To be direct, there are no common, safe chemical solvents that effectively dissolve cured Teflon (PTFE) residue. While extremely aggressive and hazardous chemicals like benzene or certain chlorinated solvents are sometimes mentioned, they are largely ineffective at truly dissolving the polymer and pose significant health and environmental risks that far outweigh any minor loosening effect they might have.

The core challenge is that Teflon's defining feature is its extreme chemical inertness. This property makes it an excellent non-stick coating but also renders it nearly impervious to chemical dissolution. Therefore, the most practical and effective removal methods are almost always mechanical, not chemical.

The Core Challenge: Why Teflon Resists Solvents

To understand why cleaning Teflon with solvents is a losing battle, we need to look at its fundamental chemistry. The problem isn't that you haven't found the right chemical; it's that one doesn't practically exist for this purpose.

The Unbreakable Bond of Fluorine

Polytetrafluoroethylene (PTFE) is a fluoropolymer. It consists of a long chain of carbon atoms, where each carbon is completely shielded by incredibly strong carbon-fluorine bonds.

This fluorine "sheath" acts like chemical armor, protecting the vulnerable carbon backbone from attack. It is one of the strongest single bonds in organic chemistry, which is the source of Teflon's non-reactivity.

Cured vs. Uncured Material

It's crucial to distinguish between Teflon before and after it's been applied and cured. Uncured PTFE dispersions may contain carrier solvents, but the residue you're trying to clean is almost certainly sintered (cured).

During the curing process, the PTFE particles are heated and fused into a solid, durable, and highly non-porous film. This process locks in the chemical resistance, making the final coating radically different from its liquid state.

Ineffective and Dangerous Chemical Approaches

The suggestions of using powerful organic solvents are often rooted in a misunderstanding of the problem. These chemicals are designed to dissolve oils, greases, and other polymers, but they are mismatched for the unique stability of PTFE.

The Misleading Case for Solvents

Chemicals like benzene and chlorinated solvents are excellent degreasers. They might help clean contaminants off the surface of the Teflon, but they will not break down the PTFE polymer itself.

At best, some highly aggressive solvents might cause slight swelling or softening of the residue, but they will not dissolve it for easy wiping.

Extreme Health and Safety Risks

It cannot be overstated: the chemicals sometimes suggested for this task are exceptionally hazardous.

Benzene is a known carcinogen and is highly toxic. Its use outside of a controlled industrial or laboratory setting with specialized ventilation and protective equipment is extremely dangerous.

Chlorinated solvents are also heavily regulated, often toxic, and can cause severe respiratory, liver, and central nervous system damage.

The Danger of High Temperatures

A common temptation is to heat the solvent or the Teflon to increase effectiveness. This is extremely dangerous. When heated above 300°C (572°F), Teflon can begin to decompose and release toxic fluorocarbon gases, which can cause a serious condition known as polymer fume fever.

Practical and Safer Alternatives to Solvents

Since chemical removal is not a viable option, the focus must shift to methods that work with Teflon's physical properties.

Mechanical Abrasion: The Go-To Method

For almost all practical situations, mechanical removal is the most effective strategy. This involves physically scraping or wearing away the residue.

Methods include using a razor scraper (on flat surfaces), steel wool, sandpaper, or highly abrasive scouring pads. The key is to use physical force to break the residue apart.

Media Blasting: For Industrial Applications

In an industrial context, abrasive blasting (like sandblasting or bead blasting) is a common method. This technique uses a high-pressure stream of abrasive particles to strip the coating from the substrate.

This is a fast and effective method but requires specialized equipment and safety precautions.

Making the Right Choice for Your Goal

Attempting to dissolve Teflon residue is a frustrating exercise that leads to ineffective results and serious safety risks. The correct approach is to bypass chemical solutions entirely.

- If your primary focus is cleaning cookware or a small part: Use mechanical abrasion. Start with a plastic scraper to remove what you can, then move to a more aggressive abrasive like steel wool or a pumice stone.

- If your primary focus is an industrial or manufacturing cleanup: Professional mechanical methods are the standard. Consult with specialists regarding media blasting or controlled, high-temperature thermal decomposition in a specialized facility.

- If you are still considering a chemical solvent: Re-evaluate the risks. The minimal potential benefit is not worth the significant danger to your health and the environment.

Ultimately, overcoming Teflon's resilience requires working with its physical properties, not fighting a losing battle against its chemical stability.

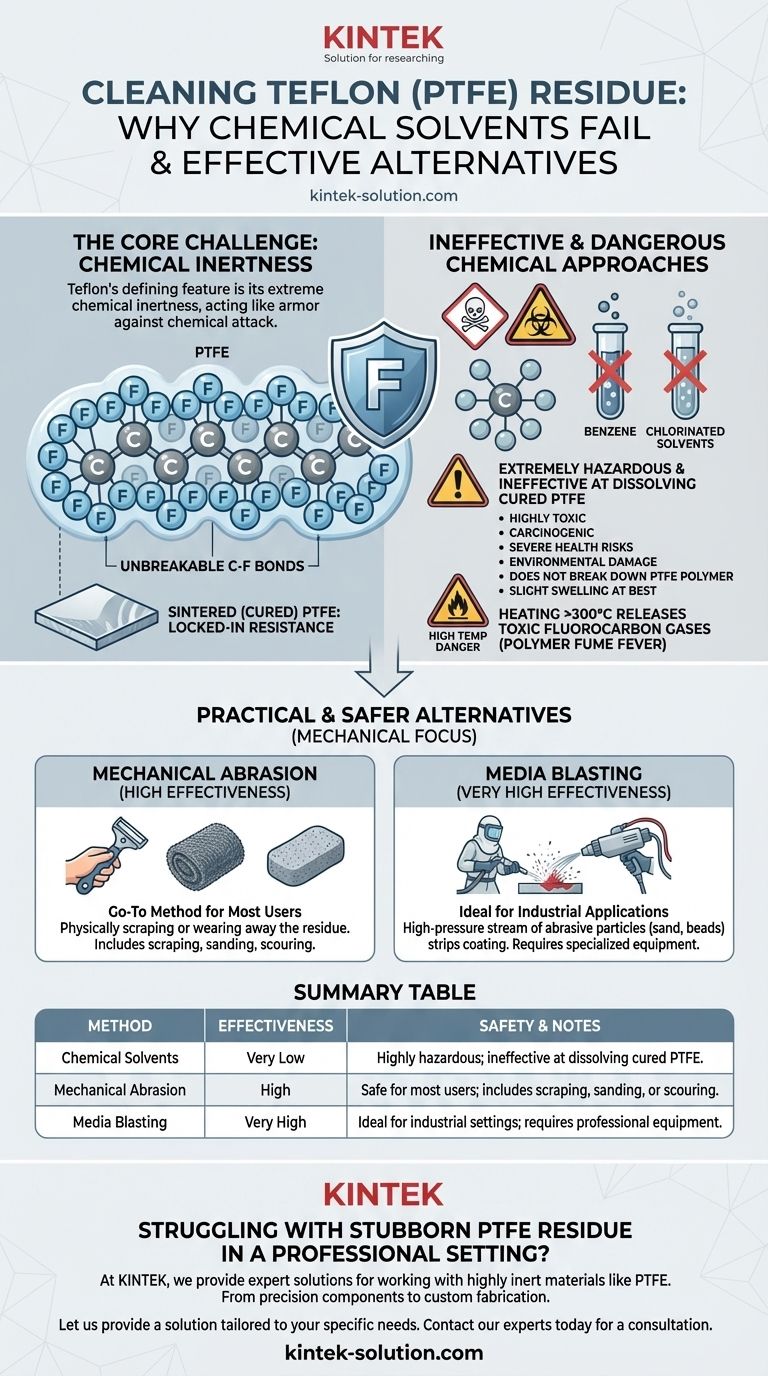

Summary Table:

| Method | Effectiveness | Safety & Notes |

|---|---|---|

| Chemical Solvents | Very Low | Highly hazardous; ineffective at dissolving cured PTFE. |

| Mechanical Abrasion | High | Safe for most users; includes scraping, sanding, or scouring. |

| Media Blasting | Very High | Ideal for industrial settings; requires professional equipment. |

Struggling with stubborn PTFE residue in a professional or industrial setting?

At KINTEK, we understand the challenges of working with highly inert materials like PTFE. We don't just manufacture precision PTFE components (seals, liners, labware, etc.) for the semiconductor, medical, and laboratory industries—we provide expert solutions.

If you're dealing with complex contamination or require custom-fabricated PTFE parts designed for easy maintenance and longevity, our team can help. We prioritize precision production and offer custom fabrication from prototypes to high-volume orders.

Let us provide a solution tailored to your specific needs. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs