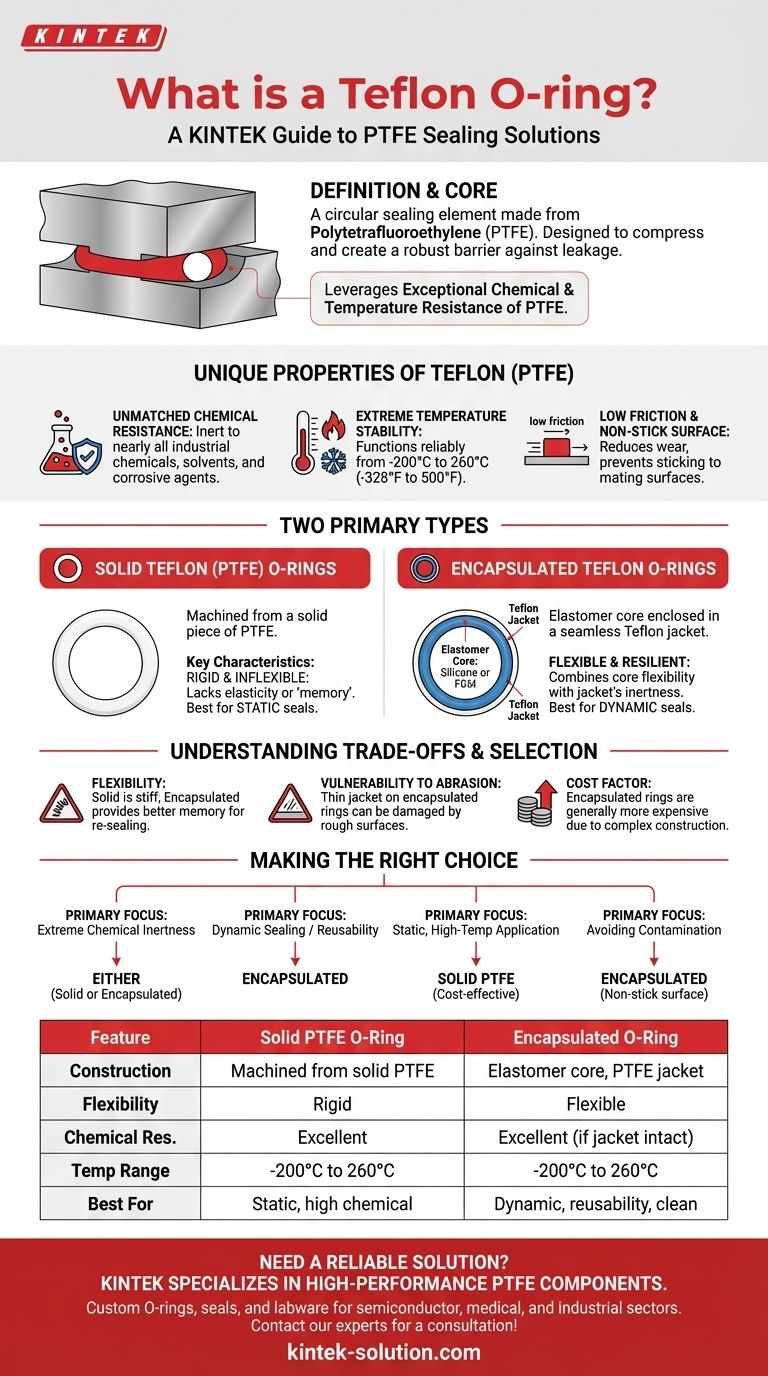

At its core, a Teflon O-ring is a circular sealing element made from the synthetic fluoropolymer Polytetrafluoroethylene (PTFE). It is designed to be seated in a groove and compressed between two or more parts, creating a robust seal that prevents the leakage of liquids or gases in a wide range of industrial equipment.

A Teflon O-ring leverages the exceptional chemical and temperature resistance of PTFE. The critical decision is choosing between a solid PTFE ring for static applications and an encapsulated ring, which combines a flexible core with a PTFE jacket for more demanding dynamic seals.

The Unique Properties of Teflon (PTFE)

To understand why Teflon is used for demanding sealing applications, we must first look at the material itself.

What is Teflon?

Teflon is the well-known trademark for PTFE, a synthetic polymer composed of carbon and fluorine atoms. This unique chemical structure makes it one of the most stable and inert materials available.

Unmatched Chemical Resistance

The strong carbon-fluorine bonds in PTFE make it resistant to nearly all industrial chemicals, solvents, and corrosive agents. This inertness ensures the seal's integrity is not compromised by the media it contains.

Extreme Temperature Stability

Teflon performs reliably across an exceptionally broad temperature range, typically from -200°C to 260°C (-328°F to 500°F). This allows it to function in environments where common elastomers would fail.

Low Friction and Non-Stick Surface

PTFE has an extremely low coefficient of friction, one of the lowest of any solid material. This self-lubricating, non-stick property reduces wear and prevents the seal from sticking to mating surfaces.

Two Primary Types of Teflon O-Rings

It is critical to distinguish between the two main constructions of Teflon O-rings, as their performance characteristics differ significantly.

Solid Teflon (PTFE) O-Rings

These are machined from a solid piece of PTFE. They offer the full chemical and thermal resistance of the material but are relatively rigid and inflexible.

Solid PTFE O-rings lack the "memory" or elasticity of rubber seals, meaning they don't spring back to their original shape well after being compressed.

Encapsulated Teflon O-Rings

This construction features an elastomer core, typically made of Silicone or FKM, which is completely enclosed in a seamless Teflon jacket.

The inner core provides the flexibility, resilience, and memory of a traditional rubber O-ring, while the outer jacket provides the chemical inertness and temperature resistance of Teflon.

Understanding the Trade-offs

Choosing the right Teflon O-ring requires understanding the inherent limitations and balancing performance against cost.

The Challenge of Flexibility

Solid PTFE O-rings are stiff. Their lack of elasticity makes them best suited for static, face-seal applications where they are not required to move or be frequently re-sealed.

Encapsulated rings solve this problem, but the Teflon jacket is thin and can be damaged.

Vulnerability to Abrasion

The protective Teflon jacket on an encapsulated O-ring is prone to scratching or damage in applications with abrasive media or rough mating surfaces. Any breach in the jacket can expose the inner core and compromise the seal.

The Cost Factor

Due to their complex, multi-material construction, encapsulated O-rings are generally more expensive than their solid PTFE counterparts. The improved flexibility and sealing performance come at a higher price point.

Making the Right Choice for Your Application

Your selection should be driven by the specific demands of the environment and the mechanical function of the seal.

- If your primary focus is extreme chemical inertness: Either a solid or encapsulated Teflon O-ring is an excellent choice due to PTFE's inherent resistance.

- If your primary focus is dynamic sealing or reusability: The superior flexibility and memory of an encapsulated O-ring is necessary.

- If your primary focus is a static, high-temperature application: A solid PTFE O-ring can provide a cost-effective and reliable seal.

- If your primary focus is avoiding contamination: The non-stick, inert surface of a Teflon jacket makes encapsulated rings ideal for food, medical, or semiconductor applications.

Ultimately, selecting the correct O-ring means matching the unique benefits of Teflon with the mechanical realities of your design.

Summary Table:

| Feature | Solid PTFE O-Ring | Encapsulated O-Ring |

|---|---|---|

| Construction | Machined from solid PTFE | Elastomer core with PTFE jacket |

| Flexibility | Rigid, best for static seals | Flexible, ideal for dynamic seals |

| Chemical Resistance | Excellent | Excellent (unless jacket is breached) |

| Temperature Range | -200°C to 260°C (-328°F to 500°F) | -200°C to 260°C (-328°F to 500°F) |

| Best For | Static applications, high chemical exposure | Dynamic sealing, reusability, contamination control |

Need a Reliable Teflon O-Ring Solution?

KINTEK specializes in manufacturing high-performance PTFE components, including custom O-rings, seals, and labware. Whether you require the absolute chemical resistance of a solid PTFE seal or the dynamic flexibility of an encapsulated design, our precision production and custom fabrication services—from prototypes to high-volume orders—ensure a perfect fit for your application.

Let us help you solve your toughest sealing challenges in the semiconductor, medical, laboratory, and industrial sectors. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability