The thermal shock method is a cleaning technique that uses rapid, extreme temperature changes to break the bond between Teflon residue and metal surfaces. By cooling the component with a cryogenic agent like liquid nitrogen and then rapidly heating it, the different rates of contraction and expansion between the Teflon and the metal cause the stubborn residue to crack and loosen, making it easier to remove mechanically.

This method leverages the fundamental physics of thermal expansion to fracture hardened polymer residue. However, its effectiveness comes with a significant risk of damaging the underlying equipment if not performed with extreme care.

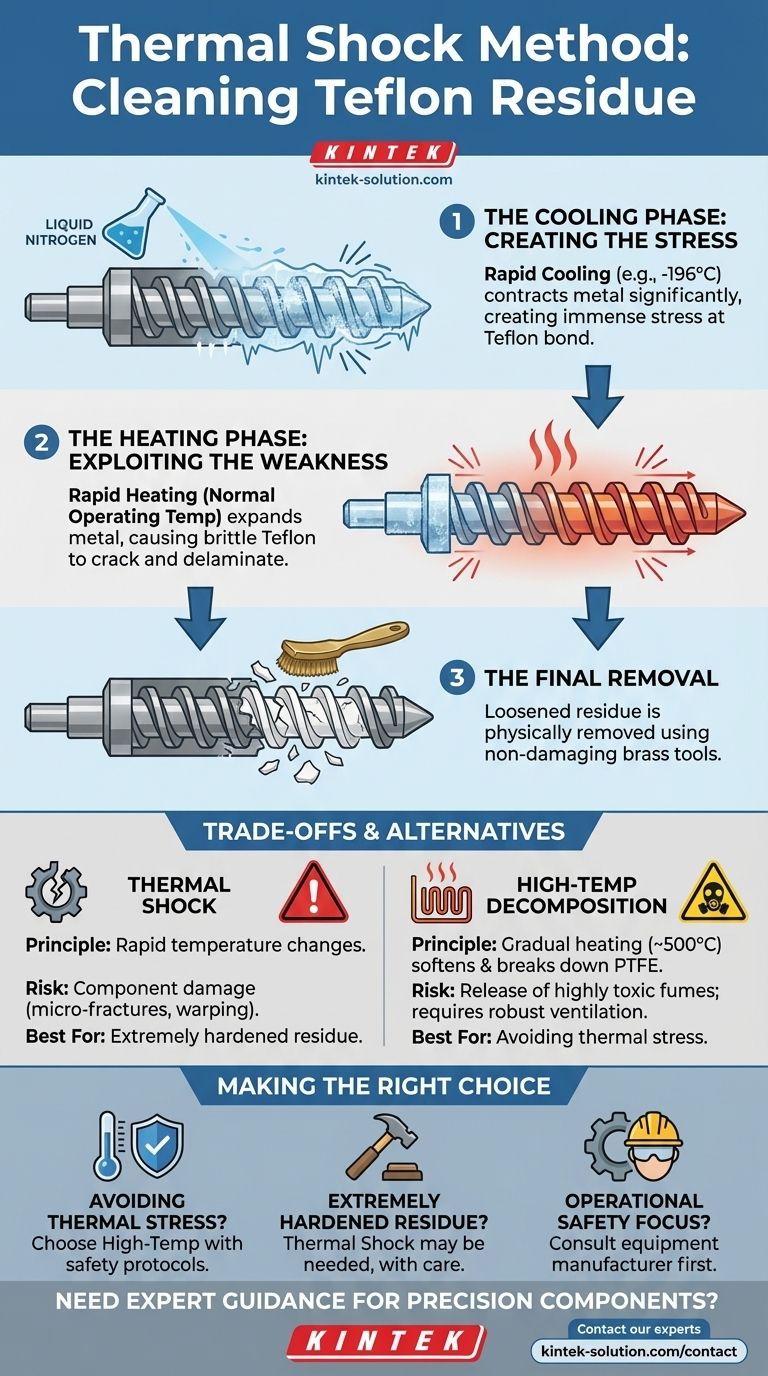

How the Thermal Shock Method Works

The entire process is based on the principle that different materials expand and contract at different rates when their temperature changes. This difference in thermal expansion coefficients between steel and Teflon is what makes the method effective.

The Cooling Phase: Creating the Stress

First, the component, such as an extruder screw or barrel, is rapidly cooled to a very low temperature.

This is typically achieved using liquid nitrogen or a commercial freeze spray. The metal component shrinks significantly, while the adhered Teflon residue contracts at a different, slower rate, creating immense stress at the bond between the two materials.

The Heating Phase: Exploiting the Weakness

Next, the component is heated back to its normal operating temperature.

As the metal rapidly expands, it moves against the still-brittle and cold Teflon. This rapid expansion exploits the stress created during the cooling phase, causing the Teflon residue to crack, fracture, or delaminate from the metal surface.

The Final Removal

Once the thermal shock has loosened the residue, it can be physically removed.

It is critical to use tools that will not damage the precision surface of the component. Brass brushes, brass scrapers, or other soft, non-metallic tools are used to scrape away the now-brittle Teflon flakes.

Understanding the Trade-offs and Alternatives

While powerful, thermal shock is an aggressive technique that is not suitable for all situations. It's crucial to weigh the benefits against the potential risks to both personnel and equipment.

Risk of Equipment Damage

The primary risk is damage to the component itself. The extreme and rapid temperature cycling can induce micro-fractures, warping, or other metallurgical damage in precision-machined parts, potentially compromising their integrity and performance.

An Alternative: High-Temperature Decomposition

An alternative approach is to gradually heat the component to a high temperature, around 500°C (932°F).

This method doesn't rely on shock but works by softening and thermally breaking down the Teflon. Once softened, the residue can be scraped away using the same non-damaging brass or non-metallic tools.

Critical Safety Warning for the High-Temp Method

The high-temperature method carries a severe health risk. When heated to such temperatures, Teflon can release highly toxic fluorinated compounds into the air.

This method must only be performed in an area with robust, industrial-grade ventilation. Appropriate personal protective equipment (PPE), including respiratory protection, is non-negotiable.

Making the Right Choice for Your Goal

Selecting the correct cleaning method depends entirely on your equipment, environment, and tolerance for risk.

- If your primary focus is avoiding thermal stress on critical components: The high-temperature method offers a more gradual and controlled process, but requires stringent safety protocols for ventilation.

- If your primary focus is breaking up extremely hardened residue: The thermal shock method can be more effective at fracturing tough deposits, but carries a higher risk of damaging the component.

- If your primary focus is operational safety: Always consult your equipment manufacturer's specific cleaning recommendations before attempting either of these aggressive methods.

Ultimately, choosing the right technique requires a clear understanding of the material science involved and a commitment to safe operational procedures.

Summary Table:

| Method | Key Principle | Primary Risk | Best For |

|---|---|---|---|

| Thermal Shock | Rapid cooling/heating fractures residue via different expansion rates. | Component damage (micro-fractures, warping). | Extremely hardened residue. |

| High-Temp Decomposition | Gradual heating softens & thermally breaks down PTFE. | Release of toxic fumes; requires intense ventilation. | Avoiding thermal stress on components. |

Struggling with stubborn PTFE residue on your precision components?

At KINTEK, we understand the critical balance between effective cleaning and preserving the integrity of your equipment. As specialists in high-performance PTFE components for the semiconductor, medical, and laboratory industries, we leverage our deep material science expertise to provide solutions.

Let us help you:

- Source precision-clean components designed for easy maintenance.

- Provide expert guidance on the safest and most effective cleaning protocols for your specific application.

- Fabricate custom PTFE parts that meet your exact specifications, from prototypes to high-volume orders.

Don't risk damaging valuable equipment. Contact our experts today for a consultation on your specific needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Scrapers and Shovels for Demanding Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Parts Manufacturer PTFE Cleaning Rack

- Custom PTFE Teflon Parts Manufacturer Conductive Glass Substrate Cleaning Rack

People Also Ask

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance