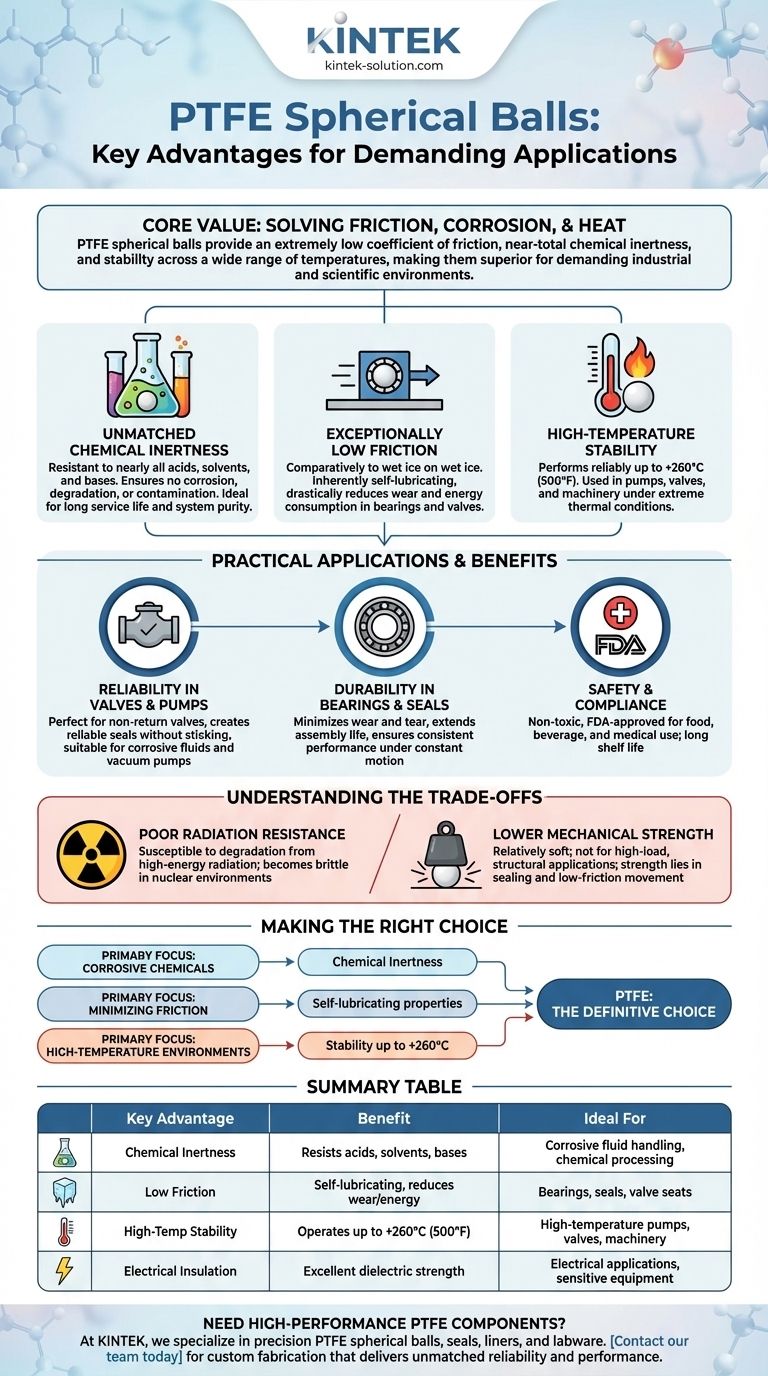

At their core, Polytetrafluoroethylene (PTFE) spherical balls provide a powerful combination of three key advantages: an extremely low coefficient of friction, near-total chemical inertness, and stability across a wide range of temperatures. This unique blend of properties makes them a superior choice for components in demanding industrial and scientific environments where other materials would quickly degrade or fail.

The fundamental value of PTFE balls lies in their ability to solve problems of friction, corrosion, and heat simultaneously. They are not chosen for strength, but for their unrivaled reliability and longevity in chemically aggressive or high-temperature, self-lubricating applications.

The Core Properties Defining PTFE Performance

To understand why PTFE balls are specified for critical applications, we must first examine the material's foundational characteristics. These properties work in concert to deliver exceptional performance.

Unmatched Chemical Inertness

PTFE is resistant to nearly all chemicals, including aggressive acids, solvents, and bases. This makes it an ideal material for components that are in constant contact with corrosive substances.

This property ensures the ball will not corrode, degrade, or contaminate the media it is in, leading to a significantly longer service life and system purity.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This inherent lubricity means it requires no external lubrication.

In applications like bearings or valve seats, this self-lubricating nature drastically reduces wear on moving parts and lowers the energy required to operate the system.

High-Temperature Stability

PTFE balls perform reliably across a very wide temperature range, with a continuous working temperature of up to +260°C (500°F).

This high heat resistance allows them to be used in pumps, valves, and machinery operating in extreme thermal conditions where most other plastics would melt or deform.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with very high dielectric strength. This property is critical in applications where the ball must prevent the flow of electricity or the buildup of static charge.

Practical Applications and Benefits

These core properties translate directly into tangible advantages in real-world applications, enhancing efficiency, safety, and reliability.

Reliability in Valves and Pumps

The chemical inertness and low density of PTFE balls make them perfectly suited for non-return (check) valves, especially in vacuum pumps or systems handling corrosive fluids. They create a reliable seal without sticking or degrading.

Durability in Bearings and Seals

In bearings and seals, the low-friction surface minimizes wear and tear, extending the life of the entire assembly. Their durability ensures consistent performance under constant motion.

Safety and Compliance

PTFE is non-toxic and can be FDA-approved for use in food, beverage, and medical applications. Its long shelf life and resistance to degradation ensure it remains safe and stable over time.

Understanding the Trade-offs

While PTFE is an exceptional material, no single solution is perfect for every scenario. Acknowledging its limitations is key to using it effectively.

Poor Radiation Resistance

PTFE is susceptible to degradation when exposed to high-energy radiation. The material can become brittle and lose its desirable properties, making it unsuitable for applications in nuclear or high-radiation environments.

Lower Mechanical Strength

Compared to metals or ceramics, PTFE is a relatively soft material. It is not designed for high-load, structural applications where compressive strength and rigidity are the primary requirements. Its strength lies in sealing and low-friction movement, not load-bearing.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the primary challenge you need to solve.

- If your primary focus is handling corrosive chemicals: PTFE is the definitive choice due to its near-total chemical inertness, preventing component failure and fluid contamination.

- If your primary focus is minimizing friction in a mechanical system: PTFE’s self-lubricating properties provide an ideal solution for creating low-wear, high-efficiency bearings, seals, and valve seats.

- If your primary focus is operating in high-temperature environments: PTFE’s stability up to +260°C ensures reliable performance where other plastics would fail, making it perfect for demanding industrial processes.

Ultimately, PTFE spherical balls are the go-to engineering solution for challenges that demand exceptional material resilience.

Summary Table:

| Key Advantage | Benefit | Ideal For |

|---|---|---|

| Chemical Inertness | Resists nearly all acids, solvents, and bases | Corrosive fluid handling, chemical processing |

| Low Friction | Self-lubricating, reduces wear and energy use | Bearings, seals, valve seats |

| High-Temp Stability | Operates reliably up to +260°C (500°F) | High-temperature pumps, valves, industrial machinery |

| Electrical Insulation | Excellent dielectric strength, prevents static buildup | Electrical applications, sensitive equipment |

Need high-performance PTFE components tailored to your specific challenges?

At KINTEK, we specialize in manufacturing precision PTFE spherical balls, seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get components that deliver unmatched reliability, longevity, and performance in even the most demanding environments.

Let us help you solve problems of friction, corrosion, and heat. Contact our team today to discuss your requirements!

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- In which industries are PTFE mill-type envelope gaskets applied? Ensure Leak-Free Sealing in Demanding Environments

- What are the advantages of PTFE envelope gaskets in flange connections? Seal Sensitive Flanges with Low Bolt Load

- Do PTFE backups provide chemical resistance to rubber O-rings? The Surprising Truth About Seal Protection

- How does PTFE perform in cryogenic applications? Maintain Performance in Extreme Cold

- What are PTFE bearing pads and what are their main features? The Ultimate Guide to Low-Friction Structural Support

- Why is Teflon particularly suitable for medical and food processing applications? Unmatched Purity & Performance

- What are the characteristics of PTFE spherical balls? Key Properties for Demanding Applications

- What is the role of Teflon backup rings in sealing technology? Prevent Seal Extrusion & Boost Reliability