There is no standard minimum or maximum size for machining PTFE parts. The feasible dimensions are not defined by universal rules but are instead dictated by the capabilities of a specific machine shop, the size of available raw material stock, and the unique properties of PTFE itself.

The true limitations on PTFE part size are not fixed numbers, but a function of the material's inherent properties. Its softness, high thermal expansion, and tendency to deform under pressure are the critical factors that a machinist must manage, whether the part is large or small.

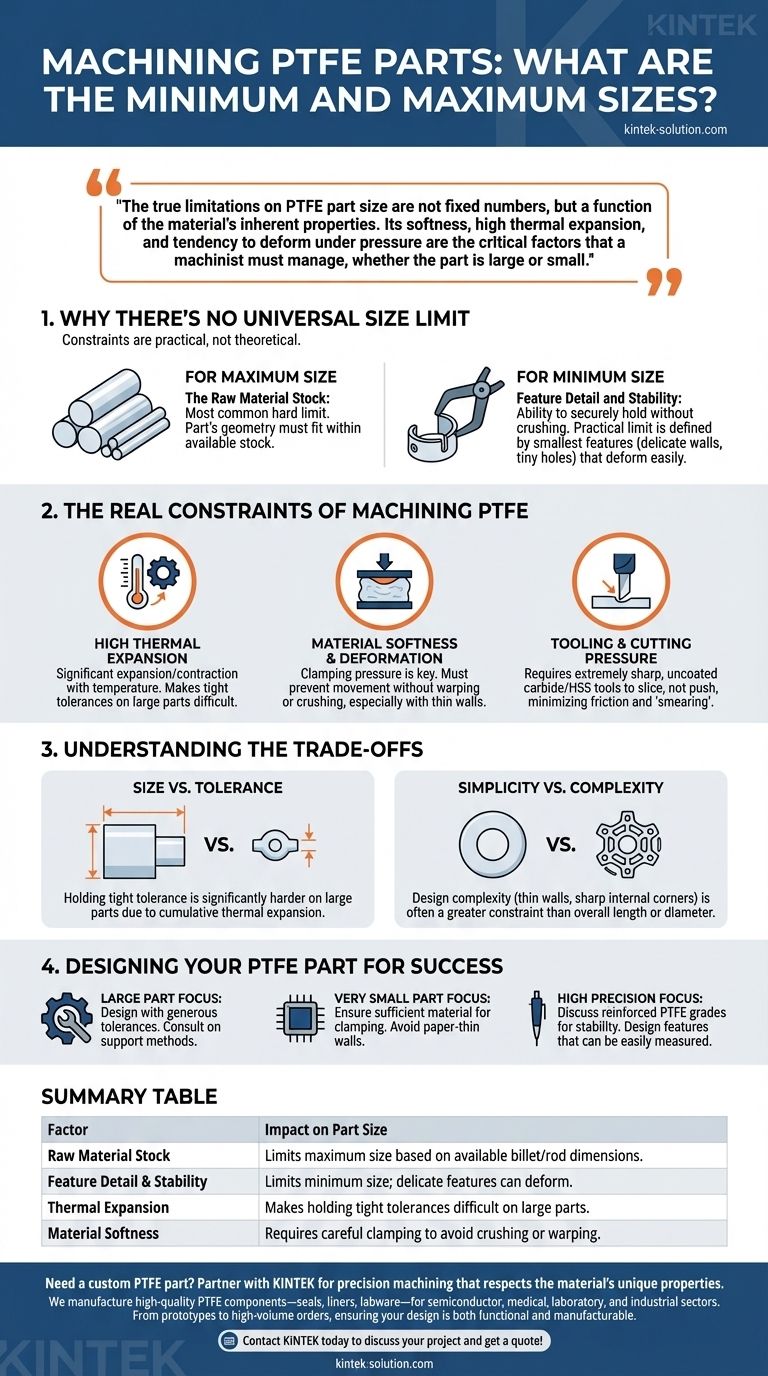

Why There's No Universal Size Limit

Unlike metals, which have more predictable machining behaviors, PTFE presents unique challenges that make size limits a case-by-case determination. The constraints are practical, not theoretical.

For Maximum Size: The Raw Material Stock

The most common hard limit for a large part is the size of the available PTFE billets or rods. While very large custom castings are possible, most machine shops work from standard stock sizes. The part's final geometry must fit within the envelope of a commercially available piece of raw material.

For Minimum Size: Feature Detail and Stability

For small parts, the challenge isn't the overall size but the ability to securely hold the workpiece without crushing it. The practical limit is often defined by the smallest or thinnest feature, such as a delicate wall or a tiny hole, which can easily deform or tear from cutting pressure.

The Real Constraints of Machining PTFE

Understanding the material's behavior is far more important than searching for a specific dimension. These properties dictate the true design for manufacturability limits.

High Thermal Expansion

PTFE expands and contracts significantly with temperature changes. Heat generated during cutting can cause the part to grow, leading to inaccurate final dimensions once it cools. This effect is more pronounced on larger parts, making it difficult to hold tight tolerances across long distances.

Material Softness and Deformation

PTFE is a soft material that can easily be compressed or deformed. A key challenge is clamping pressure. The part must be held firmly enough to prevent movement during machining, but not so tight that it warps or is crushed. This is a primary concern for parts with thin walls or delicate features.

Tooling and Cutting Pressure

Machining PTFE requires an approach focused on slicing, not pushing, the material. This is achieved with extremely sharp, uncoated carbide or high-speed steel tools. These tools minimize friction and cutting pressure, preventing the material from deforming or "smearing" instead of cutting cleanly. The sharpness and geometry of the tool often define the smallest possible internal corner radius or feature detail.

Understanding the Trade-offs

The size of a PTFE part is intrinsically linked to the precision you can realistically achieve.

Size vs. Tolerance

Holding a tight tolerance is significantly harder on a large PTFE part than on a small one. The rule of thumb for a stable, reinforced grade is often +/- .001" per inch of dimension, but this becomes challenging to maintain on large parts due to cumulative thermal expansion effects.

Simplicity vs. Complexity

A simple, large-diameter PTFE washer is far easier to produce than a small, complex component with many intricate features. The design's complexity, especially the presence of thin walls or sharp internal corners, is often a greater constraint than its overall length or diameter.

Designing Your PTFE Part for Success

Instead of focusing on a theoretical size limit, focus on designing a part that accommodates the material's properties.

- If your primary focus is a large part: Design with generous tolerances where possible to account for thermal expansion and consult with your machinist on how to best support the component.

- If your primary focus is a very small part: Ensure your design has sufficient material for secure clamping and avoid features like paper-thin walls that are prone to deformation or tearing.

- If your primary focus is high precision: Discuss using reinforced PTFE grades with your machinist, as they offer greater dimensional stability, and design features that can be easily measured.

Ultimately, the key to a successful PTFE component is a design that respects the material's unique behavior, combined with early communication with your manufacturing partner.

Summary Table:

| Factor | Impact on Part Size |

|---|---|

| Raw Material Stock | Limits maximum size based on available billet/rod dimensions. |

| Feature Detail & Stability | Limits minimum size; delicate features can deform. |

| Thermal Expansion | Makes holding tight tolerances difficult on large parts. |

| Material Softness | Requires careful clamping to avoid crushing or warping. |

Need a custom PTFE part? Partner with KINTEK for precision machining that respects the material's unique properties.

Whether you require a large component with managed tolerances or a small, intricate part that needs secure handling, our expertise in PTFE is your solution. We manufacture high-quality PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring your design is both functional and manufacturable.

Contact KINTEK today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech