For selecting valves in highly corrosive or chemical industries, the most suitable and widely trusted option is the PTFE lined butterfly valve. This specific design is engineered to provide superior resistance to chemical attack and ensures a tight seal, preventing dangerous leaks of aggressive media.

The critical insight is not just the valve type (butterfly), but the protective lining material (PTFE). This combination creates a chemically inert barrier that isolates the valve's structural body from corrosive fluids, delivering safety and longevity in a single, efficient package.

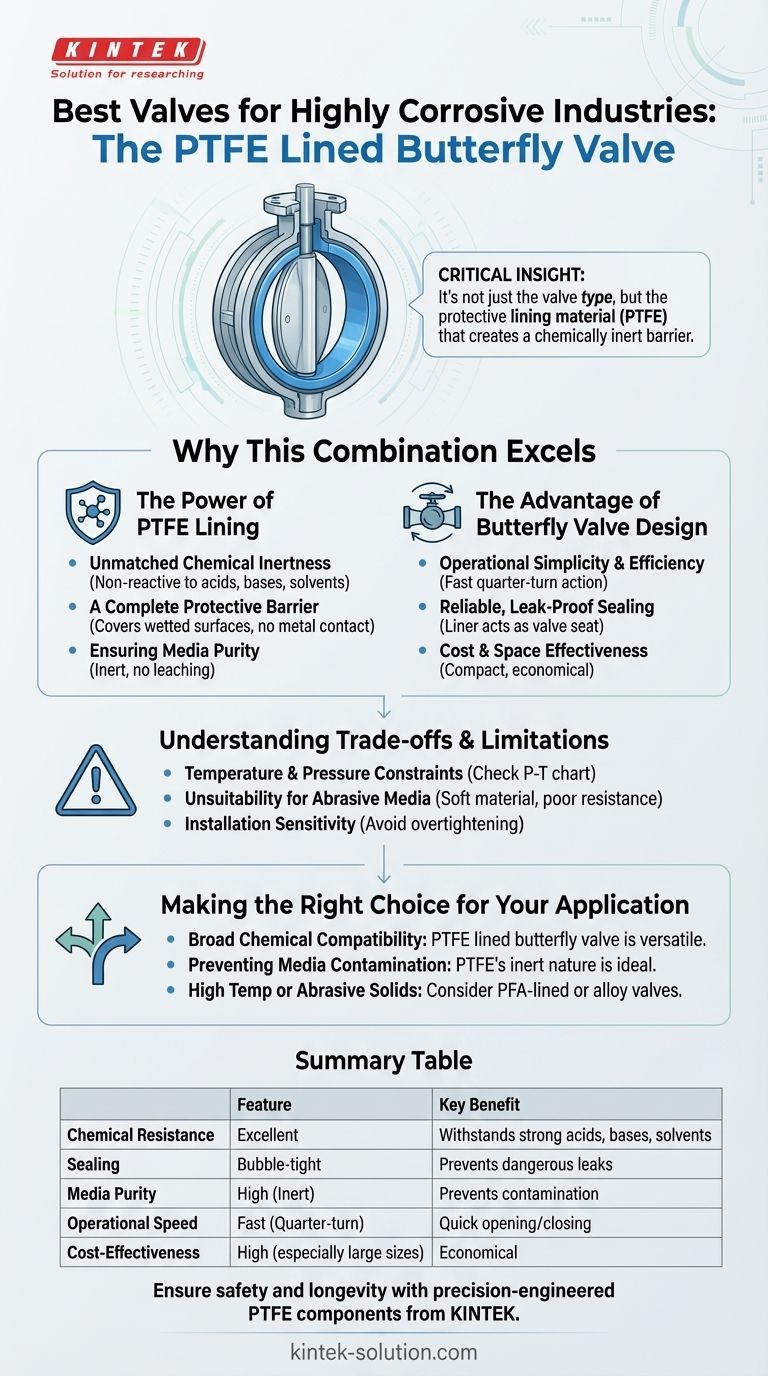

Why This Combination Excels

The effectiveness of a PTFE lined butterfly valve comes from the perfect synergy between its material science and its mechanical design. Each aspect solves a critical problem posed by corrosive environments.

The Power of PTFE Lining

Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer, and its properties make it the gold standard for chemical applications.

Unmatched Chemical Inertness PTFE is renowned for being non-reactive. It can withstand a vast spectrum of aggressive chemicals, including strong acids, bases, and solvents, without degrading.

A Complete Protective Barrier The lining completely covers the wetted internal surfaces of the valve. This means the corrosive process fluid only ever touches the PTFE liner and the PTFE-encapsulated disc, never the metal valve body (typically cast iron or stainless steel).

Ensuring Media Purity Because PTFE is inert, it does not leach materials into the process fluid. This prevents contamination, which is crucial not only for safety but also for applications requiring high purity.

The Advantage of Butterfly Valve Design

The butterfly valve's simple yet robust design complements the protective qualities of the PTFE liner perfectly.

Operational Simplicity and Efficiency A butterfly valve operates with a disc that rotates 90 degrees in the flow path. This quarter-turn action allows for very fast opening and closing.

Reliable, Leak-Proof Sealing In this design, the PTFE liner also functions as the valve seat. When the disc closes, it presses firmly into the resilient liner, creating a bubble-tight seal that is essential for containing hazardous chemicals.

Cost and Space Effectiveness Compared to other valve types like lined ball or plug valves, butterfly valves are generally lighter, more compact, and more cost-effective, especially in larger pipe sizes.

Understanding the Trade-offs and Limitations

While exceptional, PTFE lined butterfly valves are not a universal solution. An expert advisor must highlight the operational boundaries to ensure proper application.

Temperature and Pressure Constraints

PTFE has distinct temperature and pressure limits that must be respected. At very high temperatures, the material can soften, and its pressure-holding capability decreases. Always verify the manufacturer's P-T (Pressure-Temperature) chart.

Unsuitability for Abrasive Media

PTFE is a relatively soft material. It offers poor resistance to abrasive particles or slurries, which can quickly erode the liner and compromise the seal, leading to failure.

Installation Sensitivity

The integrity of the seal depends heavily on proper installation. Overtightening flange bolts can damage the PTFE liner at the sealing faces, creating a primary leak path before the valve even enters service.

Making the Right Choice for Your Application

Your final decision should be based on the specific demands of your process.

- If your primary focus is broad chemical compatibility: A PTFE lined butterfly valve is the most versatile and cost-effective choice for a wide range of corrosive fluids within its operational limits.

- If your primary focus is preventing media contamination: The inert nature of the PTFE lining is ideal, guaranteeing that the valve itself will not alter the purity of your process fluid.

- If you are dealing with high temperatures or abrasive solids: You must look beyond this valve type and consider options like PFA-lined valves for higher temperatures or specialized alloy valves for abrasive service.

Ultimately, matching the valve's material and design capabilities to your specific operational needs is the key to ensuring a safe, reliable, and long-lasting installation.

Summary Table:

| Feature | PTFE Lined Butterfly Valve | Key Benefit |

|---|---|---|

| Chemical Resistance | Excellent | Withstands strong acids, bases, and solvents |

| Sealing | Bubble-tight | Prevents dangerous leaks of aggressive media |

| Media Purity | High (Inert) | Prevents contamination of the process fluid |

| Operational Speed | Fast (Quarter-turn) | Allows for quick opening and closing |

| Cost-Effectiveness | High (especially in large sizes) | More economical than other lined valve types |

Ensure the safety and longevity of your chemical processes with precision-engineered PTFE components from KINTEK.

As specialists in high-performance PTFE fabrication for the semiconductor, medical, laboratory, and industrial sectors, we understand the critical demands of handling corrosive media. Our PTFE lined butterfly valves are manufactured with a focus on precision and durability, providing a reliable, cost-effective solution for your most challenging applications.

We offer custom fabrication services, from initial prototypes to high-volume production runs, ensuring a perfect fit for your specific needs.

Contact KINTEK today to discuss your valve requirements and let our expertise enhance your operational safety and efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability