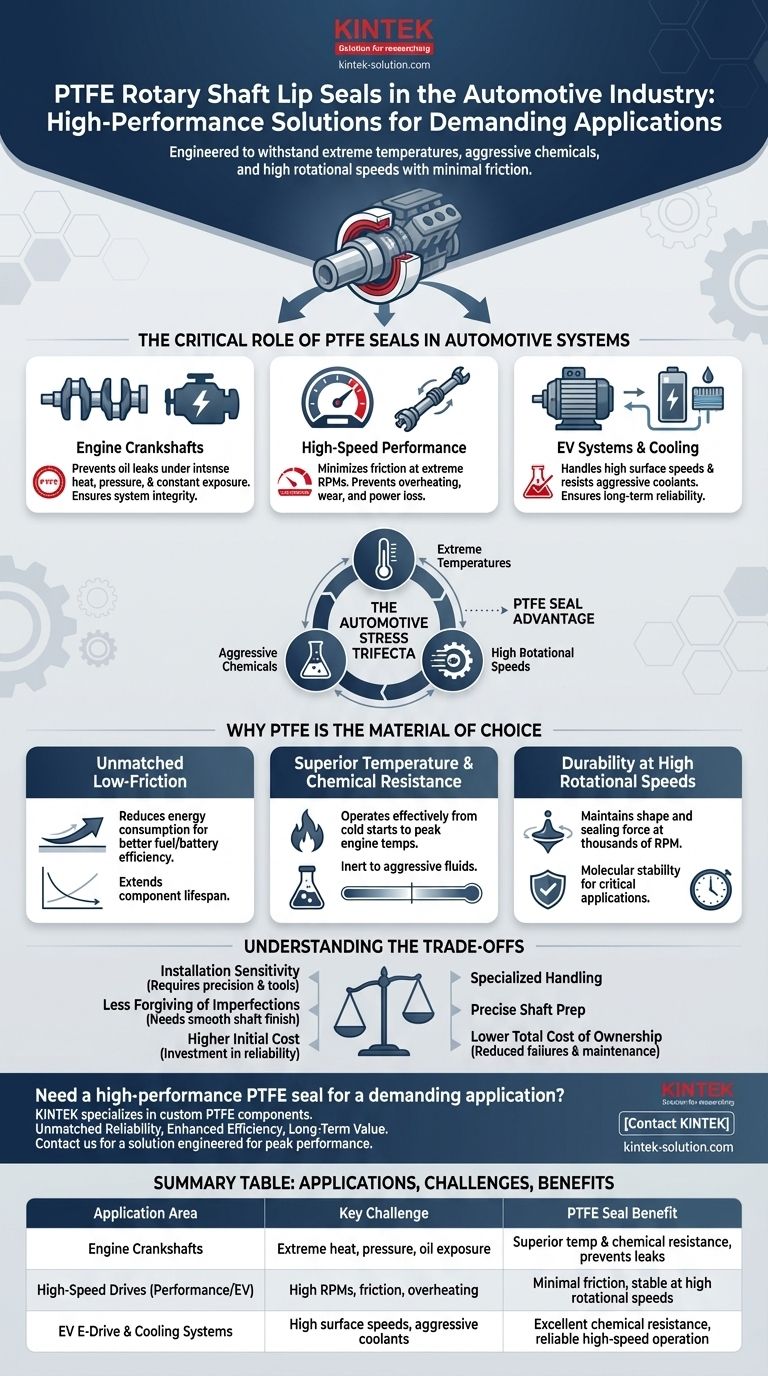

In the automotive industry, Polytetrafluoroethylene (PTFE) rotary shaft lip seals are utilized in the most demanding, high-performance applications where standard seals would fail. They are specifically engineered to prevent fluid leakage in critical components like engine crankshafts, high-speed drive shafts in performance vehicles, and within the e-drive and cooling systems of modern electric vehicles (EVs).

The core reason PTFE seals are chosen for automotive use is their unique ability to withstand the trifecta of automotive stress: extreme temperatures, aggressive chemicals, and high rotational speeds, all while operating with minimal friction.

The Critical Role of PTFE Seals in Automotive Systems

PTFE seals are not a general-purpose solution; they are a high-performance component deployed where operational demands are highest. Their application is directly tied to improving reliability and efficiency in the most vital parts of a vehicle's powertrain.

Preventing Leaks in Engine Crankshafts

The engine crankshaft is a primary application for PTFE seals. This location experiences intense heat, high pressure, and constant exposure to engine oil and its additives.

A PTFE seal here ensures that oil stays within the engine, preventing leaks that can lead to engine failure, increased emissions, and environmental contamination.

Enabling High-Speed Performance

In performance applications, such as NASCAR engine drive shafts or the e-drive systems in EVs, components rotate at extremely high speeds.

Standard elastomeric (rubber) seals can generate significant friction at these speeds, leading to overheating, premature wear, and power loss. PTFE's low coefficient of friction allows it to glide smoothly over the shaft, minimizing heat buildup and maintaining a reliable seal.

Supporting Modern Electric Vehicle (EV) Systems

The move to electric vehicles has created new challenges for sealing technology. EV e-drives operate at very high RPMs, demanding seals that can handle the surface speeds without failing.

Furthermore, EV cooling systems use specialized fluids that require the superior chemical resistance offered by PTFE to ensure long-term system integrity.

Why PTFE is the Material of Choice

The selection of PTFE is a deliberate engineering decision based on its fundamental material properties, which are perfectly suited for the harsh conditions inside a modern vehicle.

Unmatched Low-Friction Operation

PTFE has one of the lowest coefficients of friction of any solid material. This property is critical because it reduces the energy required to turn the shaft, directly contributing to better fuel or battery efficiency.

This low-friction nature also drastically reduces wear on both the seal and the shaft, extending the service life of both components and lowering maintenance costs.

Superior Temperature and Chemical Resistance

The environment inside an engine bay is incredibly hostile. PTFE can operate effectively across a wide temperature range, from cold starts to the peak operating temperatures of an engine.

It is also virtually inert, meaning it will not degrade when exposed to aggressive synthetic oils, coolants, and other automotive fluids.

Durability at High Rotational Speeds

The molecular stability of PTFE allows it to maintain its shape and sealing force even when the shaft it is sealing is rotating at thousands of RPM.

This makes it the only viable choice for many modern high-speed automotive and aerospace applications where other materials would quickly fail.

Understanding the Trade-offs

While PTFE seals offer exceptional performance, they are not a universal solution. Understanding their specific requirements is key to successful implementation.

Installation Sensitivity

PTFE seals are significantly more rigid than their rubber counterparts. They are less forgiving of improper handling and require specialized tools for installation.

If the sealing lip is scratched or bent during installation, it will almost certainly cause a leak. Proper technique is non-negotiable.

Less Forgiving of Shaft Imperfections

Because PTFE is not as elastic as rubber, it has a reduced ability to conform to minor imperfections like scratches or grooves on the shaft's surface.

For a PTFE seal to work effectively, the shaft surface finish must be exceptionally smooth and meet precise specifications.

Higher Initial Cost

As a high-performance material, PTFE seals typically have a higher upfront cost than standard nitrile or Viton seals.

This cost is justified by their extended lifespan, enhanced reliability, and the prevention of costly failures in critical systems, making it a decision based on total cost of ownership rather than initial price.

Making the Right Choice for Your Application

Choosing the correct seal requires matching the material's properties to the operational demands of the system.

- If your primary focus is maximum durability in a hot, chemically aggressive environment like an engine crankshaft: PTFE is the definitive choice for long-term reliability.

- If your primary focus is enabling high-RPM systems like EV powertrains or performance drive shafts: The low-friction and high-speed capabilities of PTFE are essential for preventing overheating and premature wear.

- If your primary focus is a standard, lower-speed application with a moderate operating environment: A traditional elastomeric seal may provide a more cost-effective solution.

Ultimately, selecting a PTFE rotary shaft seal is a strategic decision to invest in performance and reliability where it matters most.

Summary Table:

| Application Area | Key Challenge | PTFE Seal Benefit |

|---|---|---|

| Engine Crankshafts | Extreme heat, pressure, oil exposure | Superior temperature & chemical resistance, prevents leaks |

| High-Speed Drives (Performance/EV) | High RPMs, friction, overheating | Minimal friction, stable at high rotational speeds |

| EV E-Drive & Cooling Systems | High surface speeds, aggressive coolants | Excellent chemical resistance, reliable high-speed operation |

Need a high-performance PTFE seal for a demanding automotive application?

KINTEK specializes in the precision manufacturing of custom PTFE components, including seals, liners, and labware. We serve the semiconductor, medical, laboratory, and specialized industrial sectors, including automotive. Our expertise ensures you get a seal that delivers:

- Unmatched Reliability: Withstand extreme temperatures, aggressive chemicals, and high rotational speeds.

- Enhanced Efficiency: Our PTFE seals' low friction contributes to better fuel or battery efficiency.

- Long-Term Value: Reduce maintenance costs and prevent costly failures in critical systems.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders.

Contact KINTEK today to discuss your specific requirements and get a solution engineered for peak performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What types of media can PTFE lined ball valves handle? Handle Corrosive Fluids Safely

- Can PTFE rotary shaft seals be customized for specific needs? Tailor for Speed, Temperature & Chemical Resistance

- What material are PTFE ring gaskets made from? Unlock Superior Chemical & Thermal Sealing

- What are the pros and cons of PTFE Lined Gate Valves? Unlock Reliable Corrosion Control

- How are custom PTFE parts used in the automotive sector? Enhance Vehicle Performance & Durability

- How do PTFE sliding bearings work? Support Heavy Loads with Minimal Friction

- What is the pH range that PTFE Enveloped Gaskets can handle? Achieve Universal Chemical Resistance

- What are the benefits of using unreinforced PTFE materials? Unmatched Purity and Electrical Performance