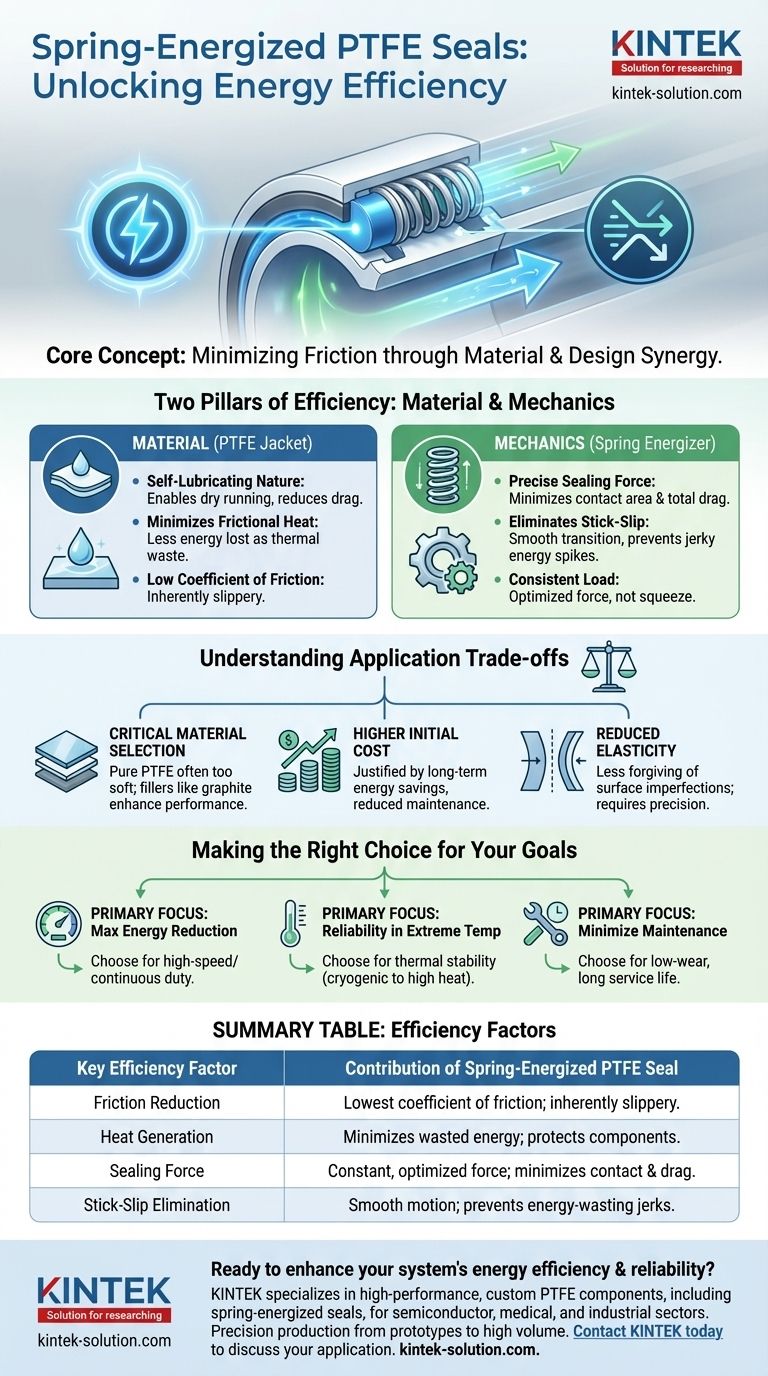

At their core, spring-energized PTFE seals improve energy efficiency by fundamentally minimizing friction. This is accomplished through a powerful synergy between the seal's material and its mechanical design. The Polytetrafluoroethylene (PTFE) jacket provides an exceptionally low-friction surface, while the internal spring applies a consistent, optimized force, drastically reducing the energy that would otherwise be lost to heat and resistance in dynamic applications.

In any dynamic system, friction is a direct tax on energy. Spring-energized PTFE seals reduce this tax by combining the self-lubricating nature of PTFE with a precisely engineered spring, ensuring the seal uses the absolute minimum energy required to maintain its integrity.

The Two Pillars of Efficiency: Material and Mechanics

The remarkable efficiency of these seals doesn't come from a single feature, but from the interplay between the PTFE seal jacket and the internal spring energizer. Each component plays a distinct and critical role in reducing energy consumption.

The Self-Lubricating Nature of PTFE

PTFE has the lowest coefficient of friction of any known solid material. This creates an inherently "slippery" surface that requires less force to move against a mating component.

This characteristic allows the seal to function in a self-lubricating manner. In many systems, this can enable continuous dry running without the need for external liquid lubricants, which themselves can introduce viscous drag and complexity.

Minimizing Frictional Heat Generation

Friction doesn't just create resistance; it generates heat. This heat is a direct form of wasted energy that can degrade lubricants, damage adjacent components, and reduce the overall efficiency of the system.

Because PTFE minimizes friction, it also minimizes heat generation. This means more of the system's input energy is converted into useful work rather than being lost as thermal waste, contributing to both efficiency and a longer service life.

The Precision of the Spring Energizer

Unlike a simple O-ring that relies on material squeeze, the spring energizer provides a constant and precise sealing force on the seal lips.

This design minimizes the contact area required to form a reliable seal. By reducing the surface area under load, the total frictional drag is significantly lowered, directly saving energy with every cycle of the equipment.

Eliminating Stick-Slip Behavior

"Stick-slip" is the jerky motion that occurs when the static (starting) friction is significantly higher than the kinetic (moving) friction. Overcoming that initial "stiction" requires a recurring spike in energy.

PTFE's static and kinetic coefficients of friction are nearly identical. This ensures a smooth transition from a static to a dynamic state, eliminating energy-wasting jerks and providing the smooth, precise motion control critical in aerospace and medical devices.

Understanding the Application Trade-offs

While highly efficient, these seals are a specialized component. An objective analysis requires understanding their specific limitations and considerations.

Material Selection is Critical

The term "PTFE" refers to a family of materials. Pure PTFE is often too soft for demanding applications.

Performance is greatly enhanced by adding fillers like graphite or carbon, which improve wear resistance and self-lubricating properties. Choosing the wrong compound for the application can negate the potential efficiency gains.

Higher Initial Cost

Spring-energized PTFE seals are typically a higher-cost component compared to standard elastomeric seals like O-rings.

The justification for their use lies in the total cost of ownership. The long-term savings from improved energy efficiency, reduced maintenance, and longer service life often outweigh the initial investment.

Reduced Elasticity

PTFE is a polymer, not an elastomer. It does not have the "rubbery" memory of materials like nitrile or FKM.

While the spring compensates for this to a large degree, these seals may be less forgiving of hardware imperfections or highly irregular sealing surfaces compared to a traditional elastomeric seal.

Making the Right Choice for Your Efficiency Goals

Selecting the correct seal is about aligning the component's strengths with your primary engineering objective.

- If your primary focus is maximum energy reduction: Spring-energized PTFE seals are an excellent choice for high-speed or continuous-duty applications where small frictional losses compound into significant energy waste.

- If your primary focus is reliability in extreme temperatures: The thermal stability of PTFE, from cryogenic lows to high heat, ensures that efficiency and seal integrity are maintained where other materials would fail.

- If your primary focus is minimizing maintenance and downtime: The low-wear, self-lubricating nature of filled PTFE leads to a longer and more predictable service life, contributing to overall system efficiency by reducing interruptions.

Ultimately, leveraging spring-energized PTFE seals is a strategic engineering decision to convert wasted frictional energy into reliable, efficient performance.

Summary Table:

| Key Efficiency Factor | Contribution of Spring-Energized PTFE Seal |

|---|---|

| Friction Reduction | PTFE jacket has the lowest coefficient of friction of any solid material. |

| Heat Generation | Minimizes wasted energy lost as thermal heat, protecting components. |

| Sealing Force | Spring provides constant, optimized force, minimizing contact area and drag. |

| Stick-Slip Elimination | Smooth motion transition prevents energy-wasting jerks and spikes. |

Ready to enhance your system's energy efficiency and reliability?

KINTEK specializes in manufacturing high-performance, custom PTFE components—including spring-energized seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services, from prototypes to high-volume orders, ensure you get a seal that minimizes friction and maximizes your operational efficiency.

Contact KINTEK today to discuss your specific application and discover how our PTFE solutions can reduce your energy costs and extend equipment life.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems