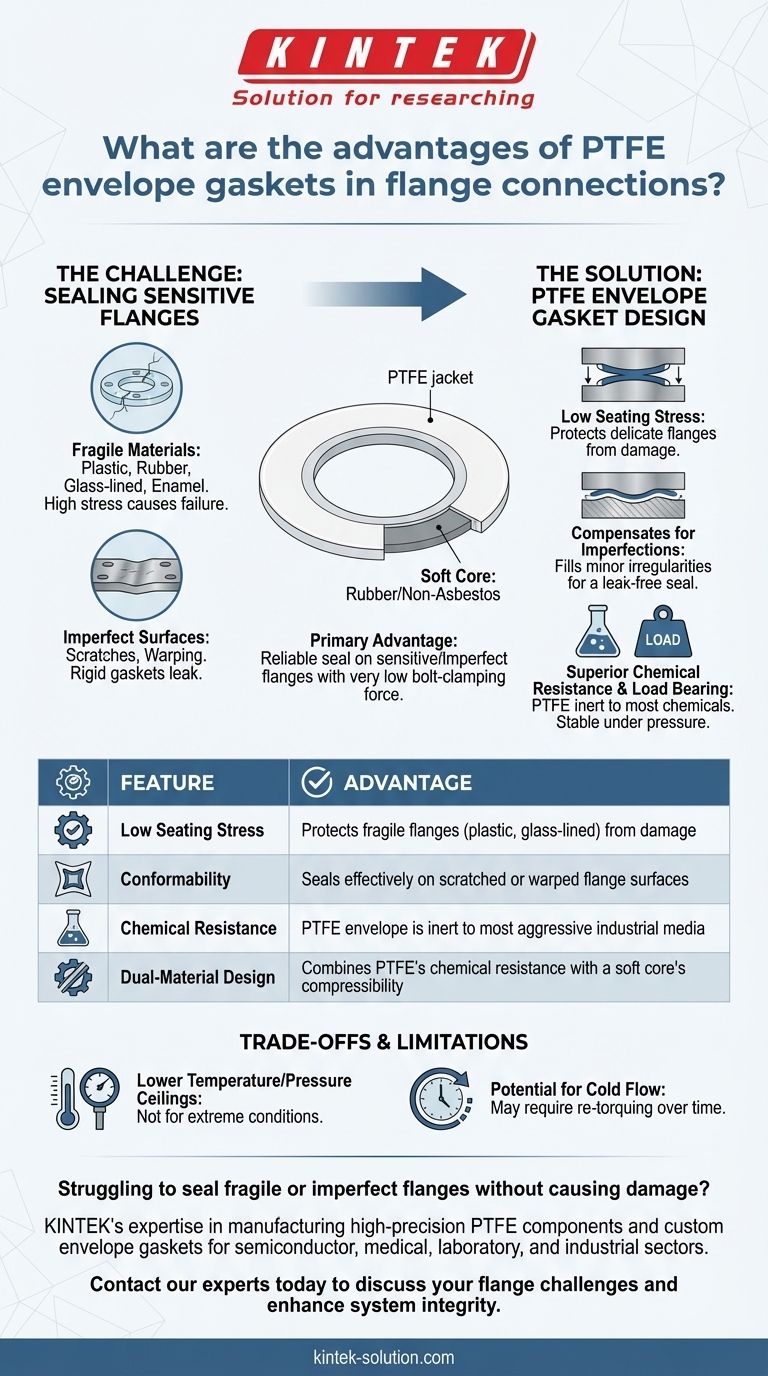

The primary advantage of a PTFE envelope gasket is its unique ability to create a reliable, tight seal on sensitive or imperfect flanges with very low bolt-clamping force. It combines the superior chemical resistance of PTFE with the compressibility of a softer core material, solving sealing challenges where other gaskets would fail or cause damage.

A PTFE envelope gasket is a problem-solver for specialty applications. It leverages a dual-material design to seal fragile, uneven, or chemically aggressive flange connections that cannot tolerate the high compressive loads required by standard gaskets.

The Challenge of Sealing Sensitive Flanges

Many industrial applications use piping and equipment with flanges that are easily damaged. Sealing these connections presents a significant engineering challenge that standard gaskets are often ill-equipped to handle.

Fragile Flange Materials

Flanges made from materials like plastic, rubber, or glass-lined and enameled steel are highly susceptible to cracking or deformation under high stress.

Applying the bolt load needed to compress a typical solid gasket can easily destroy these fragile flange faces, leading to costly failures and downtime.

Imperfect Sealing Surfaces

In the real world, not all flange faces are perfectly flat. They can have minor scratches, warping, or other surface unevenness.

A rigid gasket may not be able to conform to these small imperfections, creating leak paths. This forces technicians to overtighten bolts in an attempt to close the gaps, again risking damage to the flange.

How the PTFE Envelope Gasket Solves the Problem

The PTFE envelope gasket’s design directly addresses these challenges by separating the functions of chemical resistance and compressibility into two different materials.

The Dual-Material Advantage

This gasket consists of a soft, conformable insert material (like non-asbestos or rubber) enclosed within a thin "envelope" or jacket of PTFE.

The PTFE provides the chemically inert, low-friction sealing surface that contacts the process fluid. The inner core provides the soft, compressible body needed to create the seal.

Sealing with Low Seating Stress

The soft core material allows the gasket to achieve a tight seal with minimal surface compression.

This low bolt torque requirement is the key feature that protects delicate plastic, enamel, or rubber flanges from being crushed or damaged during installation.

Compensating for Flange Imperfections

The gasket's inherent flexibility allows it to flow into and fill minor flange irregularities.

Instead of bridging over scratches or pits, the compressible core enables the PTFE envelope to conform precisely to the flange face, ensuring a leak-free connection even on less-than-perfect surfaces.

Superior Chemical Resistance and Load Bearing

The outer PTFE layer is virtually inert to most industrial chemicals, preventing degradation and ensuring purity.

Once compressed, the contained core gives the gasket excellent stability, allowing it to withstand system pressure without blowing out and effectively bear the load across the joint.

Understanding the Trade-offs

While highly effective, PTFE envelope gaskets are not a universal solution. Their unique construction comes with specific limitations that are critical to understand.

Temperature and Pressure Ceilings

PTFE has a lower maximum temperature limit than materials like graphite or metal. They are generally not suited for high-temperature services.

Similarly, while robust, they are typically used in low-to-moderate pressure applications. Very high-pressure systems often require metallic or spiral-wound gaskets.

Potential for Cold Flow

PTFE as a material can be susceptible to creep, or "cold flow," over time, especially under cyclic temperature and pressure conditions. This can lead to a loss of bolt torque.

For this reason, connections using these gaskets may require periodic re-torquing to maintain a reliable seal throughout their service life.

Making the Right Choice for Your Application

Selecting the correct gasket is about matching its capabilities to your specific operational needs.

- If your primary focus is sealing fragile flanges (plastic, glass-lined, enamel): This gasket is the ideal choice, as it prevents damage by requiring minimal bolt force to seal.

- If you are dealing with slightly warped or uneven flange faces: The conformability of the soft core provides a reliable seal where more rigid gaskets would likely fail.

- If your priority is chemical compatibility with aggressive media: The PTFE jacket offers a nearly universal inert sealing surface for a wide range of applications.

- If your system involves extreme high pressure or high temperature: You should evaluate more robust alternatives, such as spiral wound or metallic gaskets.

Ultimately, the PTFE envelope gasket is a precision solution designed to ensure integrity in common but critical sealing scenarios.

Summary Table:

| Feature | Advantage |

|---|---|

| Low Seating Stress | Protects fragile flanges (plastic, glass-lined) from damage |

| Conformability | Seals effectively on scratched or warped flange surfaces |

| Chemical Resistance | PTFE envelope is inert to most aggressive industrial media |

| Dual-Material Design | Combines PTFE's chemical resistance with a soft core's compressibility |

| Limitations | Lower temperature/pressure limits than metal gaskets; potential for cold flow |

Struggling to seal fragile or imperfect flanges without causing damage? KINTEK specializes in manufacturing high-precision PTFE components, including custom envelope gaskets designed for sensitive applications in the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a reliable, leak-free seal that protects your equipment and extends its service life.

Contact our experts today to discuss your specific flange connection challenges and discover how our custom PTFE solutions can enhance your system's integrity and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications