In short, PTFE O-rings are exceptional sealing materials due to their unique combination of extreme chemical inertness, a very wide operational temperature range, and an incredibly low coefficient of friction. This makes them highly durable and reliable in environments where conventional elastomeric seals would quickly fail.

The core reason for PTFE's sealing performance lies in its molecular structure. The powerful carbon-fluorine bonds create a chemically stable and thermally resistant material, making it a "go-to" solution for the most demanding applications, from aggressive chemical processing to cryogenic systems.

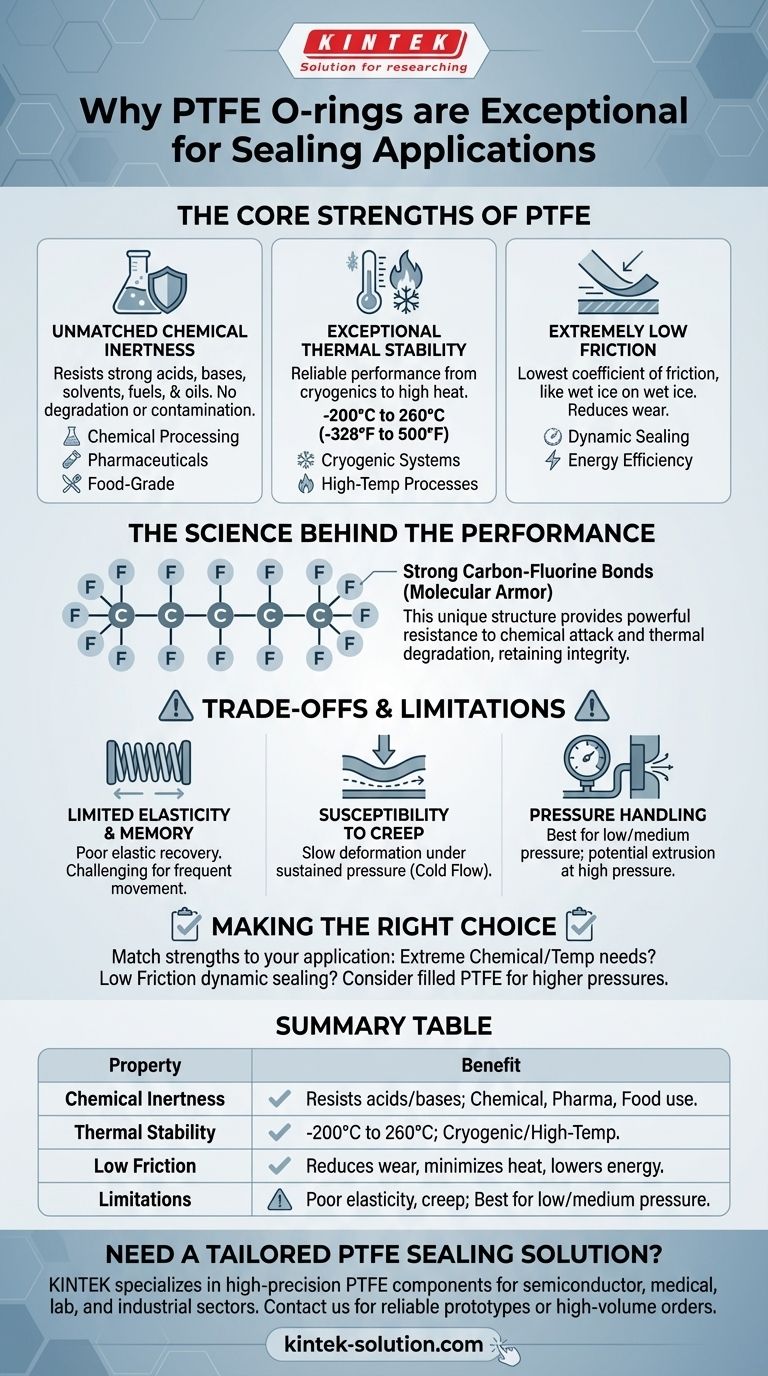

The Core Strengths of PTFE for Sealing

The suitability of Polytetrafluoroethylene (PTFE) is not based on a single property, but on the synergy of three key characteristics that make it uniquely robust.

Unmatched Chemical Inertness

PTFE offers outstanding resistance to a vast range of chemicals. It is virtually unaffected by strong acids, bases, solvents, fuels, and oils.

This inertness ensures the seal maintains its integrity and does not degrade, swell, or contaminate the system, which is critical in chemical processing, pharmaceuticals, and food-grade applications.

Exceptional Thermal Stability

PTFE seals perform reliably across an extremely wide temperature spectrum, typically from -200°C to 260°C (-328°F to 500°F).

This allows it to be used in applications involving cryogenic liquids or high-temperature processes where standard rubber or elastomeric O-rings would become brittle or melt.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "non-stick" or low-friction surface is a major advantage.

In dynamic sealing applications with moving parts, this property reduces wear and tear on both the seal and the equipment, minimizes heat generation from friction, and lowers the energy required for operation.

The Science Behind the Performance

The remarkable properties of PTFE are a direct result of its unique molecular structure, which was discovered by accident in 1938.

The Power of the Carbon-Fluorine Bond

PTFE's structure consists of a long chain of carbon atoms completely shielded by a sheath of fluorine atoms.

The bond between carbon and fluorine is exceptionally strong and stable. This molecular armor is what gives the material its powerful resistance to chemical attack and thermal degradation.

The Impact on Sealing Integrity

Because of this structure, the material is highly resilient. It retains its mechanical properties and flexibility even when subjected to extreme heat, cold, or harsh chemical exposure.

Its softness allows it to deform slightly and fill in microscopic imperfections between surfaces, creating a tight and effective seal against leaks.

Understanding the Trade-offs and Limitations

While powerful, PTFE is not a universal solution. An expert advisor must highlight the engineering trade-offs inherent in the material.

Limited Elasticity and "Memory"

Unlike traditional rubber O-rings, PTFE is not a true elastomer. It has poor "elastic memory," meaning that once compressed, it does not readily return to its original shape.

This makes installation more challenging and means it may not be suitable for applications requiring the seal to accommodate significant or frequent movement and resealing.

Susceptibility to Creep (Cold Flow)

Under sustained pressure, especially at elevated temperatures, PTFE can be prone to creep, or "cold flow." This is a slow, continuous deformation of the material.

In high-pressure static seals, this can eventually lead to a loss of sealing force and potential leakage over time.

Pressure Handling

The references note that PTFE is effective for low and medium-pressure applications. Its softness, which is an advantage for conformity, becomes a liability under very high pressures where the material could be extruded from the sealing groove.

Making the Right Choice for Your Application

Selecting the correct sealing material requires a clear understanding of your operational demands. PTFE excels where others fail, but it's crucial to match its strengths to your specific problem.

- If your primary focus is extreme chemical resistance or temperature range: PTFE is one of the best choices available, providing reliability where almost any other polymer would degrade.

- If your primary focus is dynamic sealing in a low-friction environment: PTFE's non-stick properties make it ideal for reducing wear and energy consumption in moving systems.

- If your primary focus is high-pressure sealing or repeated assembly: You may need to consider modified PTFE compounds (filled with glass, carbon, or bronze) or explore alternative materials with better elastic memory and creep resistance.

Ultimately, understanding both the exceptional strengths and the specific limitations of PTFE is the key to engineering a successful and reliable sealing system.

Summary Table:

| Key Property | Benefit for Sealing Applications |

|---|---|

| Chemical Inertness | Resists strong acids, bases, solvents; ideal for chemical processing, pharmaceuticals, and food-grade use. |

| Thermal Stability | Performs reliably from -200°C to 260°C, suitable for cryogenic and high-temperature processes. |

| Low Friction | Reduces wear in dynamic seals, minimizes heat generation, and lowers operational energy. |

| Limitations | Poor elasticity, susceptibility to creep under pressure; best for low/medium-pressure static or dynamic seals. |

Need a PTFE sealing solution tailored to your demanding application?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures reliable performance in extreme conditions.

Contact us today to discuss your specific requirements and let our team provide a solution that guarantees sealing integrity and longevity.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is it important to understand the different types of PTFE lip seals? Ensure 40,000+ Hours of Reliability

- In which industries are PTFE mill-type envelope gaskets applied? Ensure Leak-Free Sealing in Demanding Environments

- What makes PTFE seals suitable for extreme temperature applications? Unmatched Stability from -200°C to +260°C

- What role do PTFE expansion bellows play in vibration absorption? Isolate Equipment to Prevent System Damage

- When might additional lubrication be needed for PTFE applications? Understand the exceptions to the rule.

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance

- What types of applications commonly use PTFE rotary seals? Solve Extreme Chemical, Temperature, and Speed Challenges

- Are fibrous fillers better than particulate fillers in PTFE? Optimize Your PTFE Component Performance