In short, Polytetrafluoroethylene (PTFE) diaphragms are used in nearly every industry where handling aggressive chemicals, ensuring absolute purity, or achieving long-term mechanical reliability is critical. They are foundational components in chemical processing, pharmaceuticals, bioprocessing, semiconductor manufacturing, and food and beverage production, among many others.

The widespread adoption of PTFE diaphragms is not about the industries themselves, but about the problems they solve. PTFE's unique combination of near-total chemical inertness, high-purity, and thermal stability makes it the default choice for containing and controlling substances that would destroy or be contaminated by other materials.

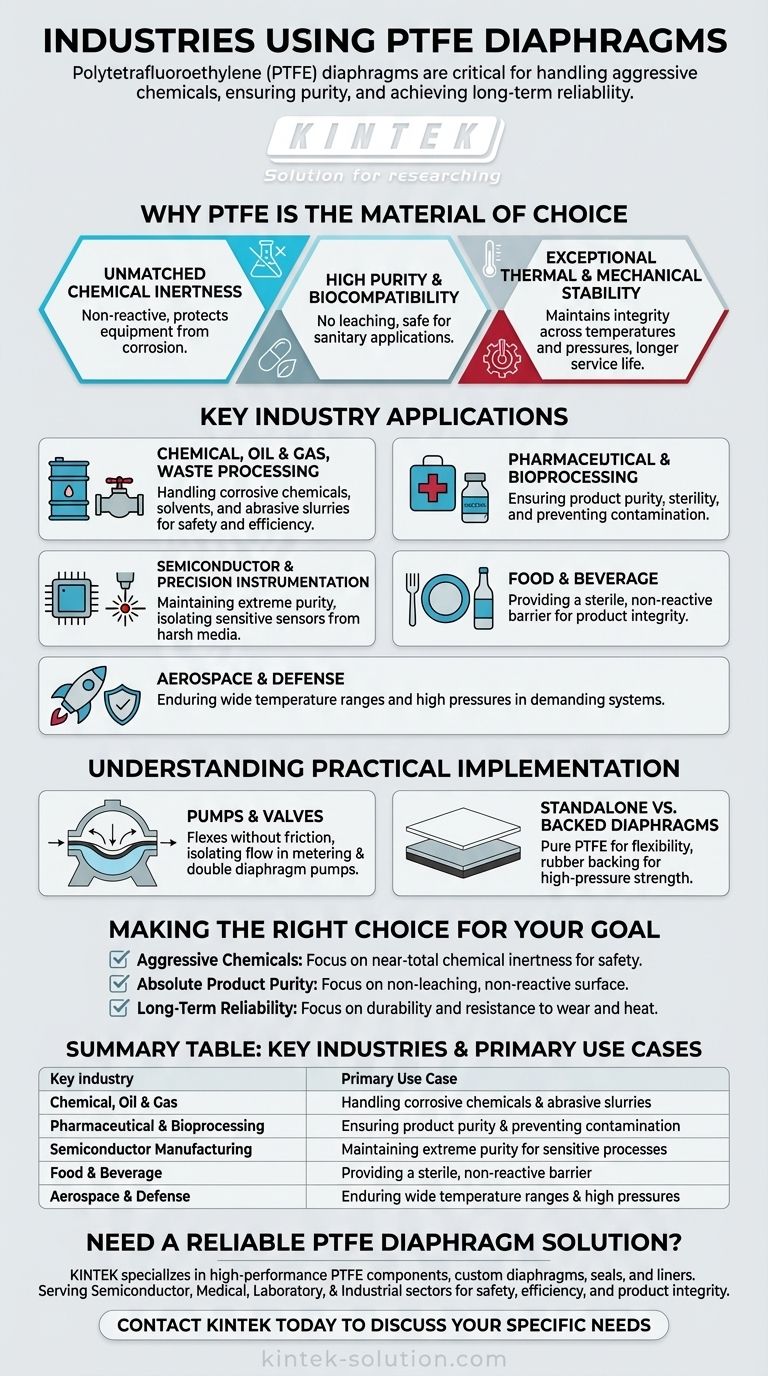

Why PTFE is the Material of Choice

The value of a PTFE diaphragm comes from its fundamental material properties. These characteristics make it uniquely suited for the most demanding operational environments.

Unmatched Chemical Inertness

PTFE is non-reactive with the vast majority of industrial chemicals, even at elevated temperatures. This makes it an essential barrier material in applications involving highly corrosive or aggressive substances.

It prevents the diaphragm itself from degrading and protects the surrounding equipment from damage.

High Purity and Biocompatibility

The material is inherently pure and does not leach contaminants into the media it contacts. This is a non-negotiable requirement in industries where even trace impurities can ruin a product batch or compromise safety.

Its biocompatibility ensures it is safe for use in sanitary applications, from food processing to medical device manufacturing.

Exceptional Thermal and Mechanical Stability

PTFE diaphragms maintain their integrity and flexibility across a wide range of temperatures and pressures. This stability is critical in aerospace, defense, and high-demand industrial pumping systems.

This durability translates directly to a longer service life, reducing downtime and maintenance costs compared to other materials.

A Closer Look at Key Industry Applications

While the principles are universal, the specific reasons for using PTFE diaphragms become clearer when looking at individual sectors.

Chemical, Oil & Gas, and Waste Processing

In these industries, diaphragms in pumps and valves are constantly exposed to corrosive chemicals, solvents, and abrasive slurries. PTFE's ability to withstand this chemical attack ensures operational safety and efficiency.

They are the core component that allows for the safe handling of substances that would otherwise be unmanageable.

Pharmaceutical, Bioprocessing, and Food & Beverage

The primary driver here is preventing contamination. PTFE diaphragms provide a sterile, non-reactive barrier that ensures the purity and integrity of the final product, whether it's a vaccine, a biopharmaceutical, or a food ingredient.

Semiconductor and Precision Instrumentation

The manufacturing of semiconductors requires extreme purity. PTFE diaphragms are used in fluid handling systems to prevent the release of particles or ions that could cause defects in microchips.

In precision instruments, they isolate sensitive sensors from harsh media while accurately transmitting pressure.

Understanding the Practical Implementation

A PTFE diaphragm is not just a piece of material; it's an engineered component designed to function as a flexible, impermeable barrier between two chambers.

The Role in Pumps and Valves

In both metering pumps and double diaphragm pumps, the diaphragm flexes back and forth to move fluid without any rotating parts contacting the media. PTFE's low friction and durability are perfect for this constant mechanical stress.

In diaphragm valves, it acts as the sealing element that isolates the flow from the rest of the valve mechanism.

Standalone vs. Backed Diaphragms

For maximum flexibility and purity, a diaphragm can be made of pure PTFE. However, in high-pressure applications, a rubber backing is often added.

This composite design combines the chemical resistance of the PTFE "wetted" side with the strength and resilience of the rubber backing, offering a more robust solution for demanding mechanical tasks.

Making the Right Choice for Your Goal

Selecting the right material is about matching its properties to your primary operational need.

- If your primary focus is handling aggressive chemicals: PTFE's near-total chemical inertness is its most important feature, guaranteeing safety and equipment longevity.

- If your primary focus is ensuring absolute product purity: PTFE's non-leaching and non-reactive surface is critical for applications in pharmaceuticals, food, and semiconductors.

- If your primary focus is long-term reliability in a mechanical system: PTFE's durability, low friction, and resistance to high temperatures reduce wear and minimize downtime in pumps and valves.

Ultimately, PTFE diaphragms are a critical enabling technology, allowing modern industries to operate safely and effectively under conditions that would otherwise be impossible.

Summary Table:

| Key Industry | Primary Use Case |

|---|---|

| Chemical, Oil & Gas | Handling corrosive chemicals and abrasive slurries |

| Pharmaceutical & Bioprocessing | Ensuring product purity and preventing contamination |

| Semiconductor Manufacturing | Maintaining extreme purity for sensitive processes |

| Food & Beverage | Providing a sterile, non-reactive barrier |

| Aerospace & Defense | Enduring wide temperature ranges and high pressures |

Need a reliable PTFE diaphragm solution for your critical application?

KINTEK specializes in manufacturing high-performance PTFE components, including custom diaphragms, seals, and liners. Our expertise in precision production ensures you get a component that perfectly matches your requirements for chemical inertness, purity, and mechanical reliability—whether you need a prototype or a high-volume order.

We serve the semiconductor, medical, laboratory, and industrial sectors by delivering components that enhance safety, efficiency, and product integrity.

Contact KINTEK today to discuss your specific needs and discover how our PTFE solutions can benefit your operation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- In which industries are PTFE lined ball valves commonly used? Master Corrosive & High-Purity Fluid Control

- What are the benefits of using a PTFE coating thrust washer in a fishing reel? Smoother Drag, Longer Reel Life

- What are the minimum and maximum sizes for machining PTFE parts? Design for Success with No Universal Limits

- What chemical solvents can be used to clean Teflon residue? The Safer, More Effective Alternatives

- What advancements are being made in recycling Teflon scrap? From Micronization to Upcycling

- How does mechanical stress influence the choice of PTFE packing? Select the Right Construction for Dynamic Seals

- What is the thermal shock method for cleaning Teflon residue? Safely Remove Stubborn PTFE Buildup

- How do spring-energized PTFE seals contribute to energy efficiency? Minimize Friction and Reduce Energy Waste