At its core, adding graphite to PTFE transforms it into a high-performance material for dynamic applications by dramatically improving its self-lubricating properties. This enhancement significantly reduces friction and increases wear resistance, particularly when used against softer metal surfaces. The graphite filler gives the material its characteristic black or dark gray color.

The fundamental benefit of graphite-filled PTFE is its ability to function as a superior bearing and seal material. It solves the inherent problems of high wear rates and deformation (creep) found in unfilled PTFE, making it the preferred choice for applications involving sliding contact, especially at higher speeds or against sensitive surfaces.

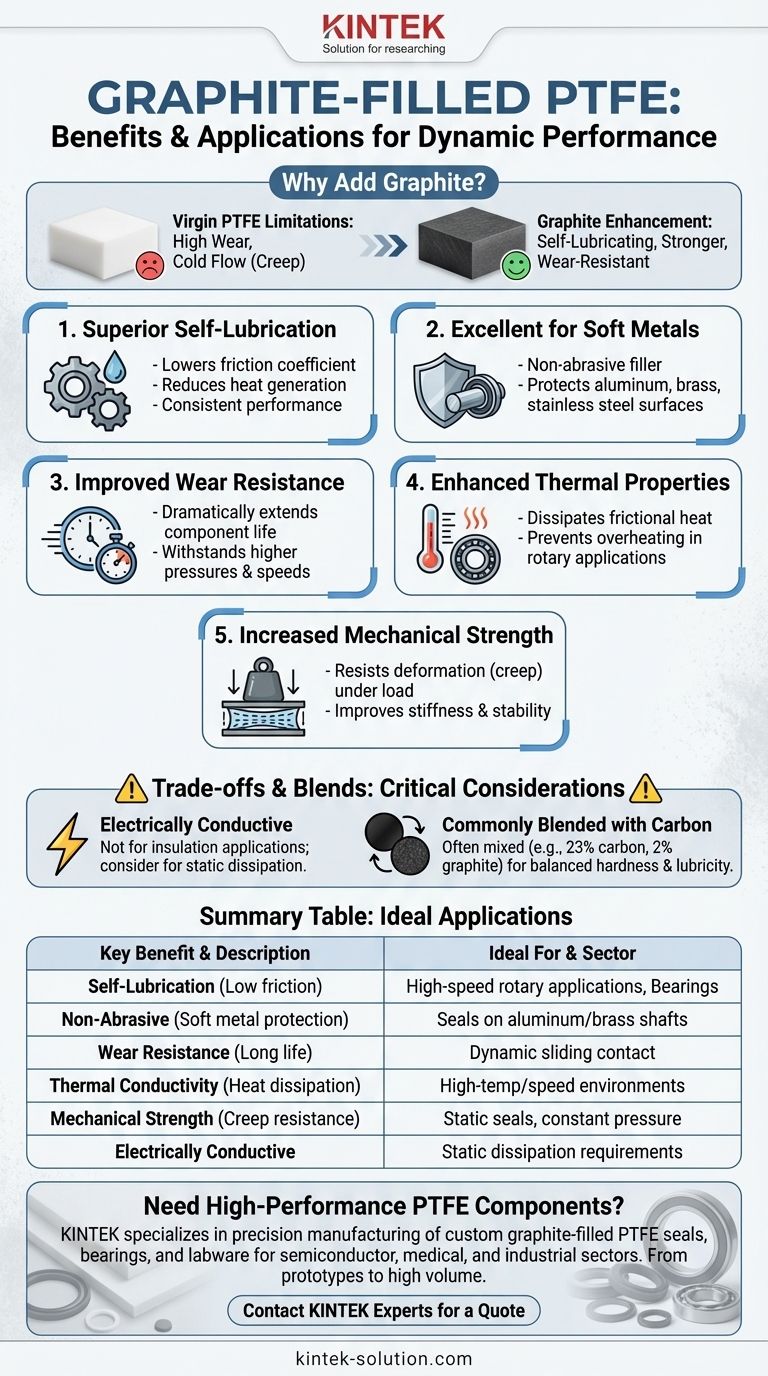

Why Add Fillers to PTFE?

The Limitations of Virgin PTFE

While prized for its extreme chemical inertness and low coefficient of friction, pure (virgin) PTFE has significant mechanical weaknesses.

Under pressure, especially in dynamic applications, it is prone to cold flow, or creep, where the material slowly deforms. It also has a relatively high rate of wear, which limits its lifespan as a bearing or seal.

How Graphite Enhances Performance

Graphite is a form of carbon with a crystalline, layered structure. These layers can easily slide over one another, making it an excellent solid lubricant.

When blended into PTFE (typically at concentrations of 5% to 25%), these graphite particles embed within the polymer matrix. They create a material that is not only strong but also continuously lubricates the contact surface as it wears.

Key Benefits of Graphite-Filled PTFE

Superior Self-Lubrication and Low Friction

This is the primary advantage. The graphite significantly lowers the coefficient of friction compared to virgin PTFE, reducing the energy needed for movement and minimizing heat generation.

This self-lubricating quality is consistent throughout the material's life, ensuring reliable, low-friction performance.

Excellent for Soft Metal Surfaces

Many fillers, like glass, are abrasive and can score or damage softer shafts (such as aluminum, brass, or stainless steel).

Graphite is a non-abrasive filler. Its lubricity protects softer counter-surfaces, making it an ideal choice for seals and bearings running against soft metals.

Improved Wear Resistance

By reducing friction and adding structural reinforcement, graphite dramatically improves the wear life of PTFE components.

The material can withstand higher pressures and speeds without rapid degradation, leading to longer service intervals and greater reliability.

Enhanced Thermal Properties

Graphite is thermally conductive. This property allows it to dissipate frictional heat away from the contact surface of a seal or bearing.

Better heat dissipation prevents overheating, which is a common cause of failure in high-speed rotary applications. This results in better performance at extreme temperatures and shaft speeds.

Increased Mechanical Strength

Like other fillers, graphite improves PTFE's mechanical properties. It provides additional stiffness and significantly resists deformation under load.

This reduces cold flow and makes the material less prone to extrusion, meaning it holds its shape and tolerances better under pressure.

Understanding the Trade-offs and Blends

Electrical Conductivity: A Critical Consideration

Virgin PTFE is an excellent electrical insulator. The addition of carbon in the form of graphite makes the material electrically conductive.

This is a critical factor. For any application requiring electrical insulation, graphite-filled PTFE is unsuitable and a different filler, such as glass, should be considered.

Often Blended with Carbon

Graphite is frequently used in combination with other fillers, most commonly amorphous carbon. A typical blend for rotary shaft seals is 23% carbon and 2% graphite.

In this formulation, the carbon provides the primary benefits of hardness and creep resistance, while the small amount of graphite adds lubricity for reduced friction and break-in wear.

Making the Right Choice for Your Application

- If your primary focus is sealing against a soft shaft (e.g., aluminum): Graphite-filled PTFE is an excellent choice due to its non-abrasive, self-lubricating properties.

- If your primary focus is high-speed rotary applications: The enhanced thermal conductivity of a graphite blend helps dissipate heat, improving seal life and performance.

- If your primary focus is reducing creep in a static seal: A carbon-graphite blend provides the necessary mechanical stability that virgin PTFE lacks.

- If your primary focus is electrical insulation: You must avoid graphite-filled PTFE and instead consider virgin PTFE or a formulation with a non-conductive filler.

By understanding these properties, you can confidently specify graphite-filled PTFE for demanding applications where reducing friction and wear is paramount.

Summary Table:

| Key Benefit | Description | Ideal For |

|---|---|---|

| Superior Self-Lubrication | Significantly lowers friction and reduces heat generation. | High-speed rotary applications, bearings. |

| Non-Abrasive to Soft Metals | Protects surfaces like aluminum and brass from scoring. | Seals and bearings on soft shafts. |

| Enhanced Wear Resistance | Dramatically extends component life under pressure. | Dynamic applications with sliding contact. |

| Improved Thermal Conductivity | Dissipates frictional heat to prevent failure. | High-temperature and high-speed environments. |

| Increased Stiffness & Creep Resistance | Resists deformation under load better than virgin PTFE. | Static seals and components under constant pressure. |

| Electrically Conductive | Provides electrical conductivity (unlike insulating virgin PTFE). | Applications requiring static dissipation or conductivity. |

Need a High-Performance PTFE Component?

Graphite-filled PTFE is a specialized material, and getting the formulation and fabrication right is critical for your application's success. KINTEK specializes in the precision manufacturing of PTFE components, including custom graphite-filled formulations for seals, bearings, and labware.

We serve the semiconductor, medical, laboratory, and industrial sectors, providing everything from prototypes to high-volume orders.

Let us help you solve your toughest sealing and bearing challenges. Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments