In high-frequency RF systems, material performance is not just a detail—it is the foundation of the entire design. Ceramic-reinforced laminates are preferred because their engineered properties deliver superior electrical stability, thermal management, and mechanical reliability compared to traditional glass-weave materials, directly addressing the unique challenges of high-frequency signal propagation.

The core reason for choosing ceramic-reinforced laminates is the pursuit of consistency. By eliminating the unpredictable "weave effect" of glass fibers and providing uniform material properties, they allow RF engineers to design circuits that behave exactly as modeled, which is critical for performance at high frequencies.

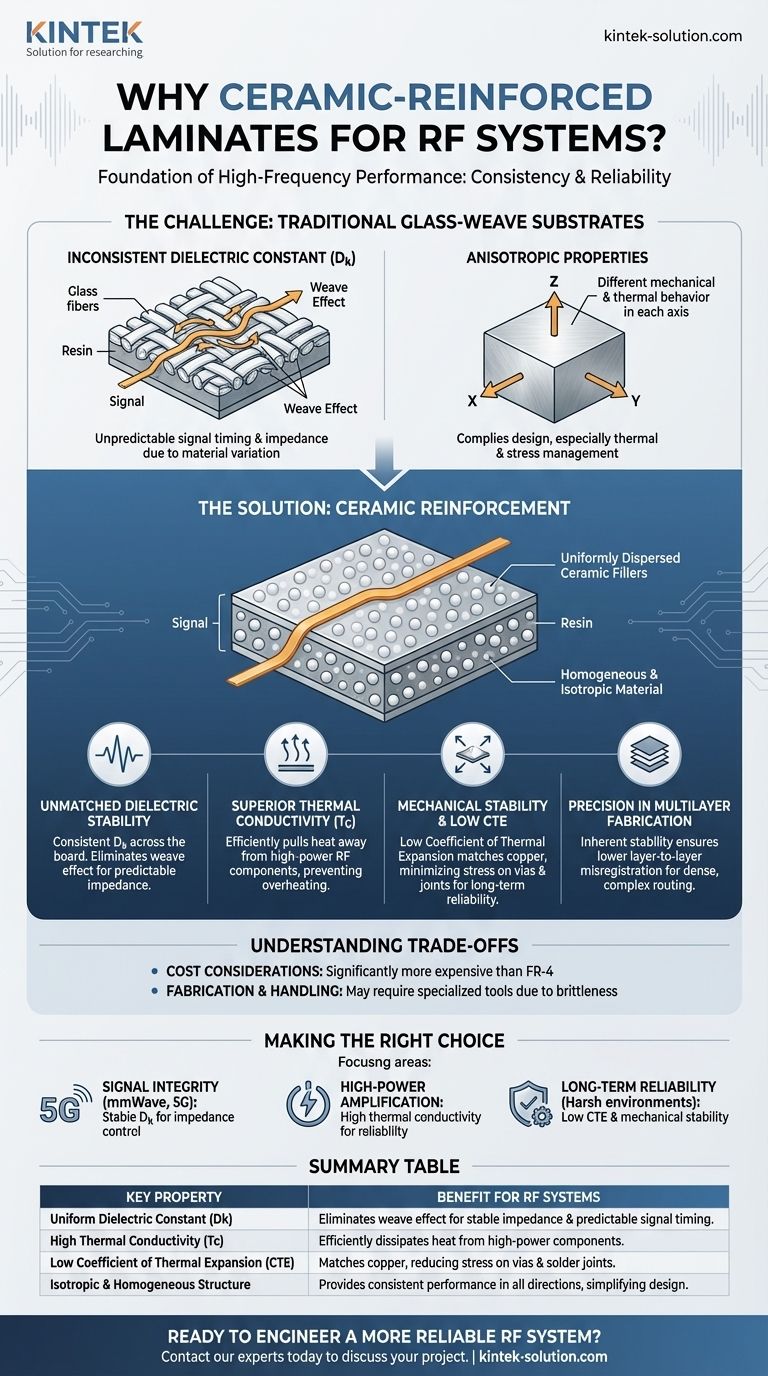

The Problem with Traditional Glass-Weave Substrates

Before appreciating the benefits of ceramic reinforcement, it's essential to understand the inherent limitations of conventional materials like woven-glass reinforced FR-4, which become significant at RF and microwave frequencies.

Inconsistent Dielectric Constant (Dk)

A standard PCB substrate uses a weave of glass fibers. This pattern creates microscopic areas where the signal trace crosses over a glass bundle and areas where it passes over the resin-filled gap between bundles.

This variation creates localized changes in the dielectric constant (Dk), a phenomenon known as the "weave effect." At high frequencies, this inconsistency can distort signal timing and impedance, degrading overall performance.

Anisotropic Material Properties

The woven glass structure is anisotropic, meaning its mechanical and thermal properties are different in the X, Y, and Z axes. This complicates design, especially when managing heat dissipation or mechanical stress across a multilayer board.

How Ceramic Reinforcement Solves Core RF Challenges

Ceramic-reinforced laminates overcome these issues by using microscopic ceramic particles evenly distributed within a resin system. This creates a uniform, predictable, and high-performance medium for RF signals.

Unmatched Dielectric Stability

The primary advantage is a homogeneous and isotropic material. Because the ceramic fillers are uniformly dispersed, the dielectric constant remains consistent across the entire board, regardless of direction or location.

This eliminates the weave effect, ensuring that transmission lines have a predictable and stable impedance. This is non-negotiable for sensitive applications like filters, couplers, and high-frequency antenna feeds.

Superior Thermal Conductivity (Tc)

High-power RF components, such as power amplifiers, generate significant heat. Ceramic fillers have much higher thermal conductivity than glass or resin, allowing them to efficiently pull heat away from these components and dissipate it through the board.

This improved thermal management increases the reliability and performance of active devices, preventing failures due to overheating.

Mechanical Stability and Low CTE

Ceramics offer excellent dimensional stability. A crucial property is a low Coefficient of Thermal Expansion (CTE) that can be engineered to closely match that of copper.

When the board heats and cools, a low CTE mismatch between the laminate and the copper traces minimizes stress on solder joints, vias, and component pads. This drastically improves the long-term reliability of the assembly, especially in environments with frequent temperature swings.

Precision in Multilayer Fabrication

The inherent stability of ceramic-reinforced materials leads to lower layer-to-layer misregistration during the fabrication of multilayer PCBs. This ensures that vias and interconnects align perfectly, which is critical for the dense, complex routing found in modern RF systems.

Understanding the Trade-offs

While offering superior performance, ceramic-reinforced laminates are not a universal solution. An objective assessment requires acknowledging their limitations.

Cost Considerations

These advanced materials are significantly more expensive than standard FR-4. The cost is justified by the performance requirements of the application, but it is a primary factor in material selection for less demanding projects.

Fabrication and Handling

Some ceramic-filled materials can be more brittle than traditional laminates. Fabricators may need specialized tools or processes to drill, cut, and handle these materials without causing micro-fractures or other damage.

Making the Right Choice for Your System

Selecting the appropriate substrate depends entirely on the primary goal of your RF design.

- If your primary focus is signal integrity at extreme frequencies (e.g., mmWave, 5G): The stable and uniform dielectric constant of ceramic laminates is essential to control impedance and prevent signal degradation.

- If your primary focus is high-power amplification: Prioritize materials with the highest thermal conductivity to ensure the reliability and longevity of your active components.

- If your primary focus is long-term reliability in harsh environments: The low CTE and superior mechanical stability are the most critical factors for preventing failures from thermal cycling.

Ultimately, choosing the right laminate is a foundational engineering decision that directly enables the performance and reliability of any advanced RF system.

Summary Table:

| Key Property | Benefit for RF Systems |

|---|---|

| Uniform Dielectric Constant (Dk) | Eliminates weave effect for stable impedance and predictable signal timing. |

| High Thermal Conductivity (Tc) | Efficiently dissipates heat from high-power components like amplifiers. |

| Low Coefficient of Thermal Expansion (CTE) | Matches copper, reducing stress on vias and solder joints for long-term reliability. |

| Isotropic & Homogeneous Structure | Provides consistent performance in all directions, simplifying design. |

Ready to engineer a more reliable and high-performance RF system?

The consistent, high-performance properties of ceramic-reinforced laminates are critical for success in semiconductor, medical, aerospace, and telecommunications applications. At KINTEK, we specialize in the precision manufacturing of advanced PTFE components and understand the material science behind superior RF performance.

Let us help you solve your most complex design challenges with custom fabrication, from prototypes to high-volume production.

Contact our experts today to discuss how our components can enhance your next project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Three Neck Flasks for Advanced Chemical Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support