, PTFE is often blended with fillers. This creates a "filled" or "modified" PTFE composite.

Common fillers include graphite, glass fiber, bronze powder, copper, or graphene. These additives help draw heat away from the sealing lip and enhance the material's resistance to wear.

Solution for Installation: Design Considerations

The rigidity of PTFE can make installation more difficult than with flexible rubber seals. Forcing a PTFE seal can damage the lip, leading to immediate failure.

This is solved through careful design of the housing and installation tools. Features like flanges or dedicated retainers are often used to ensure the seal is installed correctly and without damage.

Understanding the Trade-offs

Choosing a PTFE seal is a matter of weighing its unparalleled performance benefits against its specific engineering requirements.

Performance vs. Cost

The decision is straightforward: you invest in a PTFE seal when the operational conditions are too extreme for a standard elastomer.

This includes applications with high temperatures (up to 260°C / 500°F), aggressive chemicals, high shaft speeds, or the need for dry-running capability. In these cases, the higher cost prevents far more expensive equipment failure.

Forgiveness vs. Precision

Elastomeric seals are generally more forgiving of minor shaft imperfections and slight misalignments.

PTFE seals demand greater precision. For optimal performance, they require a well-prepared shaft surface and careful, precise installation. When these conditions are met, their lifespan and reliability are exceptional.

Making the Right Choice for Your Application

Selecting the correct seal requires matching the material's capabilities to your primary operational goal.

- If your primary focus is extreme temperature or chemical resistance: A filled or spring-energized PTFE seal is the definitive choice, and the higher cost is a necessary investment in reliability.

- If your primary focus is a standard, cost-sensitive application: A traditional elastomeric seal is likely the more practical and forgiving option for moderate operating conditions.

- If you need high performance in a dry-running or high-speed environment: PTFE's low-friction properties make it superior to any rubber-based alternative.

By understanding these limitations and their corresponding solutions, you can confidently specify the right sealing technology for your most demanding applications.

Summary Table:

| Limitation | Primary Challenge | Engineered Solution |

|---|---|---|

| Low Elasticity | Inconsistent sealing force, potential leaks | Spring or Rubber Energizers for constant radial load |

| Poor Thermal Conductivity | Heat buildup at sealing lip, accelerated wear | Advanced Fillers (graphite, bronze, glass) to dissipate heat |

| Higher Initial Cost | Premium material and manufacturing | Application-Specific Selection for extreme conditions where cost is justified |

| Installation Difficulty | Rigidity can lead to damage during installation | Precision Housing Design and dedicated installation tools |

Facing extreme temperatures, aggressive chemicals, or high-speed applications? Standard elastomeric seals often fail under these conditions. KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision engineering and custom fabrication capabilities, from prototypes to high-volume orders, ensure you get a reliable sealing solution designed for your specific operational challenges.

Let's engineer a solution for your most demanding applications. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs