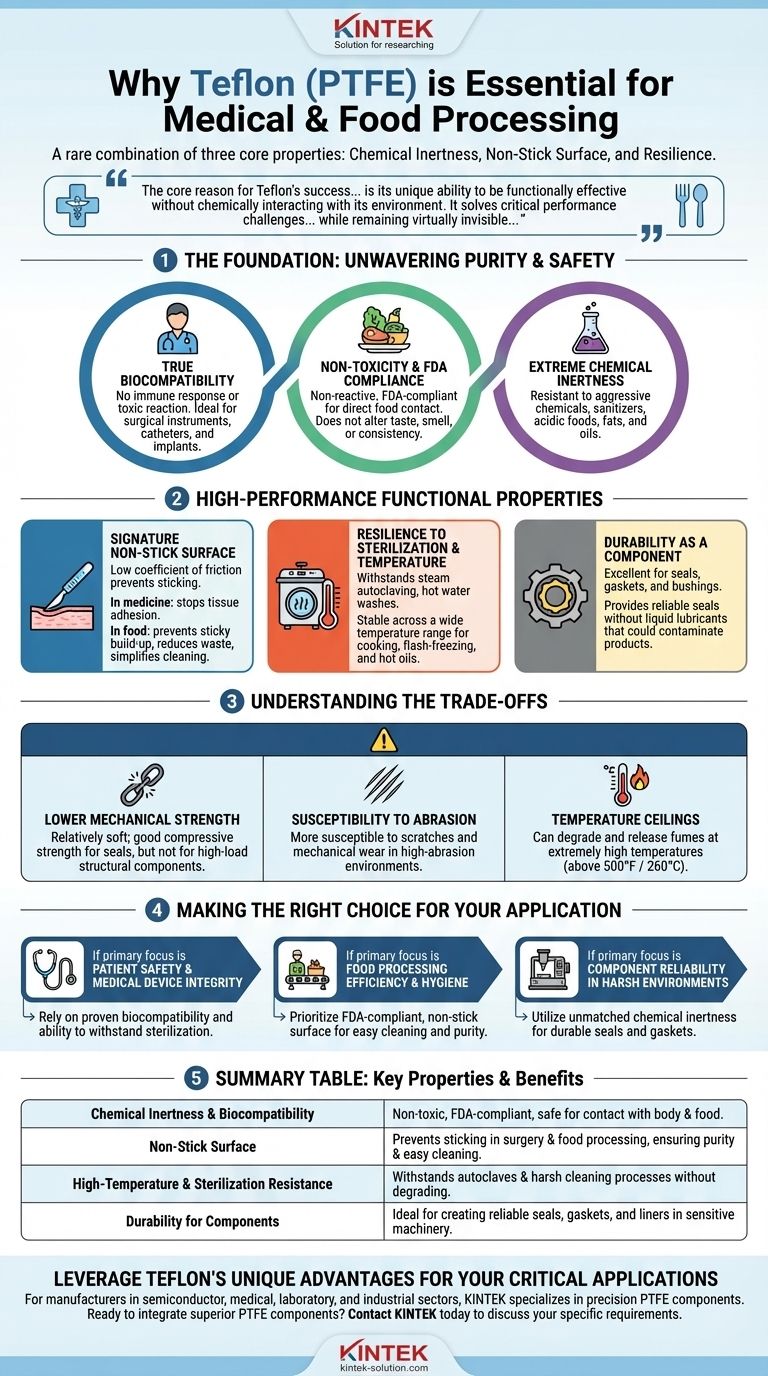

The suitability of Teflon for medical and food processing is not accidental; it stems from a rare combination of three core properties. Its profound chemical inertness makes it non-toxic and biocompatible, its non-stick surface ensures purity and ease of cleaning, and its resilience allows it to withstand the extreme temperatures and sterilization processes common in these demanding fields.

The core reason for Teflon's success in sensitive applications is its unique ability to be functionally effective without chemically interacting with its environment. It solves critical performance challenges—like friction and adhesion—while remaining virtually invisible to the human body and food products.

The Foundation: Unwavering Purity and Safety

For any material to be used in medical devices or food-grade machinery, its first and most important characteristic must be safety. Teflon (PTFE) excels here by being fundamentally non-reactive.

True Biocompatibility

The term biocompatible means the material does not provoke an immune response or toxic reaction when exposed to the body or bodily fluids.

Teflon is one of the most biocompatible polymers known, making it ideal for surgical instruments, catheters, and even permanent implants like ligament replacements. The body simply does not recognize it as a foreign substance.

Non-Toxicity and FDA Compliance

In food processing, the primary concern is preventing chemical contamination. Teflon's inert nature means it does not leach harmful substances into food products.

This property is validated by its status as an FDA-compliant material, which certifies its safety for direct contact with food. It does not alter the taste, smell, or consistency of the food it touches.

Extreme Chemical Inertness

Beyond simple non-toxicity, Teflon exhibits a remarkable resistance to a vast range of chemicals.

This allows it to withstand aggressive cleaning agents and sanitizers used in both hospitals and food plants. It also remains stable when in contact with acidic foods, fats, oils, and other potentially corrosive substances.

High-Performance Functional Properties

While safety is the prerequisite, Teflon's functional properties are what make it indispensable for efficient and reliable operations.

The Signature Non-Stick Surface

Teflon's famously low coefficient of friction creates an exceptionally non-stick (or low-adhesion) surface.

In medicine, this prevents tissues from sticking to surgical tools during procedures. In food processing, it stops sticky doughs, sugars, and proteins from adhering to machinery, which reduces waste, minimizes downtime, and makes cleaning drastically easier.

Resilience to Sterilization and Temperature

Medical instruments and food equipment must be rigorously sterilized. Teflon components can easily withstand common sterilization methods, including steam autoclaving and hot water washes.

Furthermore, it maintains its integrity across a wide temperature range, performing reliably in applications involving cooking, flash-freezing, hot oils, and steam.

Durability as a Component

Teflon's unique balance of hardness and softness makes it an excellent material for mechanical parts in sensitive machinery.

It is frequently used for seals, gaskets, and bushings in food-grade equipment. It provides a reliable seal without requiring liquid lubricants that could contaminate the product.

Understanding the Trade-offs

No material is perfect, and objectivity requires acknowledging Teflon's limitations. Its strengths in some areas create trade-offs in others.

Lower Mechanical Strength

Compared to metals or harder plastics, Teflon is a relatively soft material. It has excellent compressive strength for seals but is not suitable for high-load structural components.

Susceptibility to Abrasion

The same properties that make Teflon non-stick also mean it can be more susceptible to scratches and mechanical wear than harder surfaces. In high-abrasion environments, its lifespan may be limited.

Temperature Ceilings

While its temperature range is wide, PTFE can begin to degrade at extremely high temperatures (generally above 500°F or 260°C), potentially releasing fumes. This is a critical design consideration for high-heat applications.

Making the Right Choice for Your Application

Leveraging Teflon effectively means aligning its distinct advantages with your primary operational goal.

- If your primary focus is patient safety and medical device integrity: Rely on its proven biocompatibility and ability to withstand rigorous sterilization cycles without degrading.

- If your primary focus is food processing efficiency and hygiene: Prioritize its FDA-compliant, non-stick surface to ensure easy cleaning, reduce product waste, and guarantee food purity.

- If your primary focus is component reliability in harsh environments: Utilize its unmatched chemical inertness and wide temperature stability for durable seals and gaskets that won't contaminate your product line.

Ultimately, Teflon is the material of choice wherever high performance cannot be allowed to compromise purity.

Summary Table:

| Key Property | Benefit in Medical/Food Applications |

|---|---|

| Chemical Inertness & Biocompatibility | Non-toxic, FDA-compliant, and safe for contact with body and food. |

| Non-Stick Surface | Prevents sticking in surgery and food processing, ensuring purity and easy cleaning. |

| High-Temperature & Sterilization Resistance | Withstands autoclaves and harsh cleaning processes without degrading. |

| Durability for Components | Ideal for creating reliable seals, gaskets, and liners in sensitive machinery. |

Leverage Teflon's Unique Advantages for Your Critical Applications

For manufacturers in the semiconductor, medical, laboratory, and industrial sectors, the right PTFE component is crucial for ensuring safety, efficiency, and product integrity. KINTEK specializes in the precision manufacturing of high-performance PTFE components—including custom seals, liners, and labware—that meet the stringent demands of your industry.

We combine material expertise with custom fabrication capabilities, from prototypes to high-volume orders, to deliver solutions that enhance your product's performance and reliability.

Ready to integrate superior PTFE components into your designs? Contact KINTEK today to discuss your specific requirements and how we can support your project's success.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications