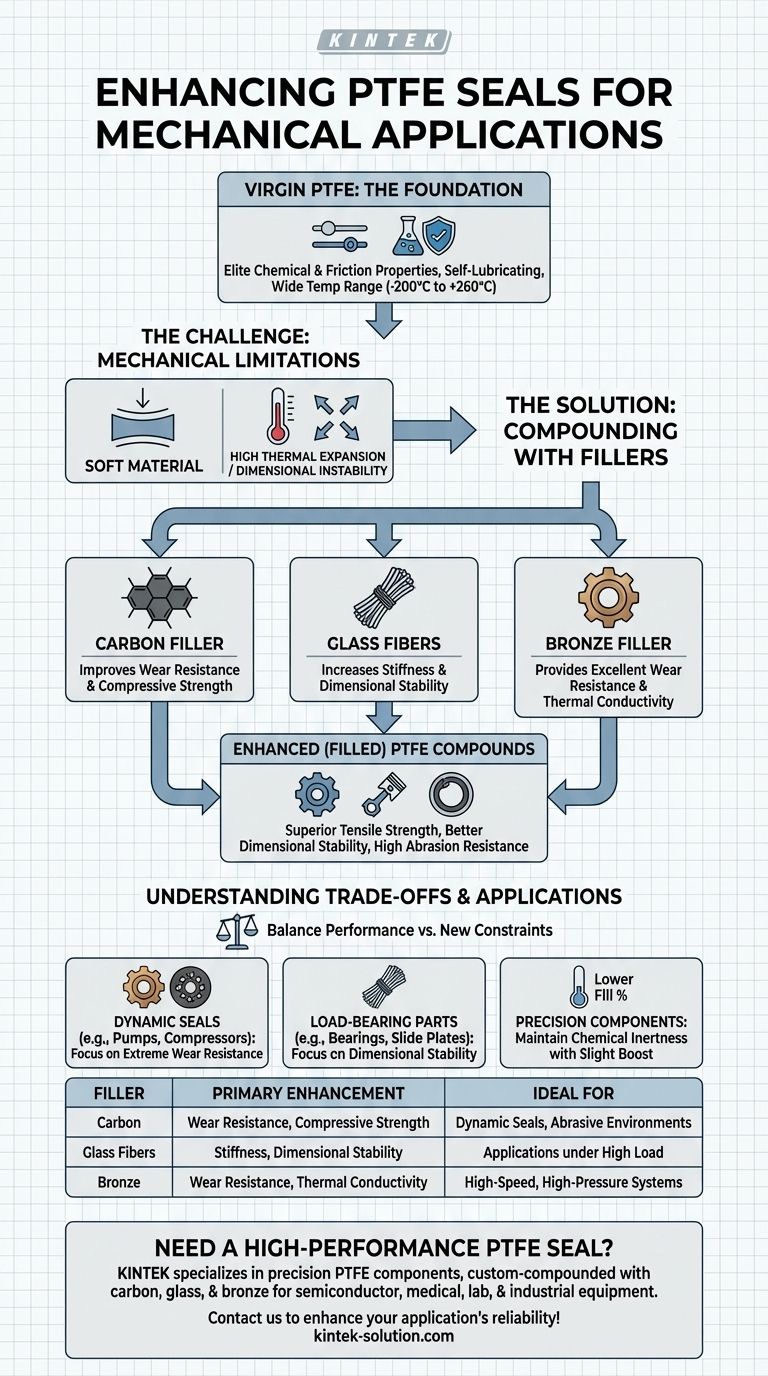

At its core, Polytetrafluoroethylene (PTFE) is enhanced for demanding mechanical applications by compounding it with specialized fillers. These additives are integrated directly into the PTFE material to improve its physical properties, overcoming the inherent softness of its virgin form.

The central challenge with pure PTFE is a conflict between its elite chemical and friction properties and its relatively poor mechanical strength. The solution is to create PTFE compounds, where fillers like carbon, glass, or bronze are added to grant the material the necessary durability, dimensional stability, and wear resistance required for high-performance seals.

The Challenge of Virgin PTFE in Mechanical Systems

Unmatched Surface and Chemical Properties

Pure PTFE is renowned for its extremely low coefficient of friction, which allows parts to slide with minimal resistance. This self-lubricating characteristic reduces wear, heat, and energy consumption in machinery.

It also possesses outstanding chemical inertness and can withstand a vast range of temperatures, from -200°C to +260°C.

The Inherent Mechanical Weakness

Despite these benefits, virgin PTFE is a relatively soft material.

It exhibits high thermal expansion and is sensitive to dimensional changes, which can be a significant drawback in precision mechanical applications like pumps, compressors, and gearboxes.

Enhancing Performance: The Role of Fillers

What Are Fillers?

Fillers are reinforcing materials mixed with the base PTFE polymer before it is formed into a seal or component. This process creates a new composite material, often called a "filled PTFE" or "PTFE compound."

Key Benefits of Filled PTFE

Adding fillers fundamentally alters the material's mechanical capabilities.

The primary improvements include significantly increased tensile strength, better dimensional stability under load and temperature changes, and superior abrasion resistance.

Common Filler Materials

While many fillers exist, some of the most common used to enhance PTFE seals include:

- Carbon: Improves wear resistance and compressive strength.

- Glass Fibers: Increase stiffness and dimensional stability.

- Bronze: Provides excellent wear resistance and thermal conductivity.

Understanding the Trade-offs

No Single "Best" Compound

Enhancing one property with a filler can sometimes modify another. The selection of a filler is always a matter of balancing performance requirements for a specific application.

Impact on Core Properties

For example, while bronze dramatically improves wear resistance, it does not share the near-universal chemical inertness of pure PTFE.

Similarly, adding glass fibers increases stiffness but can be abrasive to softer metal mating surfaces. Choosing the right filler means understanding both the problem you are solving and any new constraints you might be introducing.

Common Applications for Enhanced PTFE

High-Demand Sealing

Filled PTFE compounds are critical in equipment where seals face high pressure, velocity, or abrasive conditions. You will commonly find them in pumps, high-performance valves, and compressors.

Bearings and Sliding Parts

The combination of low friction and high strength makes filled PTFE ideal for self-lubricating bearings, piston rings, and slide plates. These components reduce maintenance needs and improve the efficiency of sliding mechanical actions.

Making the Right Choice for Your Application

Selecting the correct PTFE formulation depends entirely on the primary challenge you need to overcome.

- If your primary focus is extreme wear resistance in a dynamic seal: A bronze-filled or carbon-filled PTFE compound is likely the best starting point.

- If your primary focus is dimensional stability under load: A glass-fiber-filled PTFE will provide the necessary stiffness and resistance to deformation.

- If your primary focus is maintaining chemical inertness with a slight boost in mechanical properties: A lower percentage fill of a specialized material may be required.

Ultimately, enhancing PTFE with fillers transforms it from an excellent specialty material into a robust engineering workhorse.

Summary Table:

| Filler Type | Primary Enhancement | Ideal For |

|---|---|---|

| Carbon | Wear Resistance, Compressive Strength | Dynamic seals, abrasive environments |

| Glass Fibers | Stiffness, Dimensional Stability | Applications under high load |

| Bronze | Wear Resistance, Thermal Conductivity | High-speed, high-pressure systems |

Need a high-performance PTFE seal for your specific mechanical application?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom-compounded seals enhanced with fillers like carbon, glass, and bronze. Whether you require superior wear resistance, dimensional stability, or a balance of properties for semiconductor, medical, laboratory, or industrial equipment, our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a seal that delivers optimal performance and longevity.

Contact us today to discuss your requirements and let our solutions enhance your application's reliability!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE's low friction coefficient benefit mechanical systems? Boost Efficiency & Extend Lifespan

- What are the primary properties of PTFE rod? Unlock Extreme Performance for Demanding Applications

- How does PTFE improve bearing performance? Achieve Low-Friction, Maintenance-Free Operation

- How can limited compressibility of PTFE gaskets be managed? Master Precision Sealing for Flawless Performance

- How do PTFE and NBR oil seals compare in terms of flexibility and installation? Choose the Right Seal for Your Application

- What are the reasons for intentionally designing a wide contact area in PTFE sealing elements? Boost Reliability & Lifespan

- How is MoS2 (Moly) typically combined in PTFE applications? Synergistic Fillers for Low Friction

- What is the development history of PTFE O-ring seals? From Simple Shapes to High-Performance Seals