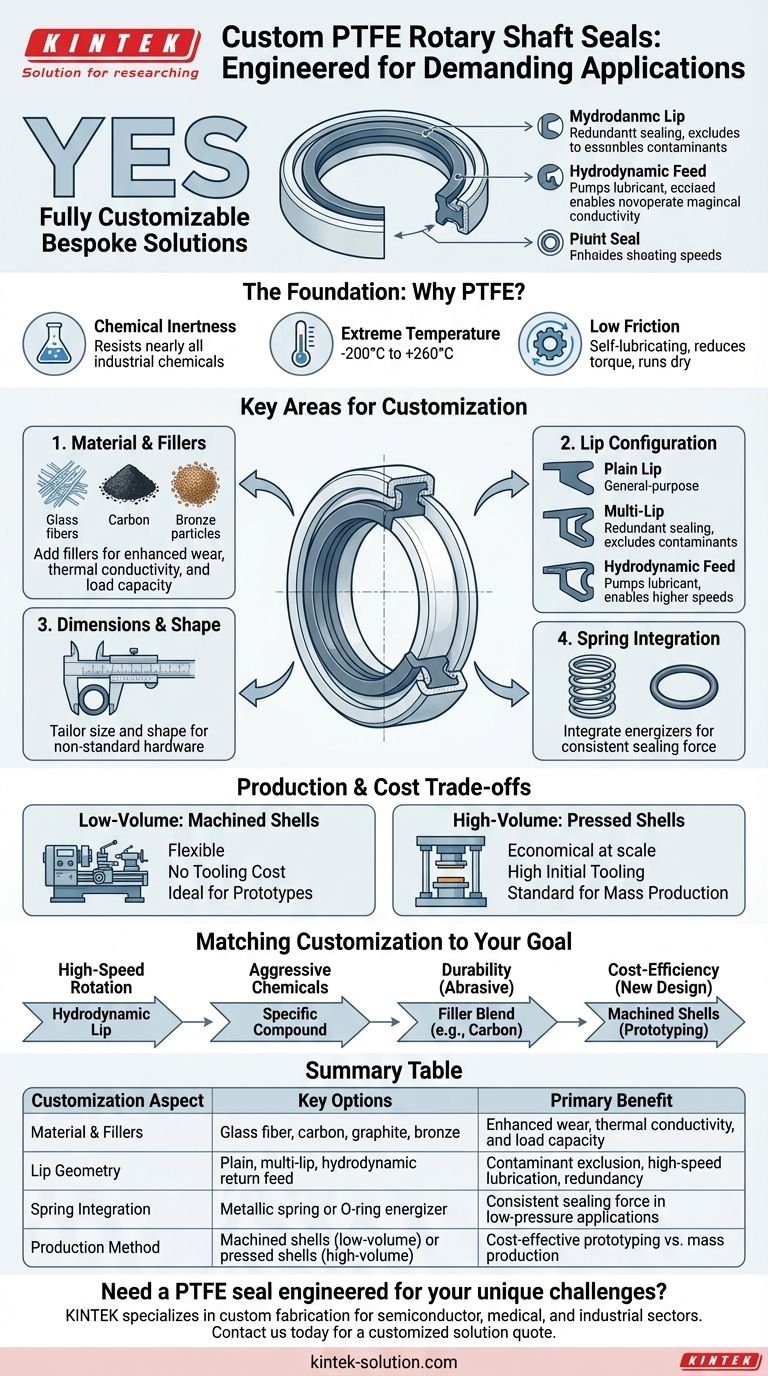

Yes, absolutely. PTFE rotary shaft seals are not only customizable; they are often engineered as bespoke solutions for demanding applications. Manufacturers can tailor nearly every aspect of the seal, from its core material composition and physical dimensions to its specific lip geometry, to meet precise operational requirements.

The ability to customize a PTFE seal goes far beyond simply changing its size. It involves strategically engineering the material, lip design, and construction to create a high-performance sealing solution perfectly matched to the specific challenges of speed, temperature, pressure, and chemical environment.

The Foundation: Why PTFE is the Ideal Choice

Polytetrafluoroethylene, or PTFE, is a synthetic fluoropolymer that serves as the base for these high-performance seals. Its inherent properties make it an exceptional starting point for custom engineering.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals and aggressive fluids. This makes it a reliable choice for applications in chemical processing, pharmaceuticals, and oil and gas where seals are exposed to corrosive media.

Extreme Temperature Tolerance

Standard PTFE seals operate effectively in a vast temperature range, typically from -200°C to +260°C (-328°F to +500°F). This stability is critical for aerospace, automotive, and industrial applications involving extreme heat or cryogenic conditions.

Exceptionally Low Friction

The material has one of the lowest coefficients of friction of any solid, making it self-lubricating. This reduces torque, minimizes heat generation at the contact point, and allows the seal to run dry, significantly reducing maintenance needs and extending service life.

Key Areas for Customization

When a standard seal won't suffice, engineers can modify several key elements to optimize performance for a specific task.

Material Composition and Fillers

While virgin PTFE is effective, its performance can be greatly enhanced by adding fillers. Materials like glass fiber, carbon, graphite, or bronze can be blended into the PTFE to improve wear resistance, thermal conductivity, and resistance to deformation under load.

Lip Configuration and Geometry

The design of the sealing lip is critical. Customization allows for flexible lip designs to create tailored solutions for specific challenges.

- Plain lips are suitable for general-purpose sealing.

- Multi-lip configurations provide redundant sealing points, ideal for excluding external contaminants.

- Hydrodynamic return feed features can be machined into the lip to actively pump lubricant back into the system, enabling higher rotational speeds and tighter sealing.

Dimensions and Physical Shape

The most basic form of customization involves tailoring the seal's size and shape to fit non-standard hardware. This ensures a perfect fit, which is the foundation of any effective sealing system.

Spring Integration

For applications with low pressure or where consistent sealing force is required over time, a metallic spring or O-ring can be integrated into the seal design. This "energizer" ensures the lip maintains constant contact with the shaft.

Understanding the Trade-offs: Production and Cost

The manufacturing method for the seal's housing, or shell, directly impacts project costs and scalability. Understanding this trade-off is crucial for both prototyping and mass production.

Low-Volume Production: Machined Shells

For prototypes, low-volume production runs, or very large seals, manufacturers can use machined shells. This process avoids the high upfront cost of creating dedicated tooling, making it a flexible and cost-effective option for initial testing or specialized equipment.

High-Volume Production: Pressed Shells

When an application requires thousands of seals, pressed shells become far more economical. While this method requires a significant initial investment in tooling, it drastically reduces the per-unit cost, making it the standard for mass production in industries like automotive.

Matching Customization to Your Sealing Goal

Choosing the right custom features depends entirely on your primary operational challenge.

- If your primary focus is high-speed rotation: Specify a hydrodynamic lip design to ensure proper lubrication and prevent premature wear.

- If your primary focus is aggressive chemical exposure: Work with the manufacturer to select a PTFE compound and filler that offers proven compatibility with the specific fluids involved.

- If your primary focus is durability in an abrasive environment: Prioritize a material blend with fillers like carbon or glass fiber to enhance wear resistance.

- If your primary focus is cost-efficiency for a new design: Begin with machined shells for prototyping and validation before committing to the tooling costs of pressed shells for mass production.

By leveraging these customization options, you can engineer a sealing solution that is purpose-built to succeed in its environment.

Summary Table:

| Customization Aspect | Key Options | Primary Benefit |

|---|---|---|

| Material & Fillers | Glass fiber, carbon, graphite, bronze | Enhanced wear, thermal conductivity, and load capacity |

| Lip Geometry | Plain, multi-lip, hydrodynamic return feed | Contaminant exclusion, high-speed lubrication, redundancy |

| Spring Integration | Metallic spring or O-ring energizer | Consistent sealing force in low-pressure applications |

| Production Method | Machined shells (low-volume) or pressed shells (high-volume) | Cost-effective prototyping vs. mass production |

Need a PTFE seal engineered for your unique challenges?

KINTEK specializes in custom PTFE component fabrication for the semiconductor, medical, laboratory, and industrial sectors. We leverage precision engineering to deliver solutions tailored to your exact requirements for speed, temperature, chemical resistance, and durability—from initial prototypes to high-volume production.

Contact us today to discuss your application and receive a customized solution quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- In which industries are PTFE tri clamp gaskets commonly used? Essential for Purity & Chemical Resistance

- How do PTFE expansion bellows contribute to pollution control systems? Enhance System Integrity & Safety

- What industries commonly use ePTFE gasket material? Ensure Purity, Safety, and Reliability

- What are some medical applications of PTFE energized seals? Ensuring Reliability and Purity in Medical Devices

- Why are ceramic-reinforced laminates preferred in RF systems? Superior Signal Integrity & Thermal Management

- What are the key properties of Teflon (PTFE) used in custom parts? | Achieve Peak Performance

- Are metric sizes available for PTFE balls? Ensuring Precision with the Right Tolerance

- What are the advantages of square rings over O-rings in static applications? Achieve Superior High-Pressure Sealing