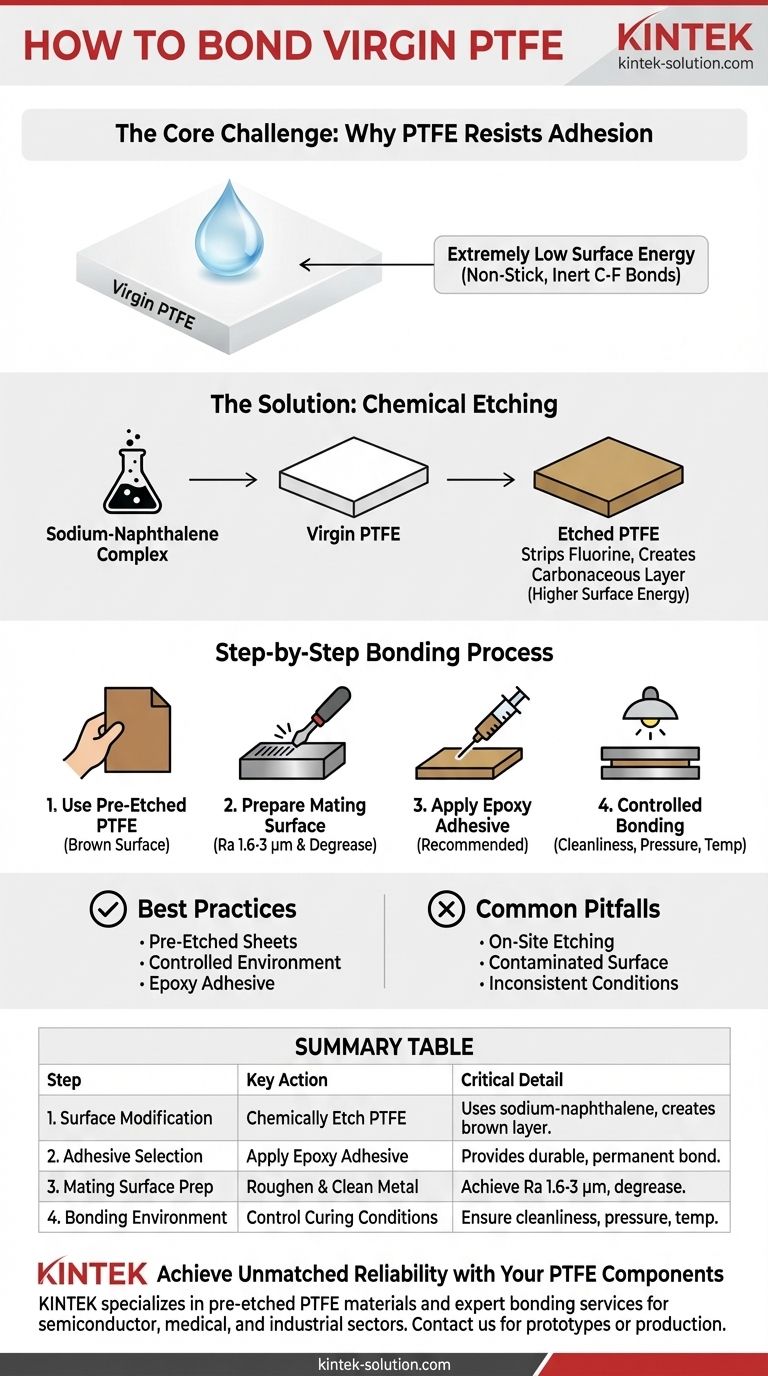

To prepare virgin PTFE for bonding, you must alter its chemically inert, non-stick surface. This is achieved through a process called chemical etching, which modifies the molecular structure of the PTFE, turning its surface brown and making it receptive to industrial adhesives.

The core challenge with bonding PTFE is its extremely low surface energy, which prevents adhesives from wetting and gripping the surface. The only reliable solution is to use a chemical etchant that breaks the fluorine-carbon bonds, creating a new, bondable surface layer.

The Core Challenge: Why PTFE Resists Adhesion

The Nature of Polytetrafluoroethylene (PTFE)

Polytetrafluoroethylene, or PTFE, is renowned for its chemical inertness and extremely low coefficient of friction. These properties make it an excellent non-stick material.

This non-stick nature is a direct result of its molecular structure, which consists of strong, stable bonds between carbon and fluorine atoms.

The Problem of Low Surface Energy

For an adhesive to work, it must be able to "wet" the surface, meaning it needs to spread out and make intimate contact. Virgin PTFE has a very low surface energy, which causes liquids—including adhesives—to bead up rather than spread.

Without surface modification, a strong adhesive bond to virgin PTFE is physically impossible.

The Solution: Chemical Etching Explained

What is Chemical Etching?

Chemical etching is a process that uses a reactive chemical solution to change the surface of the PTFE. The specific formulations are often proprietary but typically involve a sodium-naphthalene complex.

This etchant strips fluorine atoms from the polymer backbone, leaving behind a carbonaceous layer that has a much higher surface energy. This new layer is what adhesives can securely grip.

The Visual Indicator: The Brown Surface

The most obvious sign of a successfully etched PTFE surface is a change in color from its native milky white to a uniform tan or dark brown.

This brown surface is the bondable layer. It is crucial that this layer is not mechanically abraded or contaminated before the adhesive is applied.

The Recommended Adhesive

Once the PTFE is etched, it can be bonded using a range of standard industrial adhesives.

Epoxy adhesives are highly recommended for this application. They offer excellent sheer strength and create a durable, permanent bond with the modified PTFE surface.

Best Practices for a Reliable Bond

Use Pre-Etched PTFE Sheets

For consistency and safety, the most reliable approach is to purchase PTFE sheets that have been professionally etched on one or both sides.

This eliminates the need to handle hazardous etching chemicals and ensures a uniformly prepared surface, which is critical for bond strength.

Prepare the Mating Surface

The surface you are bonding the PTFE to must also be properly prepared. For metals, this involves creating a specific surface roughness.

A roughness between Ra = 1.6 µm and Ra = 3 µm is ideal. After machining or grinding, the surface must be thoroughly degreased with a solvent like acetone to remove all contaminants.

Common Pitfalls to Avoid

The Risks of On-Site Application

Attempting to etch PTFE on-site is not recommended for most applications. The etchants are hazardous, and the process requires strict control over conditions to be effective.

Inconsistent etching will lead to weak spots and premature bond failure.

The Importance of Controlled Conditions

Successful bonding requires more than just a prepared surface. The entire process depends on strictly controlled conditions of cleanliness, pressure, and temperature during the adhesive curing cycle.

This is why factory-controlled bonding is almost always superior to field or site bonding.

Making the Right Choice for Your Application

- If your primary focus is reliability and performance: Always specify pre-etched PTFE from a reputable supplier and have the bonding performed in a controlled manufacturing environment.

- If you are bonding to a prepared metal substrate: Ensure the metal surface is both mechanically roughened to the correct specification and chemically cleaned before applying the epoxy.

- If you are prototyping or in R&D: Using pre-etched sheets will allow you to isolate other variables and focus on joint design and adhesive performance.

Ultimately, understanding that PTFE's surface must be chemically transformed, not just cleaned or abraded, is the key to achieving a successful bond.

Summary Table:

| Step | Key Action | Critical Detail |

|---|---|---|

| 1. Surface Modification | Chemically Etch PTFE | Uses a sodium-naphthalene complex to create a brown, bondable layer. |

| 2. Adhesive Selection | Apply Epoxy Adhesive | Provides excellent sheer strength for a durable, permanent bond. |

| 3. Mating Surface Prep | Roughen & Clean Metal | Achieve Ra 1.6-3 µm surface roughness and degrease with acetone. |

| 4. Bonding Environment | Control Curing Conditions | Ensure cleanliness, pressure, and temperature for optimal strength. |

Achieve Unmatched Reliability with Your PTFE Components

Successfully bonding PTFE is critical for performance in demanding applications. At KINTEK, we specialize in the precise fabrication of PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, and industrial sectors.

We provide pre-etched PTFE materials and expert bonding services in our controlled environment, eliminating the risks of on-site preparation. This ensures your assemblies deliver maximum strength and longevity.

Let us help you solve your toughest bonding challenges. Contact KINTEB today to discuss your project requirements, from prototypes to high-volume production.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining