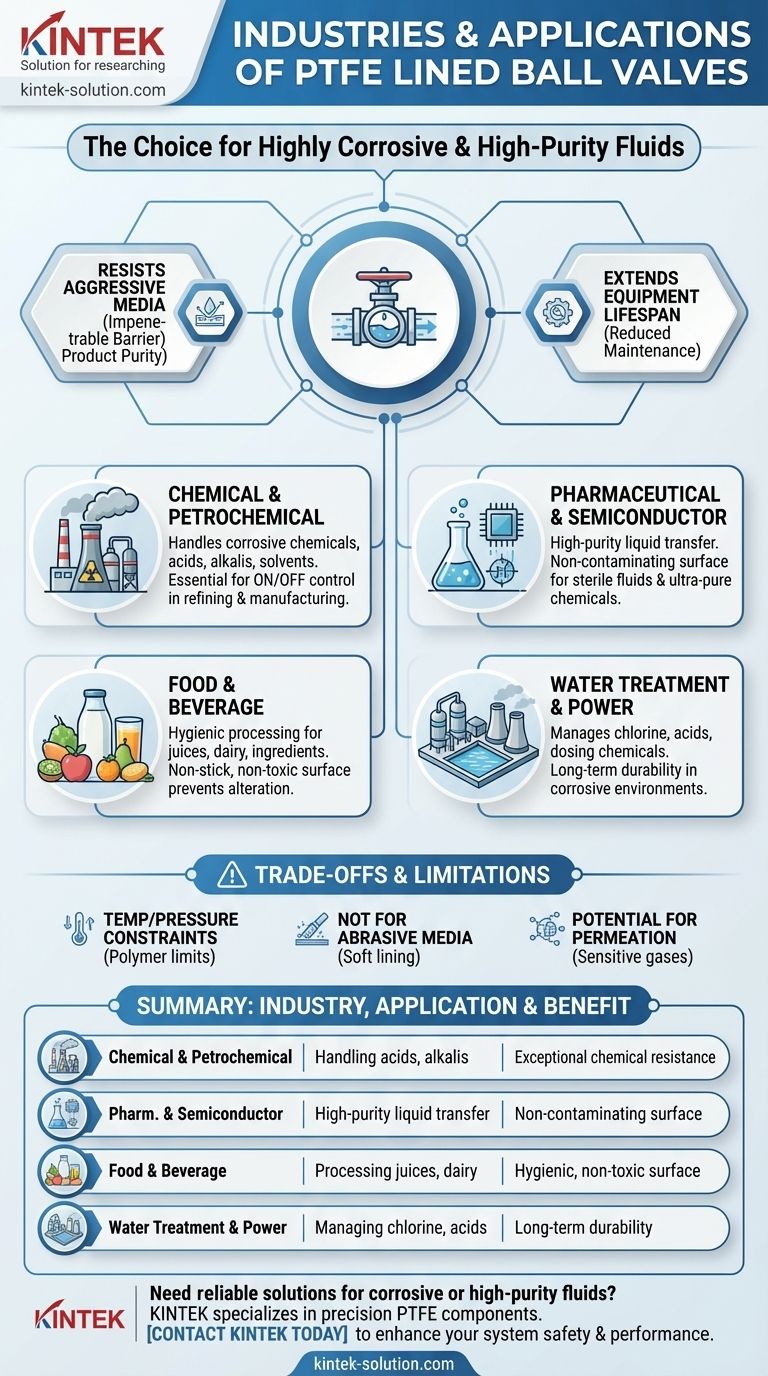

In short, PTFE lined ball valves are the valve of choice in nearly any industry that handles highly corrosive or high-purity fluids. They are most commonly found in chemical and petrochemical processing, pharmaceutical manufacturing, food and beverage production, and water treatment facilities. Their prevalence is driven by the exceptional chemical resistance of the Polytetrafluoroethylene (PTFE) lining, which protects the valve's core components from aggressive media.

The decision to use a PTFE lined ball valve is less about the industry itself and more about the nature of the fluid being controlled. These valves are the standard solution for managing highly corrosive, reactive, or pure media that would quickly degrade or become contaminated by standard metal valves.

The Core Driver: Chemical Inertness

The fundamental reason PTFE lined valves are so widespread is the unique properties of their lining. This inert barrier is the solution to problems that plague standard valves in demanding environments.

Resisting Aggressive Media

The primary function of the PTFE lining is to create an impenetrable barrier between the process fluid and the valve's metal body. This is critical when handling substances like acids, alkalis, salts, and organic solvents. Without this protection, the valve body would corrode, leading to leaks and eventual failure.

Preventing Contamination

In industries like pharmaceuticals, semiconductors, and food processing, maintaining product purity is paramount. The non-reactive and non-stick surface of PTFE ensures that nothing leaches from the valve into the fluid, preserving its integrity.

Extending Equipment Lifespan

By preventing chemical attack, the PTFE lining dramatically extends the service life of the valve. This translates directly to reduced maintenance costs, less downtime, and greater operational reliability in critical pipeline systems.

Key Industry Applications

While the principle is the same, the specific application of PTFE lined valves varies by industry.

Chemical and Petrochemical

These industries rely on PTFE lined valves for the safe handling of a vast range of corrosive chemicals and solvents. They are essential for ON/OFF control in processes involving crude oil refining, fertilizer production, and the manufacturing of specialty chemicals.

Pharmaceutical and Semiconductor

Here, the focus is on high-purity liquid transfer. The non-contaminating surface of PTFE is critical for moving sterile fluids, pharmaceutical ingredients, and the ultra-pure chemicals used in semiconductor fabrication.

Food and Beverage

The non-stick and non-toxic properties of PTFE make it ideal for handling fluids like juices, dairy products, and other ingredients. The lining ensures hygienic processing and prevents any unwanted material from altering the product's taste or quality.

Water Treatment and Power Generation

Both municipal and industrial water treatment plants use corrosive chemicals like chlorine and acids. PTFE lined valves provide the long-term durability needed to manage these substances without failing. Similarly, power stations use them in chemical dosing and cooling water systems.

Understanding the Trade-offs and Limitations

Despite their advantages, PTFE lined valves are not a universal solution. Understanding their limitations is key to proper application.

Temperature and Pressure Constraints

PTFE is a polymer, and as such, it has clear operational limits for temperature and pressure. In applications exceeding these limits (typically around 200°C or 392°F), an all-metal valve made from a specialty alloy may be required.

Not for Abrasive Media

The lining is relatively soft and is not suitable for fluids containing abrasive particles or slurries. Abrasives can quickly wear away the PTFE, exposing the metal body to chemical attack and causing the valve to fail.

Potential for Permeation

In very specific high-purity or sensitive gas applications, certain small-molecule gases can slowly permeate the PTFE lining over time. While not an issue for most liquid applications, this is a critical consideration in specialized fields.

Making the Right Choice for Your Application

Selecting the correct valve requires matching its capabilities to your primary operational goal.

- If your primary focus is handling highly corrosive chemicals: PTFE lined valves are the industry standard for preventing chemical attack and ensuring system integrity.

- If your primary focus is maintaining product purity: The non-reactive, non-leaching surface of a PTFE lining is critical for applications in the pharmaceutical, food, and semiconductor industries.

- If your primary focus is high-temperature or abrasive services: You must evaluate alternatives, as the operational limits of the PTFE lining may be exceeded, leading to premature failure.

Ultimately, choosing a PTFE lined ball valve is a strategic decision to master corrosive and high-purity environments, ensuring both safety and process reliability.

Summary Table:

| Industry | Primary Application | Key Benefit of PTFE Lining |

|---|---|---|

| Chemical & Petrochemical | Handling acids, alkalis, solvents | Exceptional chemical resistance, prevents corrosion |

| Pharmaceutical & Semiconductor | High-purity liquid transfer | Non-contaminating surface, ensures product purity |

| Food & Beverage | Processing juices, dairy, ingredients | Hygienic, non-toxic, non-stick surface |

| Water Treatment & Power | Managing chlorine, acids, dosing chemicals | Long-term durability in corrosive environments |

Need a reliable valve solution for corrosive or high-purity fluids?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including seals, liners, and custom labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we can provide the exact PTFE lined valve or component you need—from prototypes to high-volume production.

Contact KINTEK today to discuss how our custom PTFE solutions can enhance your system's safety, reliability, and performance.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the available grades of PTFE balls? Choose the Right Grade for Your Application

- How do the chemical properties of PTFE balls influence their performance? Unmatched Durability in Harsh Environments

- Why are PTFE balls particularly suitable for high-performance applications? Key Properties & Selection Guide

- What factors determine the different grades of PTFE balls available? Select the Right Grade for Your Application

- What are the key chemical properties of PTFE balls? Unmatched Chemical & Thermal Stability