The primary factors affecting your choice between a Teflon sheet and parchment paper for heat pressing are the desired finish of your design, the durability and long-term cost of the material, and its specific heat transfer properties. Teflon provides a reusable, non-stick surface that imparts a glossy finish, while parchment paper is a disposable option that results in a more natural, matte finish.

The decision is not about which cover sheet is universally "better," but which is the correct tool for your specific project. Your choice directly controls the final look and feel of your pressed design, making it a critical step for achieving professional results.

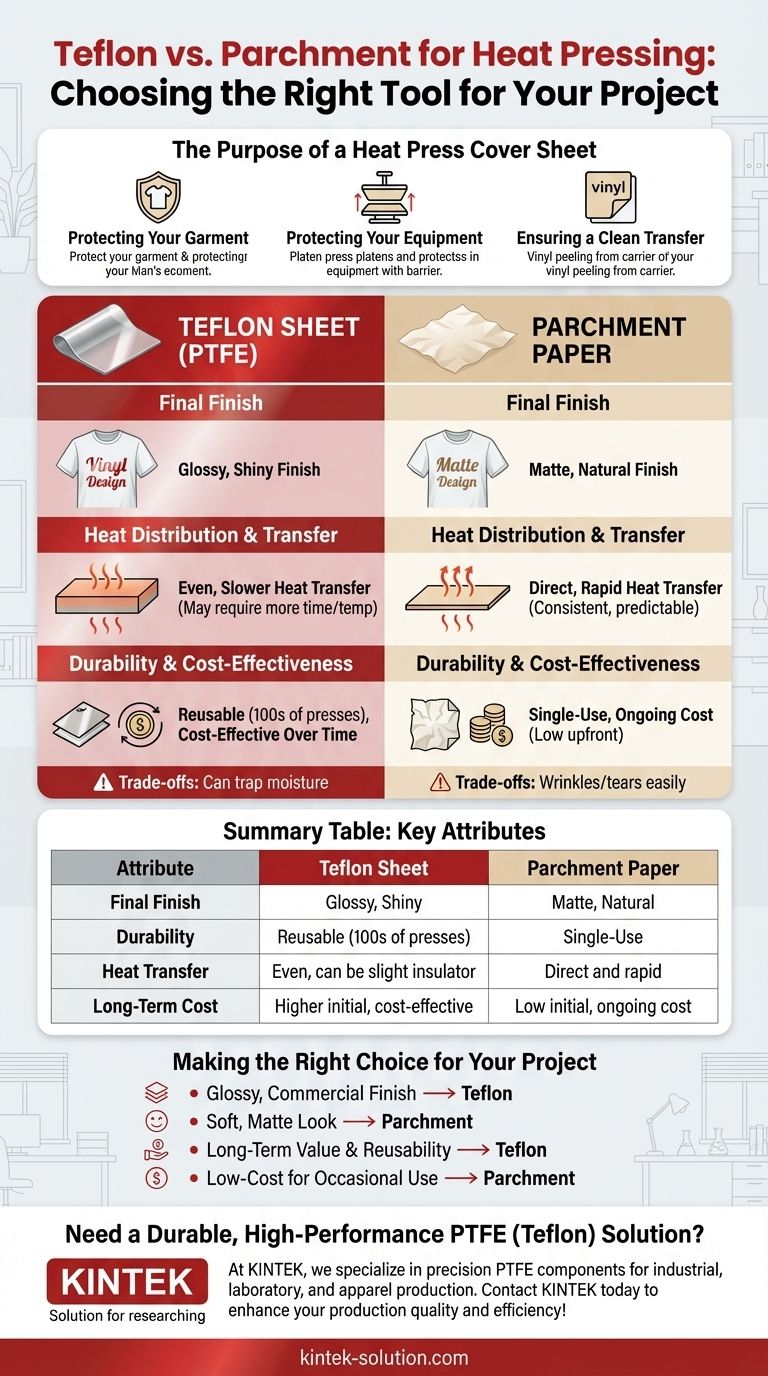

The Purpose of a Heat Press Cover Sheet

Before comparing the two, it's essential to understand why a cover sheet is non-negotiable in heat pressing. Its role is to act as a protective barrier.

Protecting Your Garment

A cover sheet shields your fabric from direct contact with the high-temperature heat platen. This is crucial for preventing scorching or discoloration, especially on delicate or light-colored materials.

Protecting Your Equipment

It also protects your heat platen. The sheet prevents inks, dyes, and adhesives from transferring from your design onto the platen, which can lead to staining and ghosting on subsequent projects.

Ensuring a Clean Transfer

Finally, the non-stick surface ensures that the heat transfer vinyl (HTV) or other media releases cleanly without smudging or sticking to the platen, resulting in a crisp, professional application.

Comparing Key Attributes: Teflon vs. Parchment

While both materials serve the same fundamental purpose, their distinct properties lead to very different outcomes and usage experiences.

The Impact on Final Finish

This is the most significant visual difference. A Teflon sheet will press the design flat and impart a shiny, glossy finish to the vinyl.

In contrast, parchment paper absorbs more texture and leaves a flat, matte finish. This allows the design to blend more naturally with the texture of the fabric.

Heat Distribution and Transfer

Teflon sheets are thicker than parchment paper. This quality helps distribute heat evenly but can also act as a slight insulator, sometimes requiring a minor increase in pressing time or temperature.

Parchment paper is thinner, allowing for a more direct and rapid transfer of heat. Many users feel this provides a very consistent and predictable press every time.

Durability and Cost-Effectiveness

Teflon sheets are the clear winner for longevity. They are highly durable and can be reused hundreds, if not thousands, of times, making them a cost-effective investment over the long term.

Parchment paper is essentially a disposable, single-use item. While its upfront cost is very low, the need to constantly replace it can add up over time for high-volume producers.

Understanding the Trade-offs

Neither option is perfect for every scenario. Choosing the right one means understanding their respective limitations.

When Teflon Can Be Problematic

The glossy finish created by Teflon is not always desirable, especially if you want a softer, more integrated look. Its thickness can also sometimes trap moisture, which may affect certain types of transfers.

The Limitations of Parchment Paper

The primary drawback of parchment is its lack of durability. It can easily wrinkle or tear, and a wrinkled sheet can transfer that texture into your final press. It is a consumable supply that must be regularly replenished.

Making the Right Choice for Your Project

Use your intended outcome to guide your decision.

- If your primary focus is a glossy, commercial finish: A Teflon sheet is the ideal tool to give your designs that professional shine.

- If your primary focus is a soft, matte look that blends into the fabric: Parchment paper will deliver the subtle, integrated finish you need.

- If your primary focus is long-term value and reusability: Investing in a quality Teflon sheet will be more cost-effective over time.

- If your primary focus is a low-cost option for occasional use: Parchment paper is an inexpensive and perfectly suitable solution.

By understanding how each material interacts with heat and your design, you gain precise control over the final outcome of every press.

Summary Table:

| Attribute | Teflon Sheet | Parchment Paper |

|---|---|---|

| Final Finish | Glossy, Shiny | Matte, Natural |

| Durability | Reusable (100s of presses) | Single-Use |

| Heat Transfer | Even, can be a slight insulator | Direct and rapid |

| Long-Term Cost | Higher initial, cost-effective over time | Low initial, ongoing cost |

Need a Durable, High-Performance PTFE (Teflon) Solution for Your Heat Pressing?

At KINTEK, we specialize in manufacturing precision PTFE components, including reusable heat press sheets and custom labware. Our sheets are engineered for superior non-stick performance, even heat distribution, and long-lasting durability—perfect for the demanding needs of industrial, laboratory, and specialized apparel production.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get the exact specifications for your application.

Contact KINTEK today to discuss how our PTFE components can enhance your production quality and efficiency!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments