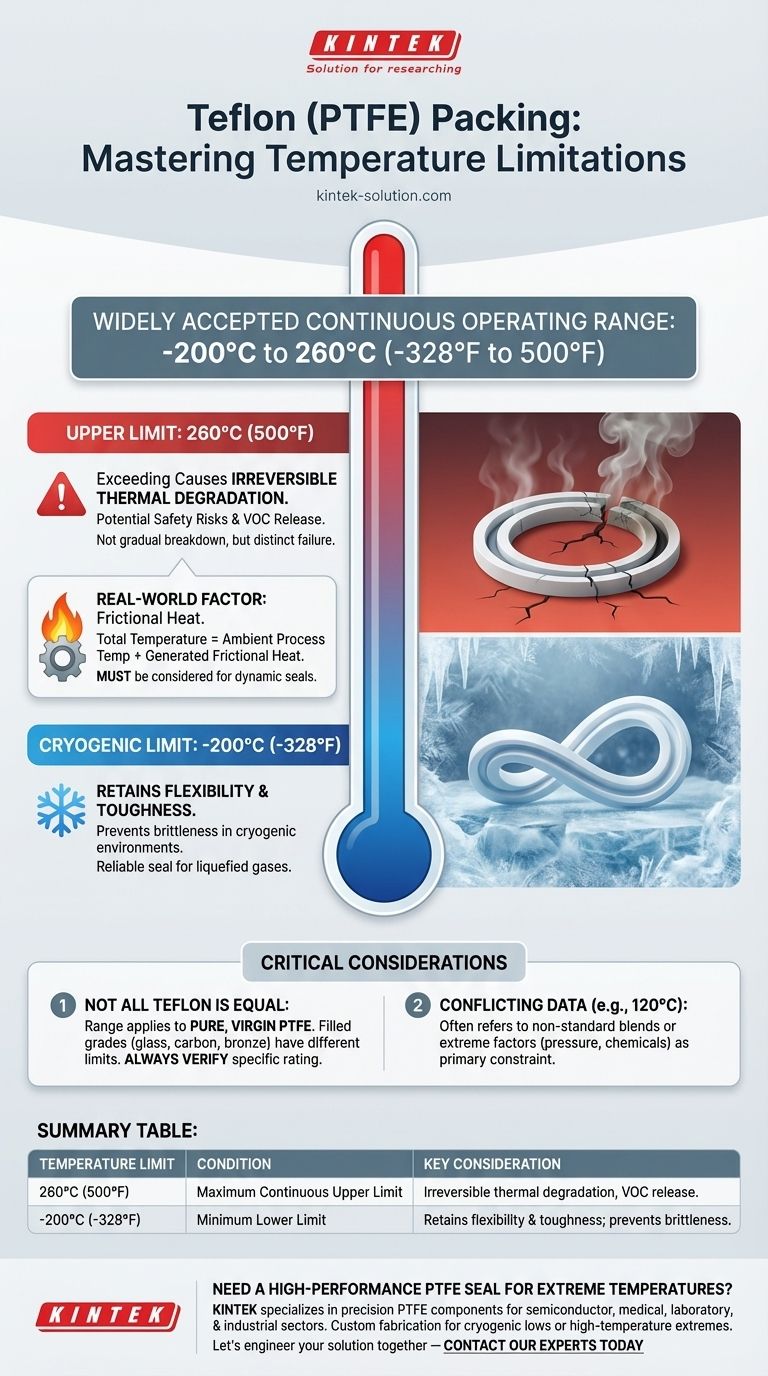

In short, the widely accepted continuous operating temperature for Teflon (PTFE) packing is from -200°C to 260°C (-328°F to 500°F). While it offers exceptional thermal stability within this range, exceeding the upper limit causes irreversible material degradation and poses potential safety risks. Understanding this threshold is critical for ensuring the integrity and reliability of any sealed system.

The core challenge is not just knowing a temperature number, but understanding the consequences of approaching or exceeding it. While Teflon has an impressively wide operating range, its failure at high temperatures is not gradual—it is a distinct breakdown that can compromise your equipment and create safety hazards.

The Upper Temperature Limit: More Than Just a Number

The maximum temperature rating for Teflon packing is the most critical factor for most industrial applications. This limit is defined by the point at which the material begins to lose its fundamental properties.

The 260°C (500°F) Threshold

This figure represents the maximum temperature at which pure PTFE can operate continuously without significant degradation. Below this point, it maintains its exceptional chemical resistance, low-friction surface, and structural integrity.

This makes it a default choice for high-heat equipment, including industrial ovens, automotive engines, and various manufacturing processes.

What Happens Above 260°C?

When temperatures exceed this limit, Teflon does not melt like a traditional plastic. Instead, it undergoes thermal degradation.

The material begins to break down, losing its structural stability and sealing capability. More importantly, this process can release volatile organic compounds (VOCs), which can pose health and environmental concerns if not properly managed.

Performance in Cryogenic Conditions

While the upper limit gets the most attention, Teflon's performance at extremely low temperatures is just as remarkable and essential for certain industries.

The -200°C (-328°F) Lower Limit

PTFE is a premier choice for cryogenic applications. It can reliably operate at temperatures as low as -200°C (-328°F).

Why Teflon Excels at Low Temperatures

Unlike rubber and many other polymers that become extremely brittle and crack at low temperatures, PTFE retains a useful degree of flexibility and toughness. This allows it to maintain a reliable seal on equipment handling liquefied gases or operating in deep-freeze environments.

Understanding the Trade-offs and Considerations

A material's datasheet temperature is only part of the story. Real-world conditions introduce variables that must be considered to ensure reliability and safety.

Frictional Heat Adds to the Load

The 260°C limit applies to the material itself. In a dynamic application like a pump or a rotary shaft seal, friction from pressure and speed generates significant additional heat directly at the point of contact.

You must calculate the total expected temperature—the ambient process temperature plus the generated frictional heat—to ensure it remains safely below the 260°C threshold.

Not All Teflon Is Created Equal

The -200°C to 260°C range applies specifically to pure, virgin PTFE. Many packings use filled grades of PTFE to enhance other properties.

Fillers like glass, carbon, or bronze can improve wear resistance and reduce creep (the tendency to deform under load). However, these additives can sometimes alter the temperature limits or chemical compatibility of the final product. Always verify the specific rating for the exact packing material you are using.

A Note on Conflicting Data

You may occasionally see lower temperature limits cited, such as 120°C. These figures almost always refer to a specific, non-standard blend or an application where other factors (like extreme pressure or aggressive chemical combinations) are the primary constraint, not the temperature itself. For standard PTFE, 260°C remains the accepted upper limit.

Making the Right Choice for Your Application

Selecting the correct packing requires matching the material's properties to the system's operational demands.

- If your primary focus is high-temperature stability: Confirm your total operational temperature, including any heat generated by friction, remains safely below the 260°C (500°F) threshold for PTFE.

- If your primary focus is cryogenic performance: Teflon (PTFE) is an excellent choice, as it retains its sealing properties and avoids brittleness down to -200°C (-328°F).

- If you are operating near the temperature limits: Consider using filled PTFE grades designed for enhanced performance, but always verify the specific temperature ratings from the manufacturer for that particular product.

By understanding both the absolute limits and the real-world factors that influence performance, you can confidently select the right material and ensure long-term operational reliability.

Summary Table:

| Temperature Limit | Condition | Key Consideration |

|---|---|---|

| 260°C (500°F) | Maximum Continuous Upper Limit | Exceeding this causes irreversible thermal degradation and potential VOC release. |

| -200°C (-328°F) | Minimum Lower Limit | PTFE retains flexibility and toughness, preventing brittleness in cryogenic environments. |

Need a high-performance PTFE seal for extreme temperatures?

At KINTEK, we specialize in manufacturing precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Whether your application operates at cryogenic lows or high-temperature extremes, our custom fabrication ensures your sealing solutions are reliable, durable, and perfectly suited to your specific thermal and chemical environment.

Let's engineer your solution together—contact our experts today for a custom quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications