At its core, the non-stick surface of a Polytetrafluoroethylene (PTFE) bushing is beneficial because it prevents other materials—from industrial contaminants to process media—from adhering to it. This fundamental property leads directly to reduced contamination, simplified cleaning, and more consistent operational performance over the life of the component.

The non-stick nature of PTFE is not merely a convenience; it is a critical engineering feature. It ensures the bushing remains free from performance-degrading buildup, which translates into lower friction, reduced maintenance costs, and a significantly longer service life for the entire assembly.

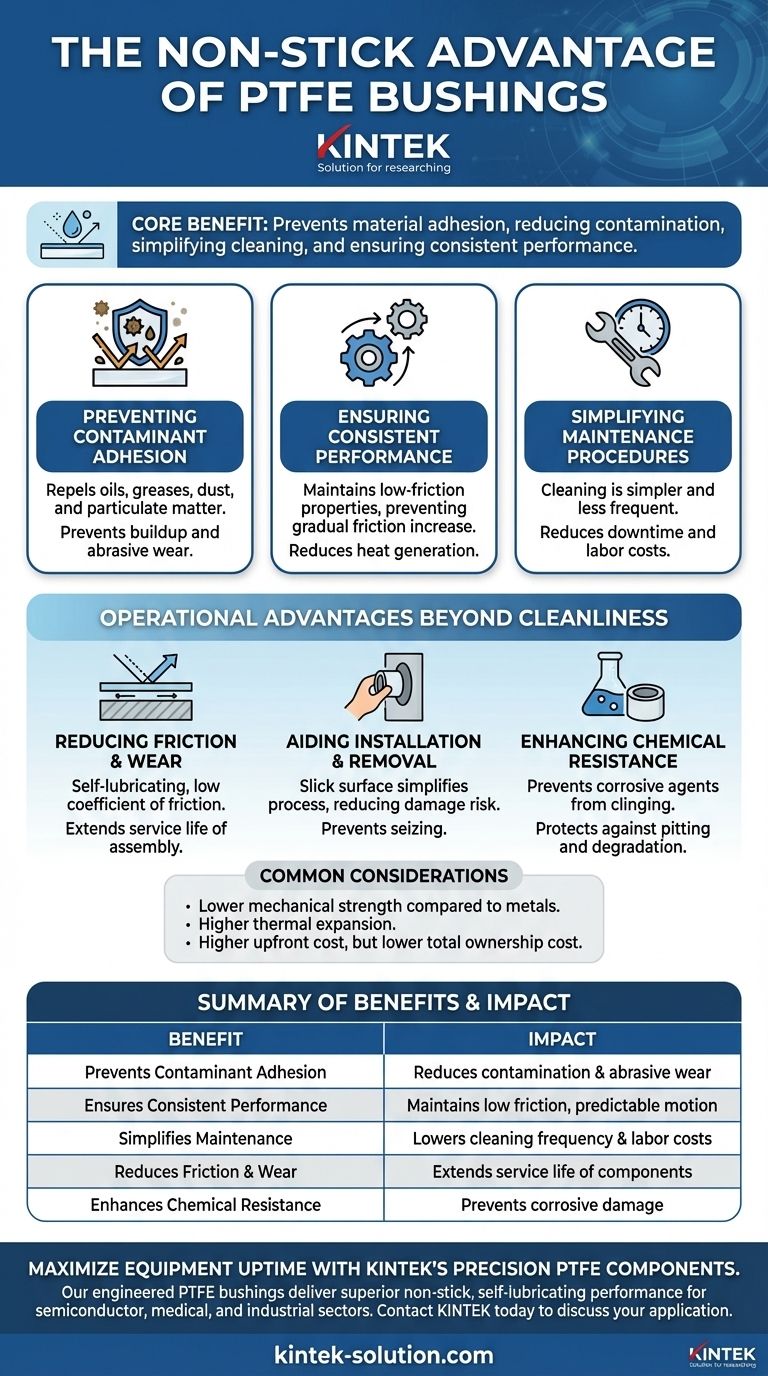

The Core Function of a Non-Stick Surface

The term "non-stick" describes a surface with very low surface energy, making it difficult for other substances to bond to it. In the context of a bushing, this has several profound implications for mechanical systems.

Preventing Contaminant Adhesion

The primary benefit is the prevention of buildup. The surface actively repels common contaminants like oils, greases, dust, and other particulate matter.

This self-cleaning characteristic is crucial in environments where debris could otherwise accumulate on the bushing, turning it into an abrasive component or impeding motion.

Ensuring Consistent Performance

By preventing the accumulation of foreign materials, the bushing's low-friction properties remain constant. There is no gradual increase in friction that would otherwise occur as debris builds up.

This consistency is vital for applications requiring smooth, predictable motion and efficiency, as it helps reduce heat generation even at high loads and velocities.

Simplifying Maintenance Procedures

Because contaminants do not stick, cleaning procedures are vastly simplified and often less frequent. In many cases, the system's normal operation is enough to keep the surface clear.

This significantly reduces maintenance downtime and the associated labor costs, contributing to a lower total cost of ownership.

Operational Advantages Beyond Cleanliness

The non-stick property works in concert with PTFE's other unique characteristics to deliver a higher level of performance than many traditional bushing materials.

Reducing Friction and Wear

The non-stick surface is intrinsically linked to PTFE's self-lubricating nature and extremely low coefficient of friction.

Without the ability for micro-particles to adhere and cause abrasive wear, the bushing maintains its integrity and protects the shaft it supports, extending the application's service life.

Aiding Installation and Removal

The slick, non-stick surface simplifies the installation process. The bushing can be pressed into its housing with less force, reducing the risk of damage to either the bushing or the component.

Similarly, removal is easier because the bushing is less likely to seize or gall within its housing over time.

Enhancing Chemical Resistance

In applications involving harsh chemicals, the non-stick surface ensures that corrosive agents do not cling to the bushing. This enhances PTFE's already excellent chemical resistance, preventing pitting or degradation that might otherwise occur.

Common Pitfalls and Considerations

While highly beneficial, PTFE is not the ideal solution for every scenario. Understanding its limitations is key to using it effectively.

Lower Mechanical Strength

Compared to metallic bushings (like bronze), PTFE is a softer material. It can be more susceptible to deformation or "creep" under very high, sustained static loads.

Higher Thermal Expansion

PTFE has a higher coefficient of thermal expansion than most metals. This must be accounted for during the design phase to ensure proper operating clearance is maintained across the application's full temperature range.

Cost vs. Value

The upfront cost of a PTFE bushing can be higher than that of some traditional plastic or metal alternatives. The true value is realized in its maintenance-free operation, extended component life, and system reliability.

Making the Right Choice for Your Application

Selecting a PTFE bushing is a strategic decision based on solving specific operational challenges.

- If your primary focus is cleanliness and contamination control (e.g., food, pharma): The non-stick surface is essential for preventing material buildup and can be specified to meet FDA requirements.

- If your primary focus is reducing maintenance in a harsh or inaccessible environment: The combination of non-stick, self-lubricating, and chemical-resistant properties provides a true "fit-and-forget" solution.

- If your primary focus is smooth, efficient, low-friction motion: The non-stick surface guarantees that the bushing's low coefficient of friction remains consistent, ensuring predictable performance.

Ultimately, the non-stick property of PTFE is a foundational feature that enables its superior reliability, cleanliness, and long-term value in demanding applications.

Summary Table:

| Benefit | Impact |

|---|---|

| Prevents Contaminant Adhesion | Reduces system contamination and abrasive wear |

| Ensures Consistent Performance | Maintains low friction and predictable motion |

| Simplifies Maintenance | Lowers cleaning frequency, downtime, and labor costs |

| Reduces Friction & Wear | Extends service life of the bushing and supported shaft |

| Enhances Chemical Resistance | Prevents corrosive agents from clinging and causing damage |

Maximize your equipment's uptime and reliability with KINTEK's precision PTFE components.

Our PTFE bushings, seals, liners, and custom labware are engineered to deliver the superior non-stick, self-lubricating, and chemical-resistant performance detailed in this article. We serve the semiconductor, medical, laboratory, and specialized industrial sectors, providing custom fabrication from prototypes to high-volume orders.

Let us provide a solution that reduces your maintenance costs and extends component life.

Contact KINTEK today to discuss your specific application requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs