In the automotive sector, custom PTFE parts are primarily used for high-performance seals, gaskets, and bushings where reducing friction and resisting extreme conditions are critical. These components are essential in engines, transmissions, and fuel systems, directly contributing to improved vehicle durability, reliability, and fuel efficiency by minimizing mechanical wear and preventing fluid leaks.

The core reason for PTFE's adoption in automotive design is its unique combination of an extremely low coefficient of friction, high-temperature tolerance, and chemical inertness. This allows engineers to solve persistent challenges of wear, heat, and corrosion in the most demanding parts of a vehicle.

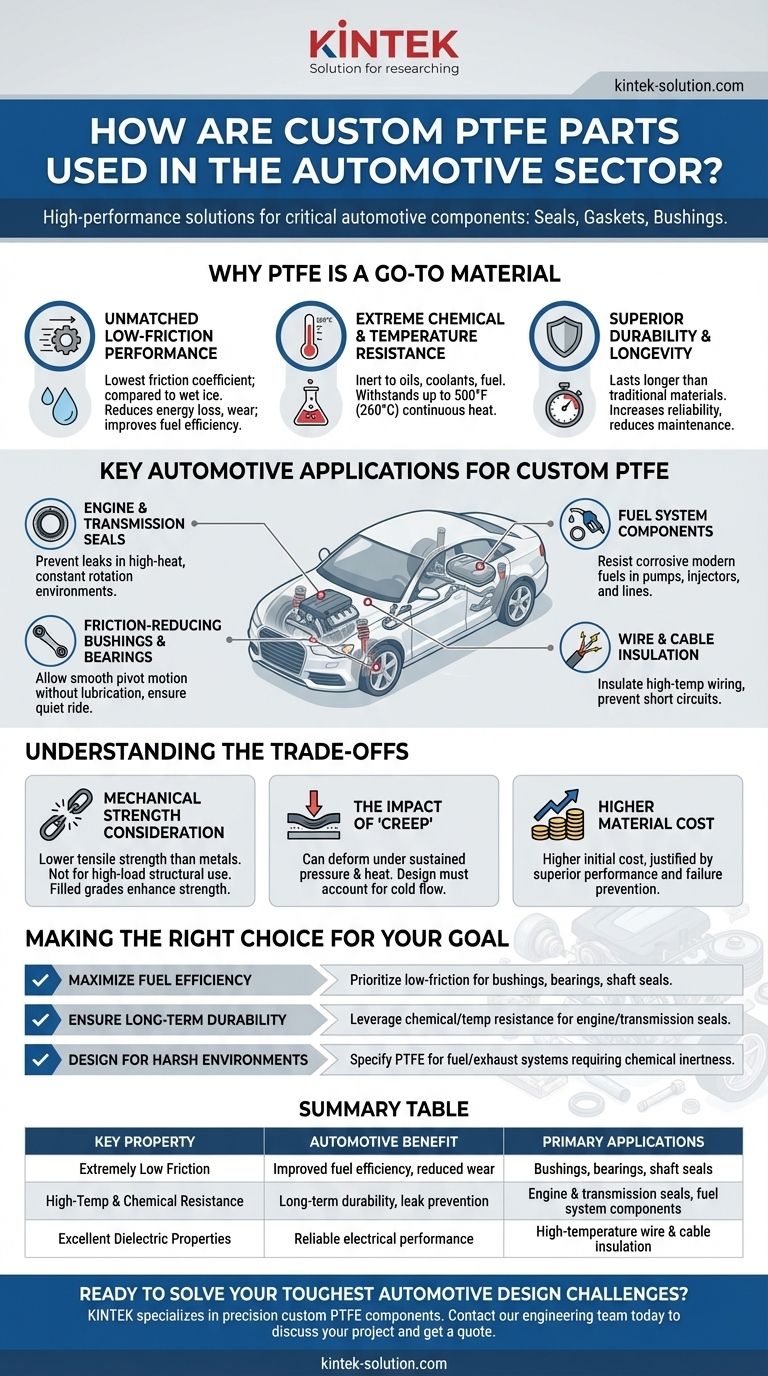

Why PTFE is a Go-To Material in Automotive Engineering

The harsh environment inside a modern vehicle—characterized by high temperatures, corrosive fluids, and constant movement—requires materials that can perform without degradation. PTFE (Polytetrafluoroethylene) possesses a unique set of properties that make it an ideal solution for these challenges.

Unmatched Low-Friction Performance

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "slipperiness" is invaluable for parts that move against each other.

By using PTFE for bushings and bearings in steering, suspension, and other systems, engineers can drastically reduce the energy lost to friction. This results in smoother operation, less wear and tear, and a direct improvement in fuel efficiency.

Extreme Chemical and Temperature Resistance

Vehicle systems rely on a variety of aggressive fluids, including engine oil, coolant, transmission fluid, and fuel. PTFE is almost completely inert, meaning it will not react with or degrade when exposed to these chemicals.

Furthermore, it can withstand continuous service temperatures up to 500°F (260°C). This makes it the perfect material for seals and gaskets inside hot engine compartments, ensuring they maintain their integrity and prevent leaks over the vehicle's lifespan.

Superior Durability and Longevity

The combination of low friction and high resistance means that PTFE components last longer than parts made from many traditional plastics or rubbers.

This inherent durability translates to increased reliability and reduced maintenance requirements, a critical factor for both manufacturers and vehicle owners.

Key Automotive Applications for Custom PTFE

While its properties are broadly applicable, custom PTFE parts are engineered for several specific and critical functions within a vehicle.

Engine and Transmission Seals

The most common application is for dynamic seals, such as crankshaft seals or transmission input/output seals. These parts must prevent oil leaks while enduring constant rotation and high temperatures, a task for which PTFE is perfectly suited.

Friction-Reducing Bushings and Bearings

In suspension systems, steering columns, and other chassis components, PTFE bushings allow parts to pivot and move smoothly without lubrication or wear. This ensures consistent performance and a quieter ride.

Fuel System Components

Modern fuels can be corrosive to certain materials. PTFE's chemical inertness makes it an excellent choice for seals, O-rings, and liners within fuel pumps, injectors, and lines, preventing degradation and ensuring system integrity.

Wire and Cable Insulation

In high-temperature areas near the engine or exhaust, PTFE is used as an insulator for electrical wiring. Its excellent dielectric properties and heat resistance prevent short circuits and ensure reliable electrical system performance.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. A clear-eyed technical assessment requires understanding its limitations.

Consideration of Mechanical Strength

PTFE is a relatively soft material with lower tensile strength and wear resistance compared to metals. It is not suitable for high-load structural applications. However, this is often overcome by creating filled PTFE grades, where additives like glass fiber or carbon are used to enhance its mechanical properties for specific applications.

The Impact of "Creep"

Under sustained pressure, especially at elevated temperatures, PTFE can slowly deform over time—a phenomenon known as "creep" or cold flow. The design of PTFE seals and gaskets must account for this characteristic to ensure a long-lasting, effective seal.

Higher Material Cost

Compared to common elastomers or plastics, PTFE can have a higher initial material cost. This cost is typically justified by its superior performance, increased component lifespan, and the prevention of costly failures in critical systems.

Making the Right Choice for Your Goal

Selecting the right material is about matching its properties to the primary engineering challenge you need to solve.

- If your primary focus is maximizing fuel efficiency: Prioritize PTFE's low-friction properties for bushings, bearings, and rotating shaft seals to minimize parasitic energy loss.

- If your primary focus is ensuring long-term durability: Leverage PTFE's exceptional chemical and temperature resistance for static and dynamic seals in the engine and transmission.

- If your primary focus is designing for harsh fluid environments: Specify PTFE for any component in the fuel or exhaust system that requires absolute chemical inertness to prevent degradation.

Ultimately, custom PTFE parts are a strategic choice for solving some of the most difficult engineering problems in the modern automobile.

Summary Table:

| Key Property | Automotive Benefit | Primary Applications |

|---|---|---|

| Extremely Low Friction | Improved fuel efficiency, reduced wear | Bushings, bearings, shaft seals |

| High-Temp & Chemical Resistance | Long-term durability, leak prevention | Engine & transmission seals, fuel system components |

| Excellent Dielectric Properties | Reliable electrical performance | High-temperature wire & cable insulation |

Ready to solve your toughest automotive design challenges?

KINTEK specializes in manufacturing precision custom PTFE components—from seals and liners to complex labware—for the automotive, semiconductor, medical, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get the exact high-performance parts you need to enhance vehicle durability, reliability, and efficiency.

Contact our engineering team today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What makes expanded PTFE gaskets more suitable for sealing applications than pure PTFE gaskets? Solve Cold Flow for Reliable Seals

- Is PTFE approved for food contact applications? Ensuring Food Safety with Compliant PTFE

- What is the temperature rating for PTFE gaskets? Maximize Performance from -200°C to 260°C

- What are some examples of PTFE's use in civil engineering? Manage Structural Movement and Load

- What are the uses of Polytetrafluoroethylene (PTFE) with Glass Fill? Boost Wear Resistance & Strength

- What are the properties of PTFE Lip Seals when blended with fillers? Enhance Performance for Demanding Seals

- What are the key roles of PTFE rotary shaft seals in industrial applications? Ensure Reliability in Extreme Conditions

- What are PTFE bellows and what are they made of? Solve Tough Chemical & Thermal Challenges