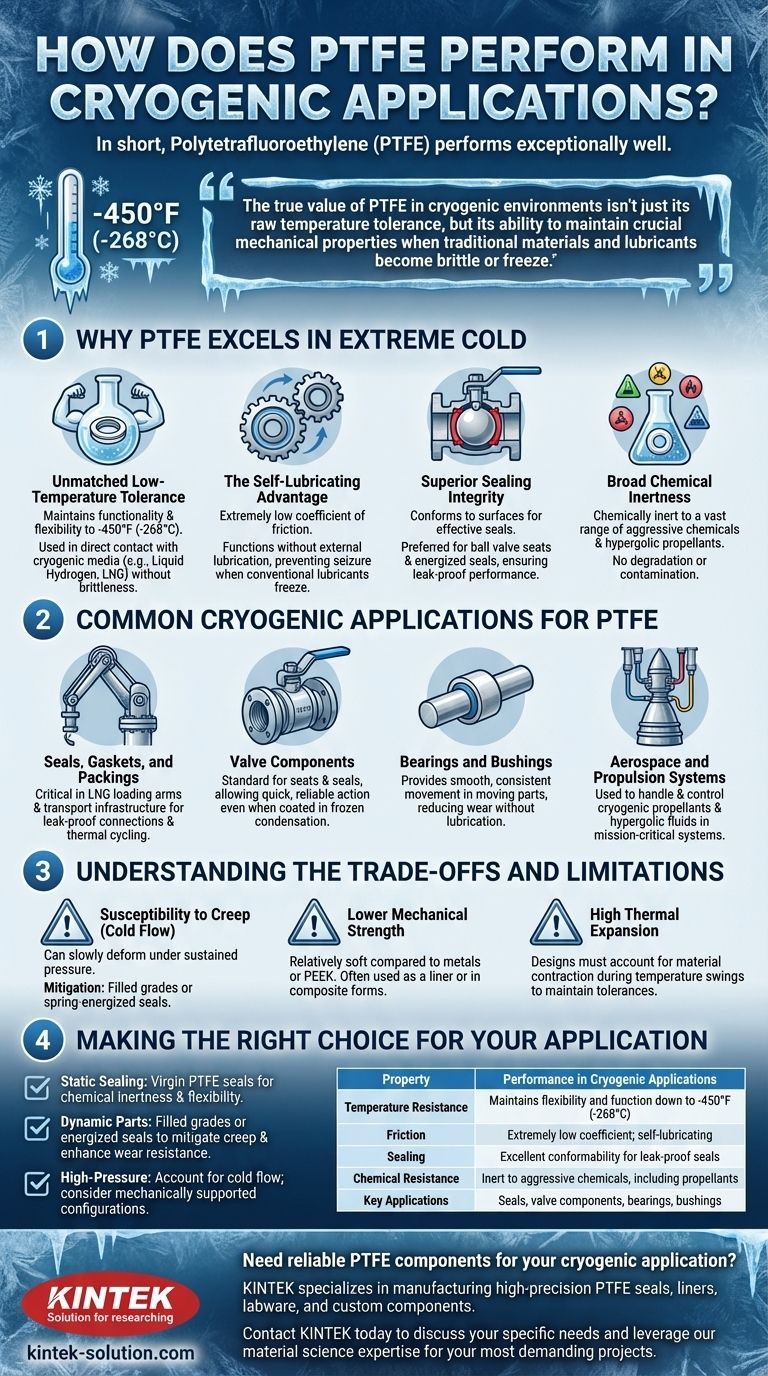

In short, Polytetrafluoroethylene (PTFE) performs exceptionally well in cryogenic applications. It can withstand temperatures as low as -450°F (-268°C) and is frequently used with super-cooled media like liquid hydrogen and compressed natural gas. Its unique combination of extremely low friction, chemical inertness, and reliable sealing capability makes it a primary choice for critical components where other materials would fail.

The true value of PTFE in cryogenic environments isn't just its raw temperature tolerance, but its ability to maintain crucial mechanical properties when traditional materials and lubricants become brittle or freeze. This ensures reliable sealing and smooth operation under the most extreme conditions.

Why PTFE Excels in Extreme Cold

PTFE's molecular structure gives it a unique set of characteristics that make it highly suitable for service at temperatures approaching absolute zero. Understanding these properties is key to leveraging the material effectively.

Unmatched Low-Temperature Tolerance

PTFE maintains its functionality and flexibility at temperatures down to -450°F (-268°C). This allows it to be used in direct contact with cryogenic media like liquid hydrogen and LNG without becoming brittle or cracking, a common failure point for many other polymers.

The Self-Lubricating Advantage

At cryogenic temperatures, conventional lubricants freeze and become ineffective. PTFE has an extremely low coefficient of friction, one of the lowest of any solid material, allowing it to function without any external lubrication. This "self-lubricating" property is critical for preventing mechanical parts from seizing.

Superior Sealing Integrity

PTFE's flexibility allows it to conform to surfaces, creating a highly effective seal. This makes it a preferred choice for components like ball valve seats and energized seals used in the transport and handling of cryogenic fluids, where preventing leaks is a matter of safety and efficiency.

Broad Chemical Inertness

Many cryogenic fluids, such as hypergolic propellants used in aeronautics, are highly reactive. PTFE is chemically inert to a vast range of aggressive chemicals, including acids, bases, and solvents. This ensures that components do not degrade or contaminate the media they are handling.

Common Cryogenic Applications for PTFE

The unique properties of PTFE have made it indispensable in several high-stakes industries that operate at extremely low temperatures.

Seals, Gaskets, and Packings

These are the most common applications. PTFE seals are critical in systems like LNG loading arms and other infrastructure for transporting cryogenic liquids, ensuring a leak-proof connection that can withstand thermal cycling.

Valve Components

PTFE is the standard material for seats and seals in cryogenic ball valves. Its ability to create a tight seal and operate with low friction allows for quick and reliable valve action even when coated in frozen condensation.

Bearings and Bushings

For mechanical equipment with moving parts that operate in a cryogenic environment, PTFE bearings and bushings provide smooth, consistent movement without lubrication. This reduces wear on mating surfaces and extends the operational life of the equipment.

Aerospace and Propulsion Systems

In aeronautics, PTFE components are used to handle and control the flow of cryogenic propellants and hypergolic fluids. Its reliability and chemical resistance are paramount in these mission-critical systems.

Understanding the Trade-offs and Limitations

While highly effective, PTFE is not a universal solution. An objective technical assessment requires acknowledging its limitations in certain engineering contexts.

Susceptibility to Creep (Cold Flow)

Under sustained pressure, especially at warmer temperatures, PTFE can slowly deform or "creep." This must be accounted for in the design of high-load applications. Using filled grades of PTFE or spring-energized seals can help mitigate this effect.

Lower Mechanical Strength

Compared to metals or other engineered plastics like PEEK, virgin PTFE is a relatively soft material with lower tensile strength and wear resistance. It is often used as a liner or in composite forms rather than as a primary structural component.

High Thermal Expansion

PTFE has a relatively high coefficient of thermal expansion. Designs for components that will experience a wide temperature swing from ambient to cryogenic must carefully account for the material's contraction to maintain proper tolerances and sealing pressure.

Making the Right Choice for Your Application

Choosing the right material configuration depends entirely on the specific demands of your system.

- If your primary focus is static sealing of cryogenic fluids: Virgin PTFE seals and gaskets offer an excellent combination of chemical inertness and low-temperature flexibility.

- If your application involves dynamic or moving parts (like valves or bearings): Consider filled grades of PTFE or energized seals to mitigate creep and enhance wear resistance under load.

- If you are dealing with high-pressure systems: Ensure your design accounts for PTFE's potential for cold flow, possibly by using it in mechanically supported configurations.

By understanding these properties, you can confidently leverage PTFE to ensure reliability and longevity in the most demanding cryogenic environments.

Summary Table:

| Property | Performance in Cryogenic Applications |

|---|---|

| Temperature Resistance | Maintains flexibility and function down to -450°F (-268°C) |

| Friction | Extremely low coefficient of friction; self-lubricating when other lubricants fail |

| Sealing | Excellent conformability for reliable, leak-proof seals and gaskets |

| Chemical Resistance | Inert to a vast range of aggressive chemicals, including cryogenic propellants |

| Key Applications | Seals, valve components (seats), bearings, and bushings for LNG, aerospace, and lab systems |

Need reliable PTFE components for your cryogenic application?

KINTEK specializes in manufacturing high-precision PTFE seals, liners, labware, and custom components that perform under extreme conditions. Whether you require prototypes or high-volume orders for the semiconductor, medical, laboratory, or industrial sectors, our expertise ensures your systems operate with integrity and safety.

Contact KINTEL today to discuss your specific needs and leverage our material science expertise for your most demanding projects.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications