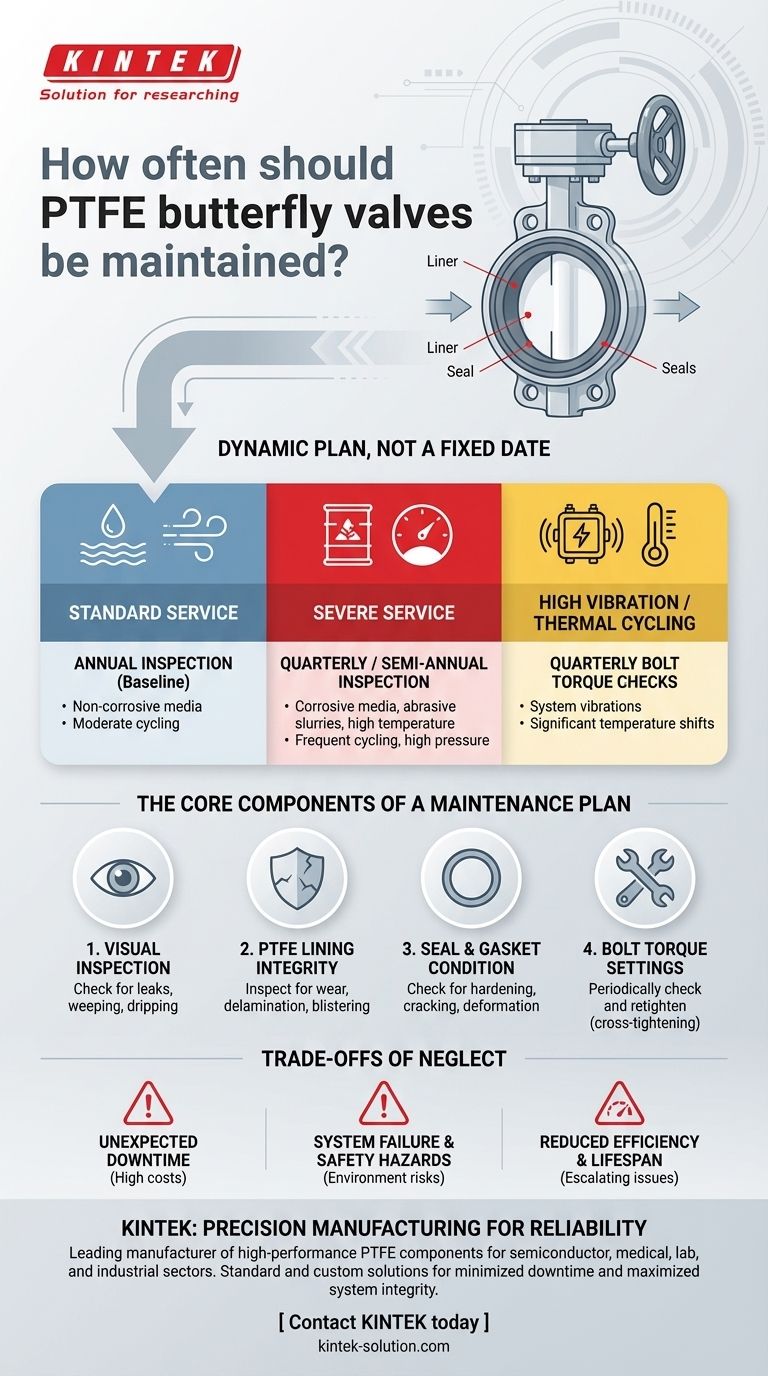

While there is no universal schedule, a PTFE butterfly valve in standard service should undergo a comprehensive inspection at least once a year. For valves operating under severe conditions—such as handling corrosive media, experiencing frequent cycling, or high pressure—inspections should be conducted more frequently, potentially on a quarterly or semi-annual basis.

The ideal maintenance schedule for a PTFE butterfly valve is not a fixed date on a calendar, but a dynamic plan based on its specific operating conditions. Proactive inspection is the key to preventing unexpected downtime and ensuring long-term system reliability.

Why Maintenance Frequency Varies

The "once-a-year" guideline is merely a starting point. The optimal frequency is dictated entirely by the valve's working environment and the demands placed upon it.

The Impact of Application and Media

The nature of the fluid passing through the valve is the primary factor. Highly corrosive chemicals, abrasive slurries, or high-temperature media will accelerate the wear on the PTFE lining and seals, necessitating more frequent checks.

The Role of Operational Demands

A valve that is cycled (opened and closed) hundreds of times a day will experience significantly more mechanical stress than one that is only operated occasionally. High-pressure systems also put greater strain on seals and gaskets.

The Influence of the External Environment

External factors like system vibrations or significant thermal cycling (shifts from hot to cold) can cause bolts to loosen over time. This compromises the integrity of the valve's seal and requires more frequent monitoring.

The Core Components of a Maintenance Plan

Effective maintenance is more than just a date; it's a systematic process of inspection and verification. A thorough check should cover several critical points.

Visual Inspection for Leaks

The most basic and essential check is a visual scan for any signs of leaks around the valve stem or flange connections. Any evidence of weeping or dripping is an immediate indicator that the seals or gaskets require attention.

Checking the PTFE Lining Integrity

The PTFE liner is the valve's primary defense against corrosion. During a shutdown, inspect the liner for any signs of wear, delamination, blistering, or physical damage. A compromised liner can lead to rapid valve failure.

Verifying Seal and Gasket Condition

Seals and gaskets are typically the first components to degrade. They should be inspected for signs of hardening, cracking, or deformation. It is often wise to replace them proactively based on the manufacturer's recommendations rather than waiting for a failure.

Validating Bolt Torque Settings

Vibrations and thermal expansion can cause flange bolts to lose their specified torque. Periodically checking and retightening bolts using a cross-tightening sequence is critical for maintaining a secure, leak-proof seal. This is especially important after initial installation and any major maintenance event.

Understanding the Trade-offs of Neglect

Skipping or delaying maintenance is rarely a cost-saving measure. The potential consequences of valve failure almost always outweigh the investment in a proactive maintenance program.

The High Cost of Unexpected Downtime

A failed valve can bring an entire process to a halt. The cost of lost production from unplanned downtime is often orders of magnitude greater than the cost of a regular maintenance inspection.

The Risk of System Failure and Safety Hazards

A leaking valve is more than an operational issue; it can be a serious safety and environmental hazard, especially when dealing with hazardous chemicals. Failure can also cause damage to other expensive equipment within the system.

Reduced Efficiency and Lifespan

A poorly maintained valve may not seal perfectly, leading to internal leaks that reduce system efficiency. Neglecting minor issues allows them to escalate, ultimately shortening the valve's operational lifespan.

Creating a Practical Maintenance Schedule

Use your valve's operating conditions as the guide to establish a reliable maintenance frequency.

- If your valve is in standard service (non-corrosive media, moderate cycling): Begin with a comprehensive annual inspection and use the findings to adjust future frequency.

- If your valve is in severe service (corrosive fluids, high pressure/temperature): Start with quarterly inspections to establish a baseline for wear and determine a sustainable long-term schedule.

- If your system experiences significant vibration or thermal cycling: Implement semi-annual or quarterly bolt torque checks in addition to your standard operational inspections.

Ultimately, treating valve maintenance as a proactive strategy rather than a reactive task is the best way to ensure operational integrity and safety.

Summary Table:

| Service Condition | Recommended Inspection Frequency | Key Factors |

|---|---|---|

| Standard Service | Annually | Non-corrosive media, moderate cycling |

| Severe Service | Quarterly or Semi-Annually | Corrosive/abrasive media, high pressure/temperature, frequent cycling |

| High Vibration/Thermal Cycling | Quarterly (Bolt Torque Checks) | System vibrations, significant temperature shifts |

Ensure your PTFE components operate reliably and safely with KINTEK's precision manufacturing.

As a leading manufacturer of high-performance PTFE components—including seals, liners, labware, and custom fabrications—KINTEK serves the semiconductor, medical, laboratory, and industrial sectors. We understand the critical role that components like PTFE butterfly valves play in your operations.

Whether you need standard parts or custom solutions from prototypes to high-volume orders, our commitment to precision and durability helps you minimize downtime and maximize system integrity.

Contact KINTEK today to discuss your specific requirements and discover how our PTFE expertise can benefit your application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What industries and applications commonly use piston seals? From Heavy Construction to Medical Devices

- What are the advantages of PTFE sliding rubber bearings? Achieve Low-Friction, Maintenance-Free Structural Movement

- What makes PTFE compensators suitable for handling aggressive chemicals? Unmatched Chemical Inertness for Your System

- What are the advantages of using PTFE lined ball valves in corrosive environments? Achieve Superior Corrosion Resistance

- What capabilities exist for manufacturing PTFE with different methods? A Guide to Polymerization and Fabrication

- How can deformation of PTFE during machining be minimized? Master Precision with Sharp Tools & Thermal Control

- What are the medical uses of Teflon? Essential for Safe, Non-Reactive Medical Devices

- What are alternatives to Teflon sheets for heat press? Parchment Paper vs. Silicone vs. Teflon