In high-pressure sealing systems, the primary role of a Teflon backup ring is to provide mechanical support to a softer, primary seal like an O-ring. It is not a seal itself, but a crucial component that prevents the O-ring from being physically damaged and forced out of its groove when subjected to high pressure or temperature.

The core function of a Teflon backup ring is to prevent seal extrusion. It accomplishes this by closing the clearance gap between system components, allowing a softer O-ring to maintain its integrity under forces that would otherwise cause it to fail.

The Core Problem: O-Ring Extrusion

To understand the value of a backup ring, you must first understand the primary failure mode it prevents: extrusion.

What Causes Extrusion?

An O-ring seals by deforming into a groove and pressing against the mating surfaces. High system pressure forces the O-ring to one side of the groove.

If the clearance gap (the small space between the moving and stationary parts) is too large, this pressure will squeeze the soft rubber of the O-ring into that gap.

The Consequences of Failure

This process is often described as "nibbling," as small pieces of the O-ring are progressively sheared off. The result is rapid seal degradation, loss of sealing pressure, catastrophic leaks, and ultimately, system failure.

How Teflon Backup Rings Provide the Solution

A backup ring is a simple, rigid ring that works in tandem with the O-ring to create a more robust sealing assembly.

The Principle of Gap Reduction

The backup ring is installed on the low-pressure side of the O-ring. When pressure is applied, it pushes the O-ring, which in turn pushes the backup ring against the component wall.

Because the Teflon ring is made of a much harder material than the O-ring, it cannot be squeezed into the clearance gap. It effectively bridges the gap, providing a solid barrier and removing the path for extrusion.

Why Teflon (PTFE) is Ideal

Teflon, or Polytetrafluoroethylene (PTFE), is the material of choice for several key reasons. It has an extremely low coefficient of friction, which is critical in dynamic applications to reduce drag and heat buildup.

Furthermore, PTFE is almost universally chemically inert and operates across a very wide temperature range, making it suitable for nearly any hydraulic or pneumatic fluid.

Configuration for Different Systems

In a single-acting system, where pressure is only applied from one direction, a single backup ring is used.

In a double-acting system, like a hydraulic cylinder that moves in two directions, two backup rings are installed, one on each side of the O-ring, to prevent extrusion regardless of the direction of pressure.

Understanding the Design Considerations

While highly effective, backup rings are not a universal fix. Their successful implementation depends on proper design and understanding their limitations.

Sizing is Critical

A backup ring must be sized correctly for the groove it occupies. If it is too loose, it will not properly close the clearance gap. If it is too tight, it can make installation difficult and may not sit correctly.

Installation Matters

Backup rings are often split (scarf-cut) or contoured to aid in installation. It is critical to avoid damaging the ring or the O-ring during assembly, as even a small nick can create a leak path.

Not a Substitute for Proper Tolerances

While backup rings can compensate for larger-than-ideal clearance gaps, they are not a substitute for good mechanical design. Relying on them to fix major tolerance issues is poor practice and can lead to other failures.

Making the Right Choice for Your Application

Specifying a backup ring is a strategic decision based on the operational demands of the system.

- If your primary focus is high-pressure performance (>1500 PSI): A Teflon backup ring is essentially a mandatory component to ensure seal longevity and prevent extrusion.

- If your primary focus is system reliability: Adding a backup ring is a low-cost insurance policy that significantly extends the service life of the O-ring, reducing maintenance and downtime.

- If you are dealing with existing hardware with large clearances: A backup ring is often the most practical and cost-effective solution for creating a reliable seal without re-machining components.

Ultimately, integrating a Teflon backup ring is a hallmark of robust engineering, transforming a standard O-ring into a high-performance sealing solution.

Summary Table:

| Function | Benefit | Key Material (PTFE) |

|---|---|---|

| Prevents O-ring extrusion into gaps | Extends seal life, prevents leaks | Extremely low friction |

| Provides mechanical support | Enables higher pressure operation (>1500 PSI) | Chemically inert |

| Bridges clearance gaps | Increases system reliability, reduces downtime | Wide temperature range |

Need a reliable sealing solution for high-pressure applications?

KINTEK specializes in manufacturing precision PTFE components, including custom backup rings, seals, and liners. We help semiconductor, medical, laboratory, and industrial equipment manufacturers solve complex sealing challenges, from prototypes to high-volume production.

Contact our experts today to discuss how our custom PTFE solutions can enhance your system's performance and reliability.

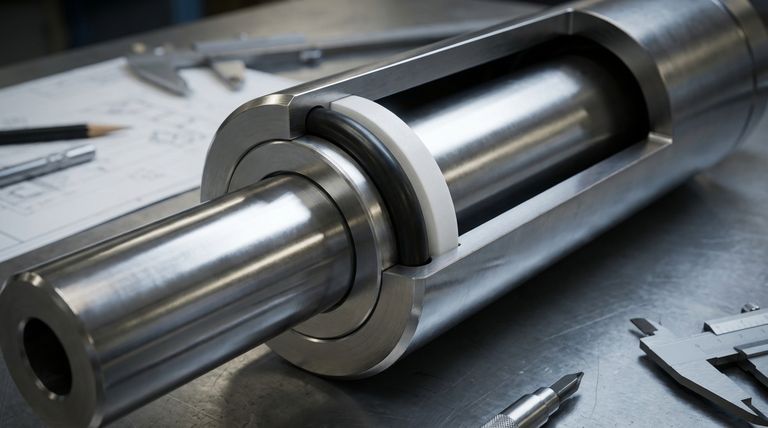

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications