In challenging industrial environments, PTFE expansion bellows offer a superior combination of chemical inertness, temperature stability, and operational longevity that traditional alternatives like rubber or metal cannot match. Their core advantages lie in their resistance to nearly all industrial chemicals and solvents, their wide operating temperature range, and their exceptional flexibility for absorbing system movements.

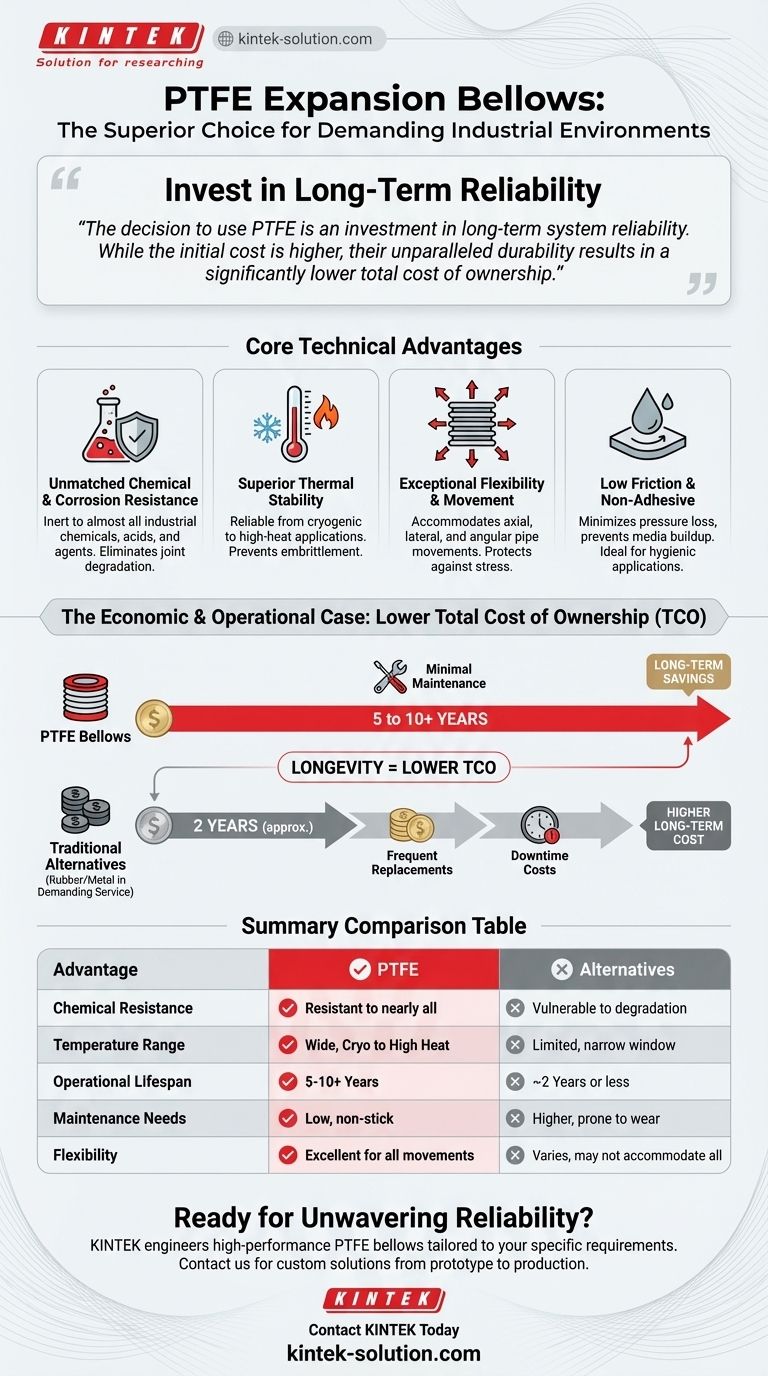

The decision to use PTFE expansion bellows is an investment in long-term system reliability. While the initial cost is higher, their unparalleled durability and low maintenance needs result in a significantly lower total cost of ownership in demanding applications.

Unpacking the Core Technical Advantages

The value of PTFE (Polytetrafluoroethylene) is rooted in its unique molecular structure, which translates directly into tangible performance benefits for expansion joints.

Unmatched Chemical and Corrosion Resistance

PTFE is virtually inert to almost all industrial chemicals, acids, and corrosive agents. This eliminates the risk of joint degradation and system contamination that can occur with rubber or metallic bellows in aggressive environments.

Superior Thermal Stability

These bellows perform reliably across a broad spectrum of temperatures, from cryogenic conditions to high-heat applications. This makes them a far more versatile solution than rubber joints, which can become brittle or degrade outside a narrow temperature window.

Exceptional Flexibility and Movement Absorption

PTFE expansion bellows are engineered to be highly flexible, effectively accommodating axial (compression/extension), lateral (offset), and angular pipe movements. This capability is critical for protecting equipment and piping from the stresses caused by thermal expansion, vibration, and system pressure changes.

Low Friction and Non-Adhesive Surface

The material has an extremely low coefficient of friction, which minimizes pressure loss and reduces energy consumption within the system. Furthermore, its non-stick surface prevents media buildup, simplifying cleaning and making it an ideal choice for hygienic applications in the food, beverage, and pharmaceutical industries.

The Economic and Operational Case for PTFE

Beyond pure technical performance, PTFE bellows provide significant long-term financial and operational advantages that justify their initial investment.

Evaluating the Total Cost of Ownership

While PTFE bellows have a higher upfront cost, their operational lifespan dramatically exceeds that of alternatives. A PTFE bellow can last 5 to 10 years or more, whereas a rubber bellow in a similar demanding service might need replacement every 2 years.

This longevity drastically reduces costs associated with replacement parts, labor, and, most importantly, process downtime.

Simplified Installation and Maintenance

PTFE bellows are lightweight and easy to handle, streamlining the installation process with minimal labor and no specialized tooling required. Once installed, their resistance to wear and material buildup means they require far less maintenance and cleaning over their service life.

Understanding the Trade-offs

No single solution is perfect for every scenario. A clear-eyed assessment of PTFE's limitations is essential for making an informed decision.

The Initial Investment

The most significant factor is the higher upfront purchase price compared to standard rubber or metal joints. This initial capital outlay must be weighed against the long-term savings in maintenance and replacement costs.

Mechanical and Pressure Limitations

While highly flexible, PTFE may not possess the same high-pressure ratings or resistance to abrasion as some specially designed metallic expansion joints. In systems with extremely high pressures or significant abrasive media, a different material may be necessary.

Not a Universal Solution

For simple, low-temperature, and non-corrosive applications, such as standard water lines, a traditional rubber expansion joint is often a more cost-effective choice. The advanced properties of PTFE provide the most value where other materials fail.

Making the Right Choice for Your System

Selecting the correct expansion bellow depends entirely on the specific demands of your application and your long-term operational goals.

- If your primary focus is handling aggressive chemicals or high temperatures: PTFE is the definitive choice for ensuring system integrity and preventing premature failure.

- If your primary focus is minimizing long-term operational costs: The superior durability and low maintenance of PTFE offer a lower total cost of ownership in any demanding environment.

- If your primary focus is a low-demand, budget-constrained application: A traditional rubber or metallic expansion joint may provide adequate performance at a lower initial cost.

Ultimately, choosing PTFE expansion bellows is an investment in unwavering reliability for your most critical and demanding processes.

Summary Table:

| Advantage | PTFE Expansion Bellows | Traditional Alternatives (e.g., Rubber/Metal) |

|---|---|---|

| Chemical Resistance | Resistant to nearly all industrial chemicals and solvents | Vulnerable to degradation from corrosive agents |

| Temperature Range | Wide range (cryogenic to high heat) | Limited, especially rubber outside narrow window |

| Operational Lifespan | 5-10+ years in demanding service | Often 2 years or less in similar conditions |

| Maintenance Needs | Low maintenance, non-stick surface prevents buildup | Higher maintenance, prone to wear and contamination |

| Flexibility | Excellent for axial, lateral, and angular movements | Varies; may not accommodate all movement types as effectively |

Ready to invest in long-term system reliability?

PTFE expansion bellows from KINTEK are engineered for superior performance in the most demanding applications. We specialize in manufacturing high-precision PTFE components, including custom expansion joints, for the semiconductor, medical, laboratory, and industrial sectors.

Our expertise ensures you get a solution tailored to your specific chemical, temperature, and pressure requirements, maximizing your system's uptime and minimizing your total cost of ownership.

Contact KINTEK today to discuss your application needs—from prototype to high-volume production—and let our experts help you achieve unwavering process integrity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts