At its core, extruded PTFE is suitable for high-temperature applications because of its unique molecular structure. Polytetrafluoroethylene (PTFE) possesses a very high melting point and exceptional thermal stability, allowing it to operate continuously at temperatures up to 260°C (500°F) without degrading or losing its essential properties.

The true value of PTFE in high-temperature environments is not just its resistance to melting, but its ability to retain its structural integrity, chemical inertness, and low-friction characteristics when other materials would warp, corrode, or fail.

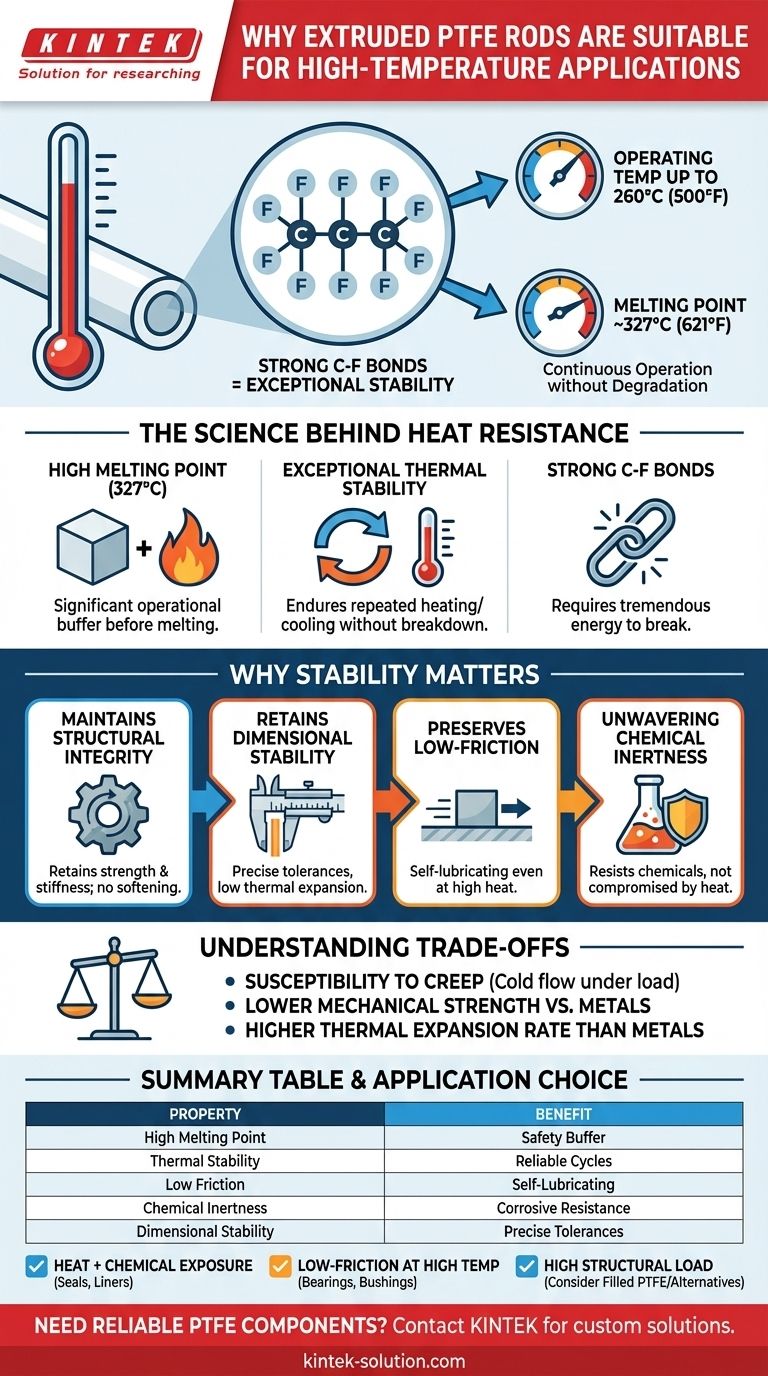

The Science Behind PTFE's Heat Resistance

To understand why PTFE performs so well under thermal stress, we need to look at its fundamental properties. It's a combination of a high melting point and an inherent inability to break down easily.

High Melting Point

PTFE has a remarkably high melting point for a polymer, approximately 327°C (621°F). This gives it a significant operational buffer before it even begins to transition from a solid to a liquid state.

Exceptional Thermal Stability

Thermal stability is a measure of a material's resistance to chemical decomposition at high temperatures. PTFE excels here, meaning it can endure repeated cycles of heating and cooling without its molecular chains breaking down.

This ensures that the material's performance remains consistent and reliable over its service life, even with frequent temperature fluctuations.

Strong Carbon-Fluorine Bonds

The source of PTFE's stability lies in the powerful bonds between its carbon and fluorine atoms. These bonds are among the strongest known in organic chemistry, requiring a tremendous amount of thermal energy to break them apart.

Why Stability at High Temperatures Matters

A high melting point is only part of the story. The reason engineers and designers trust PTFE is its ability to remain a functional, predictable material even when subjected to intense heat.

Maintaining Structural Integrity

Unlike many plastics that soften and lose their shape at elevated temperatures, PTFE rods maintain their strength and stiffness. This makes them ideal for components like seals, bushings, and insulators that must bear loads without deforming.

Retaining Dimensional Stability

PTFE resists significant thermal expansion, especially compared to metals. This dimensional stability ensures that components made from PTFE maintain their precise tolerances, preventing leaks in seals or seizure in bearings.

Preserving Low-Friction Properties

PTFE is known for having one of the lowest coefficients of friction of any solid. Critically, it maintains this self-lubricating property at high temperatures, making it indispensable for non-stick surfaces and high-heat bearings where traditional lubricants would fail.

Unwavering Chemical Inertness

Heat often acts as a catalyst for chemical reactions. PTFE is resistant to nearly all industrial chemicals, and this inertness is not compromised by high temperatures. This makes it the default choice for handling hot, corrosive substances in chemical processing and manufacturing.

Understanding the Trade-offs

While exceptionally capable, PTFE is not without limitations. Acknowledging these is key to successful application design.

Susceptibility to Creep

Under a sustained load, especially at higher temperatures, PTFE can be susceptible to "creep" or cold flow. This is a slow, permanent deformation that must be accounted for in high-load structural designs.

Lower Mechanical Strength vs. Metals

While strong for a polymer, PTFE does not possess the tensile or compressive strength of metals. For applications requiring extreme rigidity or load-bearing capacity, metals or reinforced polymers may be a better fit.

Thermal Expansion Rate

Although dimensionally stable, PTFE's rate of thermal expansion is higher than that of most metals. In designs where PTFE is mated with metal parts, this differential expansion must be carefully managed to avoid stress or failure.

Making the Right Choice for Your Application

Selecting the right material requires aligning its properties with your primary operational goal.

- If your primary focus is combined heat and chemical exposure: PTFE is an unmatched choice for seals, gaskets, and vessel liners in aggressive environments.

- If your primary focus is low-friction performance at high temperatures: It excels in applications like bearings, slide plates, and bushings where self-lubrication is critical.

- If your primary focus is high structural load under heat: You should evaluate filled grades of PTFE (like glass or carbon-filled) or consider alternative high-performance materials if creep is a significant concern.

Ultimately, choosing an extruded PTFE rod is a decision for reliable and predictable performance where thermal stress is a defining challenge.

Summary Table:

| Key Property | Benefit in High-Temperature Applications |

|---|---|

| High Melting Point (~327°C) | Provides a significant safety buffer before melting occurs. |

| Exceptional Thermal Stability | Maintains performance and reliability through repeated heating/cooling cycles. |

| Retains Low Friction | Self-lubricating properties persist where traditional lubricants fail. |

| Unwavering Chemical Inertness | Resists corrosive substances even at elevated temperatures. |

| Dimensional Stability | Maintains precise tolerances with lower thermal expansion than metals. |

Need reliable PTFE components for your high-temperature application?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication ensures you get the exact solution, from prototypes to high-volume orders, that delivers consistent performance under thermal stress.

Contact our experts today to discuss how our PTFE solutions can enhance your project's reliability and efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How are PTFE seals enhanced for mechanical applications? Boost Durability & Performance with Filled PTFE

- How can dimensional stability be maintained in machined PTFE parts? Master Precision Machining & Stress Relief

- What type of valves are most suitable for highly corrosive or chemical industries? The Definitive Guide to PTFE Lined Butterfly Valves

- What is the maximum pressure that PTFE piston seals can handle? Understand the Full System of Limits

- How can virgin PTFE be prepared for bonding? Achieve a Permanent, High-Strength Bond

- What are the primary applications of PTFE-lined ball valves? Control Corrosive & High-Purity Fluids

- What makes PTFE O-rings suitable for sealing applications? Unmatched Chemical & Thermal Resistance

- What additional construction applications exist for PTFE beyond slide bearings? Leverage PTFE for Thermal Breaks & Washers