In short, treating graphite packings with Polytetrafluoroethylene (PTFE) adds significant advantages by combining the inherent strengths of both materials. This treatment primarily enhances the packing's performance by drastically reducing friction, improving its chemical resistance, and preventing the graphite particles from contaminating the process fluid.

The core benefit is synergy: you are adding the near-universal chemical inertness and exceptionally low friction of PTFE to the superior self-lubrication and thermal conductivity of graphite. This creates a more durable, stable, and cleaner-running packing for a wide range of industrial applications.

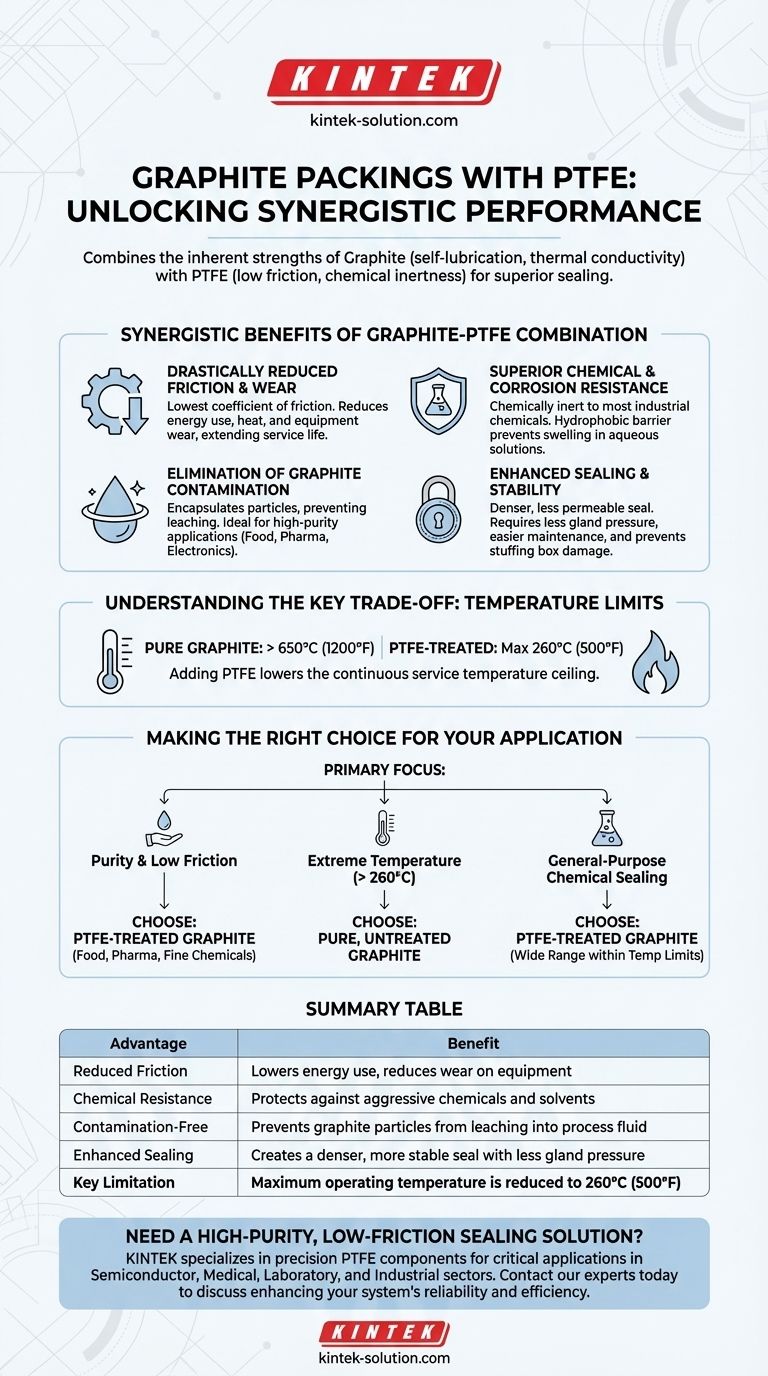

The Synergistic Benefits of a Graphite-PTFE Combination

When evaluating packing materials, it's essential to understand how individual components contribute to the final product's performance. The addition of a PTFE treatment to graphite is not merely an additive; it fundamentally changes the packing's operational characteristics.

Drastically Reduced Friction and Wear

PTFE is renowned for having the lowest coefficient of friction of any known solid material.

When used as a treatment, it coats the graphite fibers, acting as an exceptional surface lubricant. This significantly reduces the friction between the packing and the moving component, such as a pump shaft or valve stem.

This reduction in friction leads to lower operational energy requirements, less heat generation, and a dramatic decrease in wear on expensive equipment components, extending their service life.

Superior Chemical and Corrosion Resistance

Graphite offers good chemical resistance, but PTFE takes it to another level. PTFE is chemically inert to almost all industrial chemicals and solvents.

By impregnating the graphite packing, the PTFE creates a protective barrier. This makes the packing suitable for use in highly aggressive or corrosive services where untreated graphite might fail.

Furthermore, PTFE is hydrophobic, meaning it repels water. This prevents the packing from swelling in humid conditions or aqueous solutions, ensuring dimensional stability and consistent sealing performance over time.

Elimination of Graphite Contamination

A common issue with standard graphite packings is the migration of fine graphite particles into the process fluid. This "blacking" is unacceptable in industries that demand high purity.

The PTFE treatment effectively encapsulates the graphite particles, preventing them from leaching out. This makes PTFE-treated graphite packings an ideal choice for applications in the food, pharmaceutical, and electronics industries where product purity is non-negotiable.

Enhanced Sealing and Stability

The PTFE dispersion fills the microscopic voids within the braided graphite packing, creating a denser and less permeable final product.

This results in a more stable seal that requires less gland pressure to activate, further reducing friction and wear. The inherent non-adhesive, or "non-stick," property of PTFE also ensures easier removal and replacement during maintenance, preventing damage to the stuffing box.

Understanding the Key Trade-off: Temperature Limits

While the benefits are significant, it is critical to recognize the primary limitation introduced by the PTFE treatment: a reduced maximum operating temperature.

The Impact of PTFE on Thermal Rating

Pure graphite packings are known for their exceptional performance at extremely high temperatures, often exceeding 650°C (1200°F) in non-oxidizing environments.

PTFE, however, has a much lower continuous service temperature limit, typically around 260°C (500°F).

Adding PTFE to graphite packing imposes this lower temperature ceiling on the composite material. Attempting to use a PTFE-treated packing above this limit will cause the PTFE to degrade, compromising the seal and negating its benefits.

Making the Right Choice for Your Application

Selecting the correct packing requires matching the material's properties to the specific demands of your system.

- If your primary focus is purity and low friction: PTFE-treated graphite is the superior choice for applications in food, pharma, or fine chemicals where preventing contamination and minimizing shaft wear are critical.

- If your primary focus is extreme temperature resistance: Pure, untreated graphite packing is necessary for services that operate consistently above 260°C (500°F).

- If your primary focus is general-purpose chemical sealing: The balanced performance profile of PTFE-treated graphite provides an excellent, reliable seal for a vast range of chemical, water, and solvent applications within its temperature limits.

Ultimately, understanding the trade-off between enhanced chemical inertness and reduced temperature range empowers you to select the most reliable and cost-effective sealing solution.

Summary Table:

| Advantage | Benefit |

|---|---|

| Reduced Friction | Lowers energy use, reduces wear on equipment |

| Chemical Resistance | Protects against aggressive chemicals and solvents |

| Contamination-Free | Prevents graphite particles from leaching into process fluid |

| Enhanced Sealing | Creates a denser, more stable seal with less gland pressure |

| Key Limitation | Maximum operating temperature is reduced to 260°C (500°F) |

Need a high-purity, low-friction sealing solution for your critical application?

KINTEK specializes in manufacturing precision PTFE components, including custom seals and packings. We serve the semiconductor, medical, laboratory, and industrial sectors, delivering the exact performance characteristics you need—from prototypes to high-volume production.

Contact our experts today to discuss how our PTFE-treated graphite packings can enhance your system's reliability and efficiency.

Visual Guide

Related Products

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key features of PTFE? Unmatched Performance for Extreme Industrial Environments

- What are PTFE reducing flanges used for? Connect Pipes of Different Sizes with Superior Chemical Resistance

- How is vertical load accommodated in PTFE sliding bearings? Design for High Load & Movement

- What are the benefits of graphite-filled PTFE? Superior Self-Lubrication for Demanding Seals & Bearings

- How often should PTFE butterfly valves be maintained? Optimize Your Maintenance Schedule

- What are some industrial applications of PTFE lip seals in extreme temperatures? Ensuring Reliability from Cryogenics to High Heat

- What are the most suitable PTFE grades for CNC machined parts? Achieve Optimal Performance and Durability

- What are the temperature limitations of Teflon packing? Ensure Sealing Integrity from -200°C to 260°C