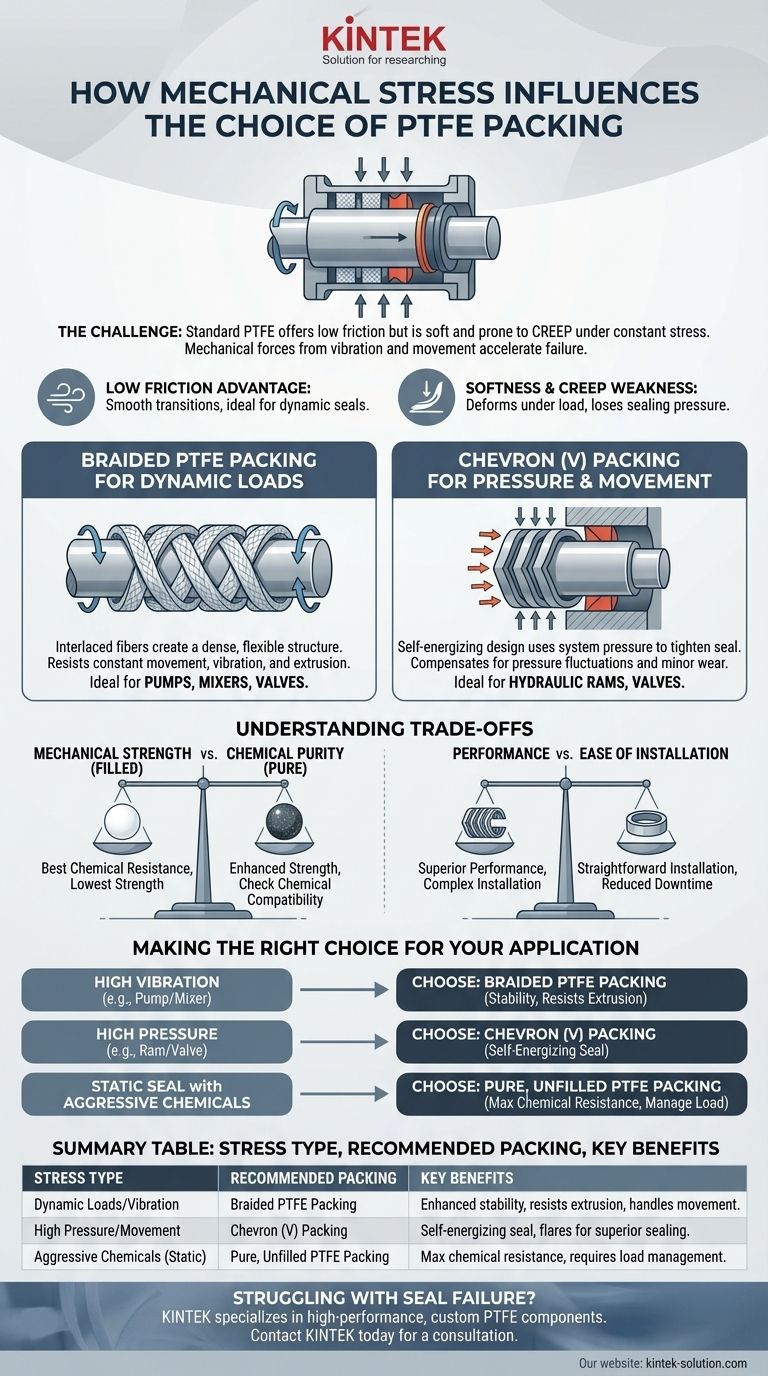

To select the right PTFE packing, you must match its construction to the mechanical forces it will face. For dynamic applications involving movement, vibration, or pressure fluctuations, standard PTFE is often insufficient; specialized designs like PTFE braided packing or PTFE chevron packing are required to ensure a durable, long-lasting seal.

The core issue is that while PTFE offers exceptional chemical resistance and low friction, it is an inherently soft material prone to deforming or "creeping" under constant stress. Mechanical forces from vibration or movement will accelerate this failure, making reinforced packing constructions essential for reliability in dynamic systems.

The Inherent Properties of PTFE

Understanding the base material is the first step in selecting the correct packing. PTFE's unique characteristics present both advantages and significant limitations when dealing with mechanical stress.

The Advantage of Low Friction

PTFE has an exceptionally low coefficient of friction. Crucially, its static and dynamic friction coefficients are nearly identical.

This property allows for smooth, stick-free transitions from a stopped to a moving state, which is highly beneficial for rotating shafts and other dynamic sealing applications.

The Challenge of Softness and Creep

Despite its benefits, PTFE is a relatively soft material with low hardness and stiffness. Its most significant mechanical weakness is its tendency to creep.

Creep is the material's inclination to slowly deform over time when subjected to a constant load. In a sealing application, this can lead to a loss of sealing pressure and eventual failure.

Low Wear Resistance

Pure PTFE also has relatively low wear resistance. In applications with frequent movement, the material can abrade away, compromising the integrity of the seal.

How Packing Construction Mitigates Stress

Manufacturers address PTFE's inherent weaknesses by designing specific packing constructions that enhance its mechanical strength and stability. The choice between them depends on the nature of the stress.

Braided PTFE Packing for Dynamic Loads

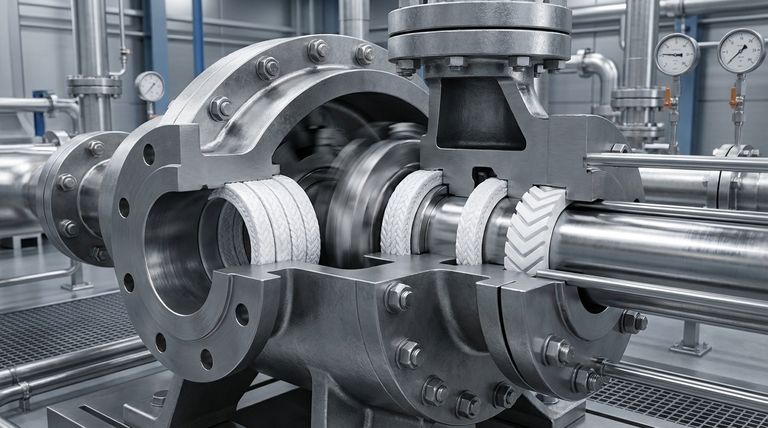

For applications involving rotating shafts or reciprocating rods—common in pumps, mixers, and valves—braided packing is the standard.

Interlacing PTFE fibers into a braid creates a dense, yet flexible, packing. This structure provides the mechanical stability needed to resist the constant movement, pressure, and vibration without quickly deforming or extruding.

Chevron Packing for Pressure and Movement

Chevron packing, also known as V-packing, consists of a set of V-shaped rings. This design is highly effective at handling both dynamic movement and high-pressure conditions.

When pressure is applied, the V-shape forces the rings to flare outwards, creating an increasingly tight seal against the shaft and housing. This self-energizing design automatically compensates for pressure fluctuations and minor wear.

Understanding the Trade-offs

Selecting the right packing involves balancing performance characteristics. Enhancing one property can sometimes compromise another.

Mechanical Strength vs. Chemical Purity

While pure PTFE offers the best chemical resistance, it has the lowest mechanical strength. To improve properties like wear resistance and compressive strength, fillers are often added.

For example, PTFE graphite packing blends PTFE with graphite. This increases thermal conductivity and mechanical robustness but must be evaluated for chemical compatibility with the specific media being sealed.

Performance vs. Ease of Installation

Complex packing systems may offer superior performance but can be more difficult to install correctly.

Some designs, like PTFE gland packing, are specifically made for straightforward installation, which can be a critical factor in reducing equipment downtime during maintenance cycles.

Making the Right Choice for Your Application

Your final decision should be guided by the primary mechanical demands of the equipment.

- If your primary focus is sealing a high-vibration pump or mixer: Choose a braided PTFE packing designed to withstand constant dynamic movement and prevent extrusion.

- If your primary focus is sealing a high-pressure hydraulic ram or valve: A chevron (V-packing) set is the superior choice, as it is engineered to use system pressure to create a more effective seal.

- If your primary focus is a static seal with aggressive chemicals: A pure, unfilled PTFE packing may be suitable, but you must account for its tendency to creep under the bolt load.

Ultimately, selecting the correct PTFE packing requires you to precisely match the material's construction to the specific mechanical stresses of your system.

Summary Table:

| Mechanical Stress Type | Recommended PTFE Packing Type | Key Benefits |

|---|---|---|

| Dynamic Loads / Vibration (e.g., pumps, mixers) | Braided PTFE Packing | Enhanced mechanical stability, resists extrusion, handles constant movement. |

| High Pressure / Movement (e.g., hydraulic rams, valves) | Chevron (V) PTFE Packing | Self-energizing seal, flares under pressure for superior sealing. |

| Aggressive Chemicals (Static) | Pure, Unfilled PTFE Packing | Maximum chemical resistance, but requires careful load management due to creep. |

Struggling with seal failure under mechanical stress? KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production ensures your PTFE packing is optimally designed to handle vibration, pressure, and dynamic loads, extending equipment life and preventing downtime. From prototypes to high-volume orders, we deliver reliable solutions.

Contact KINTEK today for a consultation on your specific application needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance