Beyond its well-known use in slide bearings, PTFE is highly valued in modern construction for its role as high-performance thermal breaks, specialized washers, and critical component separators. These applications leverage the same unique properties that make it essential for bearings: an incredibly low coefficient of friction, chemical inertness, and excellent thermal stability.

The core principle to understand is that PTFE's value in construction extends beyond simply accommodating large-scale movement. Its fundamental properties make it a premier material for isolating structural components—thermally, electrically, and chemically—while managing friction at connection points.

Why PTFE Is More Than Just a Bearing Material

To grasp PTFE's expanded role, you must first understand its fundamental characteristics. These properties are not just beneficial for slide bearings; they are the reason it can solve other complex engineering challenges in construction.

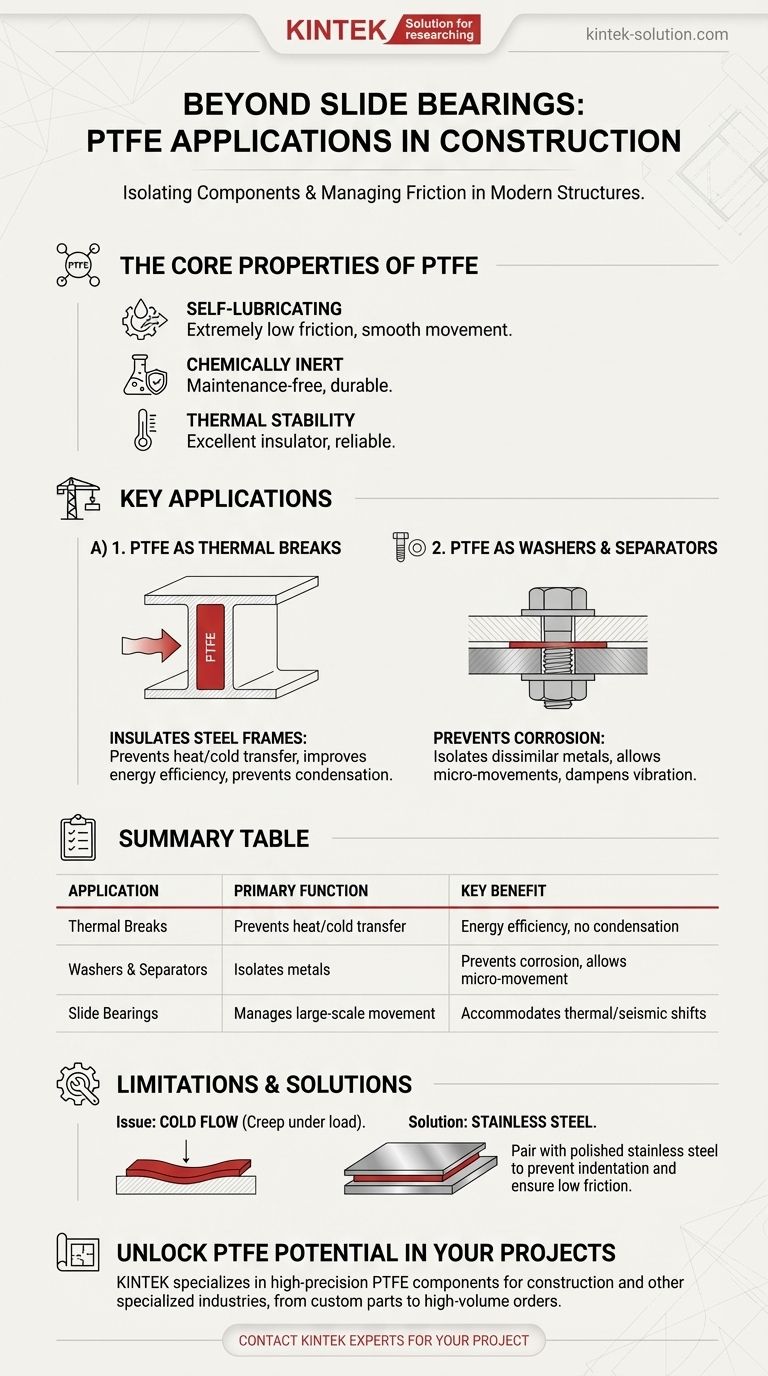

The Core Properties

PTFE (Polytetrafluoroethylene) offers a combination of benefits that are rare to find in a single material. It is self-lubricating, with one of the lowest coefficients of friction of any solid, ensuring smooth, predictable movement between surfaces.

Furthermore, it is almost completely chemically inert and does not degrade over time, making it a maintenance-free component for the life of the structure.

Practicality in the Field

PTFE components are designed for straightforward integration into standard construction workflows. Installation methods often include simple bolting, tack-welding, or mortar embedment, which are familiar to construction crews.

This versatility simplifies the installation process and reduces the need for specialized equipment or training compared to more complex mechanical systems.

Key Applications Beyond Bearings

While slide bearings manage large, obvious movements, PTFE's other applications solve more subtle but equally important problems within a structure.

PTFE as Thermal Breaks

A thermal break is a material with low thermal conductivity placed between two conductive materials (like steel beams) to prevent heat or cold transfer.

PTFE's inherent properties make it an excellent thermal insulator. Using it at connection points in a building's steel frame can significantly reduce thermal bridging, improving energy efficiency and preventing condensation issues.

PTFE as Washers and Separators

In bolted connections, particularly between dissimilar metals, PTFE washers serve a critical function. They act as a separator to prevent galvanic corrosion.

Their low-friction surface also allows for slight rotational adjustments during assembly without galling or damaging the connected steel members. As separators, thin PTFE sheets can isolate entire components, dampening vibration and accommodating minor deflections.

Understanding the Trade-offs and Limitations

Like any engineering material, PTFE is not without its limitations. Understanding these is crucial for its proper specification and long-term performance.

The Issue of Cold Flow (Indentation)

Standard PTFE can be susceptible to "cold flow," or creep, where it slowly deforms under a sustained, concentrated load. If a PTFE surface is paired with another PTFE surface, the lower member may indent over time.

This indentation can increase friction and cause premature wear during movement.

The Stainless Steel Solution

The industry-standard solution to prevent cold flow is to pair the PTFE surface with a much harder mating surface, typically polished stainless steel.

The hard, smooth steel distributes the load evenly across the PTFE, preventing indentation and ensuring a consistently low-friction interface for the life of the connection.

Protection During Construction

The performance of PTFE is highly dependent on its surface integrity. It is critical that during installation, the PTFE surface is protected from weld spatter, paint spray, and metal filings. Any contamination or damage can compromise its low-friction properties.

How to Apply This to Your Project

Choosing the right application depends entirely on the specific engineering problem you are trying to solve.

- If your primary focus is managing large thermal expansion or seismic movement: The classic PTFE slide bearing remains the definitive solution.

- If your primary focus is improving a building's energy efficiency: Specify PTFE thermal breaks at key steel-to-steel connection points to minimize thermal bridging.

- If your primary focus is preventing corrosion or binding in bolted connections: Utilize PTFE washers and separators to isolate dissimilar materials and allow for micro-movements.

By understanding PTFE's core properties, you can leverage it not just for large-scale movement, but for thermal, chemical, and frictional isolation throughout your entire structural design.

Summary Table:

| Application | Primary Function | Key Benefit |

|---|---|---|

| Thermal Breaks | Prevents heat/cold transfer in steel frames | Improves energy efficiency, prevents condensation |

| Washers & Separators | Isolates dissimilar metals, prevents corrosion | Allows micro-movements, dampens vibration |

| Slide Bearings | Manages large-scale structural movement | Accommodates thermal expansion and seismic activity |

Unlock the Full Potential of PTFE in Your Construction Projects

PTFE's unique properties—like its incredibly low coefficient of friction, chemical inertness, and excellent thermal stability—make it an indispensable material for solving complex challenges in modern construction, from thermal breaks to corrosion prevention.

KINTEK specializes in manufacturing high-precision PTFE components—including custom seals, liners, labware, and specialized construction parts—for the semiconductor, medical, laboratory, industrial, and other specialized industries. We prioritize precision production and offer custom fabrication from prototypes to high-volume orders.

Let us help you enhance your structural designs with reliable, high-performance PTFE solutions. Contact our experts today to discuss your specific project requirements and receive a tailored quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments