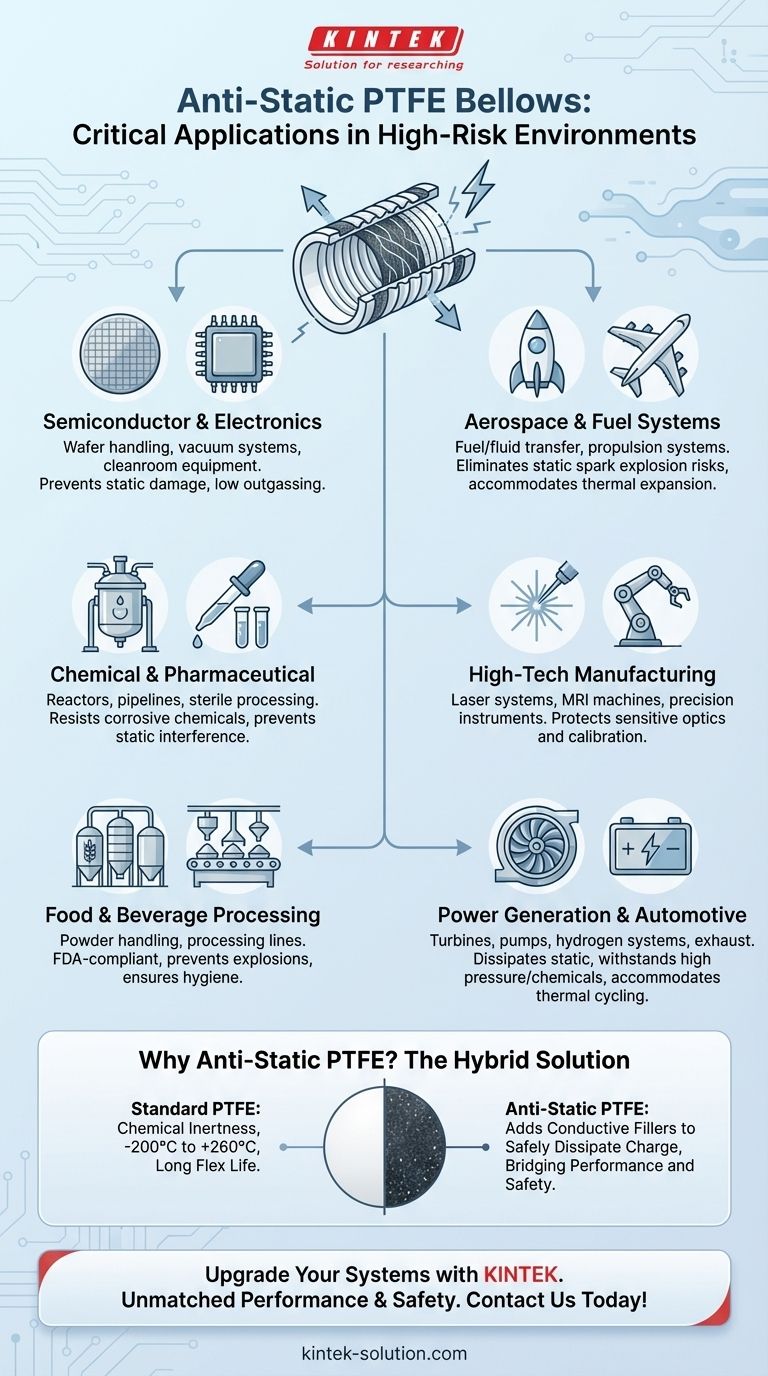

Anti-static PTFE bellows are specialized components designed to address static electricity concerns while leveraging PTFE's inherent properties like chemical resistance, temperature tolerance, and flexibility. They are critical in industries where static discharge could damage sensitive equipment or ignite flammable substances, such as semiconductor manufacturing, aerospace, and chemical processing. Their ability to dissipate static makes them indispensable in cleanrooms, fuel systems, and high-precision environments.

Key Points Explained:

-

Semiconductor and Electronics Manufacturing

- Anti-static PTFE bellows prevent static buildup that could disrupt microchip production or damage delicate components.

- Used in wafer handling, vacuum systems, and cleanroom equipment where even minor static discharge can compromise product quality.

- Their low outgassing properties ensure no contamination of sensitive processes.

-

Aerospace and Fuel Systems

- Critical for fuel/fluid transfer systems in aircraft and spacecraft, where static sparks pose explosion risks.

- PTFE's flexibility and durability accommodate vibration and thermal expansion in dynamic aerospace environments.

- Example: Bellows in rocket propulsion systems or aircraft fuel lines.

-

Chemical and Pharmaceutical Industries

- Resistant to corrosive chemicals (e.g., acids, solvents), making them ideal for reactors, pipelines, and sterile processing.

- Shield sterile areas in pharmaceutical labs from particulate contamination while preventing static interference.

- ptfe balls are also used here for similar anti-static and non-reactive properties.

-

High-Tech Manufacturing (Medical/Laser Equipment)

- Protect sensitive optics in laser systems or MRI machines from static-induced misalignment.

- Used in robotic arms or precision instruments where static could disrupt calibration.

-

Food and Beverage Processing

- FDA-compliant PTFE bellows prevent static in powder handling (e.g., flour, spices) to avoid explosions.

- Non-stick surface ensures hygiene and easy cleaning in processing lines.

-

Power Generation and Water Treatment

- Withstand high-pressure steam or aggressive chemicals in turbines/pumps while dissipating static.

- Prevent static-related corrosion in pipelines carrying purified water or industrial fluids.

-

Automotive and Energy Sectors

- Used in hydrogen fuel cell systems or battery manufacturing, where static control is vital for safety.

- Flexible bellows accommodate thermal cycling in exhaust systems or renewable energy setups.

Why Anti-Static PTFE?

Unlike standard PTFE, anti-static variants incorporate carbon or other conductive fillers to safely dissipate charge without compromising PTFE’s core benefits—chemical inertness, -200°C to +260°C tolerance, and long flex life. This hybrid solution bridges the gap between performance and safety in critical applications.

Have you considered how static dissipation in these bellows compares to traditional grounding methods in high-risk environments? The integration of conductive materials offers a more reliable, maintenance-free solution.

Summary Table:

| Industry | Key Applications | Benefits of Anti-Static PTFE Bellows |

|---|---|---|

| Semiconductor/Electronics | Wafer handling, vacuum systems, cleanroom equipment | Prevents static damage to microchips; low outgassing ensures no contamination |

| Aerospace/Fuel Systems | Fuel transfer, rocket propulsion, aircraft fuel lines | Eliminates explosion risks from static sparks; withstands vibration and thermal expansion |

| Chemical/Pharmaceutical | Reactors, pipelines, sterile processing | Resists corrosive chemicals; prevents static interference in sterile environments |

| High-Tech Manufacturing | Laser systems, MRI machines, robotic arms | Protects sensitive optics/calibration from static disruption |

| Food/Beverage Processing | Powder handling (flour, spices), processing lines | FDA-compliant; prevents explosions and ensures hygiene |

| Power Generation/Water | Turbines, pumps, pipelines for purified water/fluids | Dissipates static in high-pressure/chemical environments; prevents corrosion |

| Automotive/Energy | Hydrogen fuel cells, battery manufacturing, exhaust systems | Ensures safety in energy systems; accommodates thermal cycling |

Upgrade your static-sensitive systems with KINTEK’s precision-engineered anti-static PTFE bellows. Ideal for semiconductor, aerospace, medical, and industrial applications, our bellows combine unmatched chemical resistance, flexibility, and reliable static dissipation. Whether you need standard solutions or custom designs for prototypes or high-volume orders, KINTEK delivers durability and performance. Contact us today to discuss your requirements and explore how our PTFE solutions can enhance your operational safety and efficiency!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- Why is the non-stick surface of PTFE bushings beneficial? For Contamination-Free, Low-Maintenance Performance

- Why are extruded PTFE rods suitable for high-temperature applications? Superior Heat Resistance for Demanding Industries

- What types of fluids are PTFE-lined pipes suitable for transporting? Handle Nearly Any Fluid with Confidence

- Why are PTFE washers resistant to water and moisture? Unlocking the Power of Hydrophobic Sealing

- What efficiency benefits do PTFE lip seals provide in aerospace applications? Reduce Fuel Costs & Boost Reliability

- How does the operating temperature range of PTFE compare to rubber seals? The Ultimate Guide to Extreme-Temperature Sealing

- What makes PTFE suitable for food processing equipment? Ensuring Safety, Efficiency, and Durability

- Why are Teflon-encapsulated O-Rings suitable for medical equipment? Ensure Patient Safety & Chemical Resistance