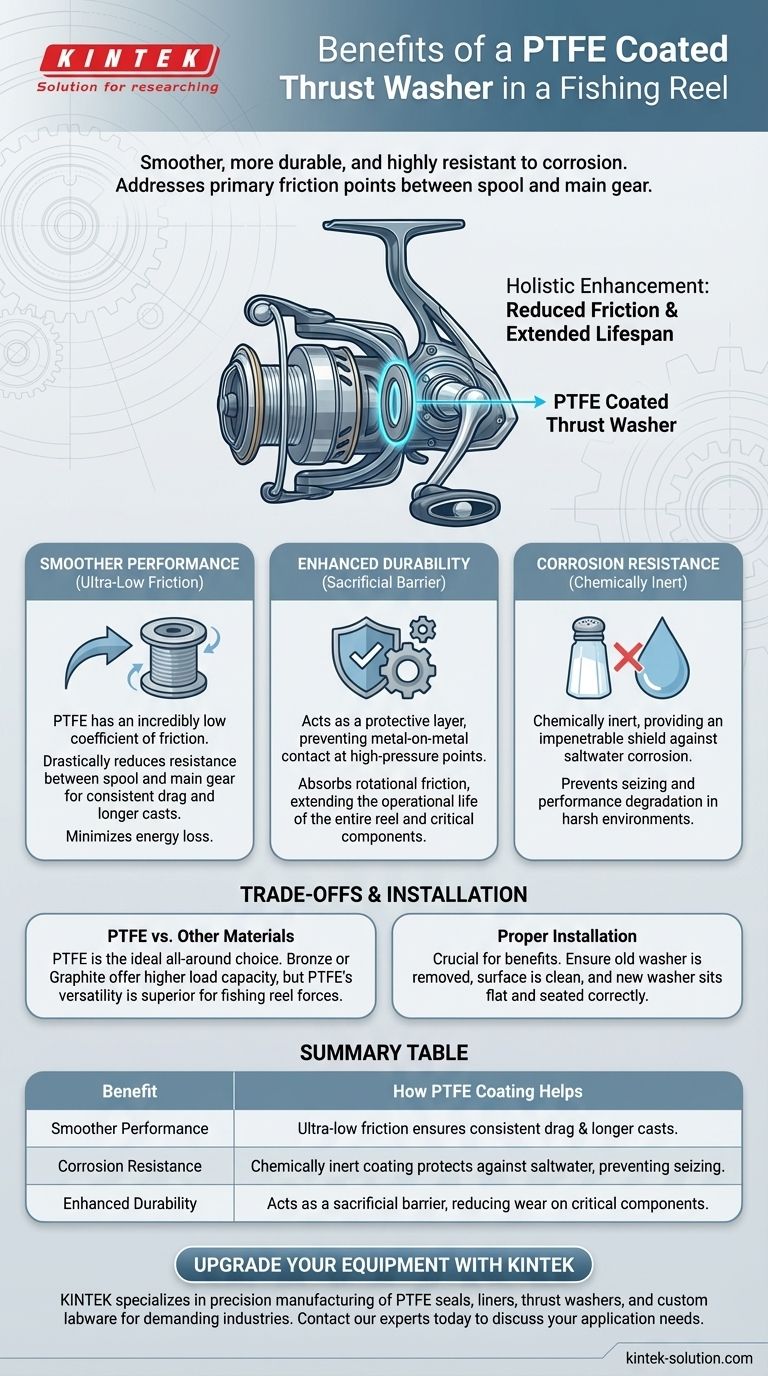

In short, a PTFE-coated thrust washer makes your fishing reel smoother, more durable, and highly resistant to corrosion. This single component upgrade directly addresses the primary points of friction and wear between the spool and the main gear, resulting in a noticeable improvement in overall performance, especially in harsh saltwater environments.

The central benefit of a PTFE-coated thrust washer is not just one specific improvement, but a holistic enhancement. It simultaneously reduces operational friction for a smoother feel while adding a durable, protective layer that extends the reel's lifespan.

Deconstructing the Performance Gains

To understand the value of this upgrade, we need to look at how the properties of PTFE (Polytetrafluoroethylene) solve common problems inside a fishing reel.

The Physics of Low Friction

A key performance metric for any mechanical system is its coefficient of friction. PTFE is renowned for having one of the lowest coefficients of any solid material.

When applied to a thrust washer, this slick surface drastically reduces the resistance between the spool and the reel's main gear. This translates directly to a smoother, more consistent drag system and can even contribute to longer casting distances by minimizing energy loss.

Enhancing Durability and Lifespan

The PTFE coating acts as a sacrificial, protective barrier. It prevents direct metal-on-metal contact at a high-pressure point within the reel.

This significantly reduces wear and tear on more critical and expensive components like the spool shaft and gear assembly. The washer itself absorbs the rotational friction, extending the operational life of the entire reel.

A Critical Defense Against Corrosion

PTFE is chemically inert, meaning it does not react with common corrosive agents like salt. This is a critical advantage for saltwater fishing.

A standard metal washer can quickly corrode and seize, degrading performance and potentially damaging the reel. The PTFE coating creates an impenetrable shield, ensuring a smooth-turning spool even after repeated exposure to saltwater.

Understanding the Trade-offs

While highly effective, it's important to see where this component fits within the broader context of reel maintenance and performance.

Is PTFE Always the Best Choice?

For the vast majority of fishing applications, PTFE is an ideal all-around choice. Its combination of low friction, durability, and corrosion resistance is unmatched.

Other materials like bronze or graphite can offer higher load-carrying capacity but are often unnecessary for the forces present in a typical fishing reel. The versatility of PTFE makes it the superior choice for this specific application.

The Importance of Proper Installation

A high-performance component only delivers benefits if it is installed correctly. A poorly seated washer can introduce wobble or fail to provide a consistent surface.

Ensure the old washer is fully removed and the spool surface is clean before placing the new PTFE-coated washer. It must sit flat and be properly seated to function as intended.

Making the Right Choice for Your Reel

Upgrading to a PTFE-coated thrust washer is a cost-effective way to achieve a tangible improvement in your reel's performance and longevity.

- If your primary focus is smoother drag and casting: The ultra-low friction coefficient of the PTFE coating will provide an immediate and noticeable improvement.

- If your primary focus is saltwater fishing: The chemical inertness of the coating offers essential protection against corrosion, making it a mandatory upgrade.

- If your primary focus is extending the life of your reel: The durable, protective layer minimizes wear on critical internal components, saving you from more costly repairs down the line.

Ultimately, this simple component protects your investment and enhances your experience on the water.

Summary Table:

| Benefit | How PTFE Coating Helps |

|---|---|

| Smoother Performance | Ultra-low friction coefficient ensures a consistent drag and longer casts. |

| Corrosion Resistance | Chemically inert coating protects against saltwater, preventing seizing. |

| Enhanced Durability | Acts as a sacrificial barrier, reducing wear on critical internal components. |

Ready to upgrade your equipment with high-performance PTFE components?

KINTEK specializes in the precision manufacturing of PTFE seals, liners, thrust washers, and custom labware. Our components are trusted in demanding industries like semiconductor, medical, and industrial manufacturing for their superior durability and chemical resistance. Whether you need a prototype or a high-volume order, we deliver solutions that enhance performance and longevity.

Contact our experts today to discuss your specific application needs and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Why are ceramic-reinforced laminates preferred in RF systems? Superior Signal Integrity & Thermal Management

- How are PTFE rotary shaft lip seals utilized in the automotive industry? Essential for High-Performance & EV Systems

- What advantages do PTFE expansion bellows offer over traditional alternatives? Achieve Unmatched Reliability in Demanding Environments

- What is a Teflon O-ring? A Guide to PTFE Seals for Extreme Chemical and Temperature Resistance

- What role do Teflon machined parts play in chemical processing equipment? Ensure Purity & Prevent Corrosion

- Are PTFE coating thrust washers suitable for all types of fishing reels? Matching Performance to Your Angling Needs

- How does a Labyrinth PTFE Seal work? Achieve Frictionless, Long-Term Reliability

- What factors affect the choice between Teflon and parchment for heat pressing? Achieve the Perfect Finish Every Time