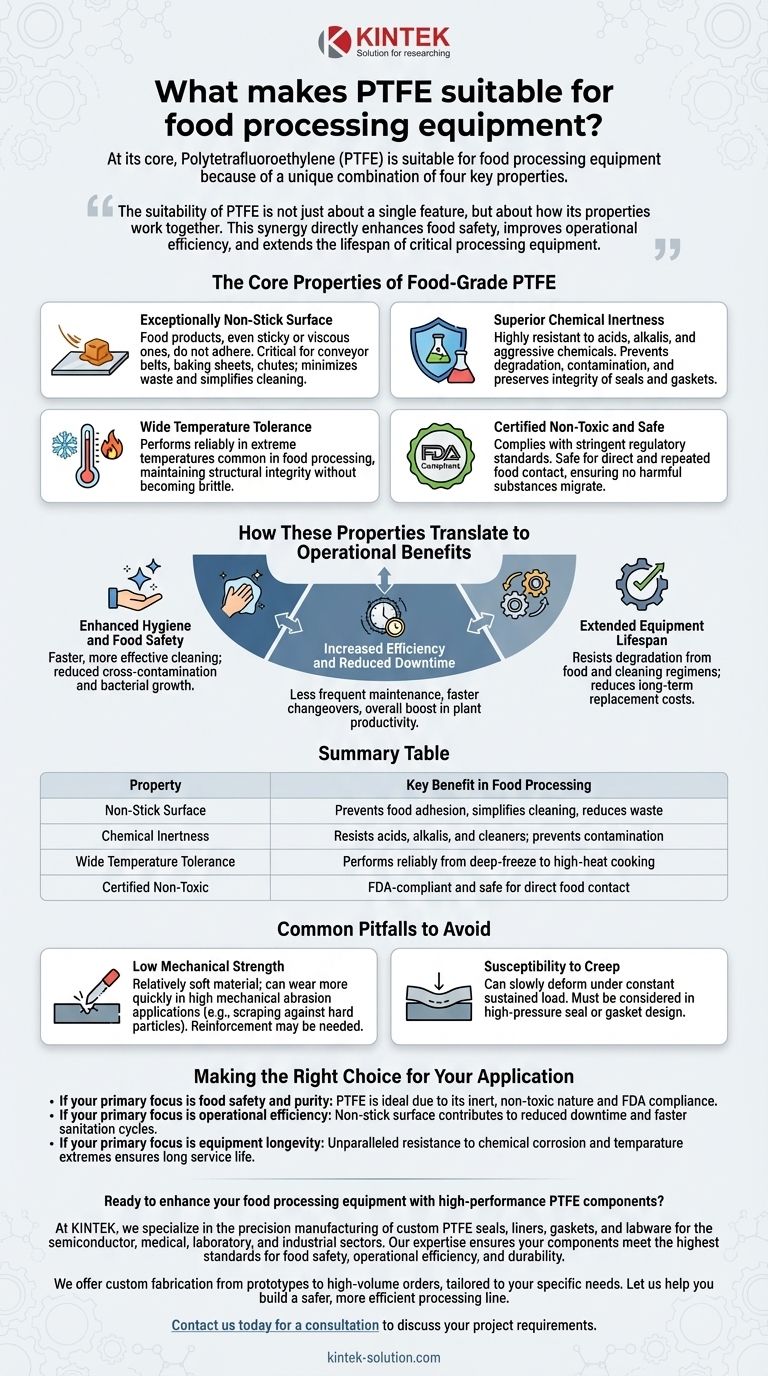

At its core, Polytetrafluoroethylene (PTFE) is suitable for food processing equipment because of a unique combination of four key properties. Its surface is exceptionally non-stick, it is chemically inert to virtually all foods and cleaning agents, it maintains stability across a vast temperature range, and it is certified non-toxic and safe for direct food contact.

The suitability of PTFE is not just about a single feature, but about how its properties work together. This synergy directly enhances food safety, improves operational efficiency, and extends the lifespan of critical processing equipment.

The Core Properties of Food-Grade PTFE

Understanding why PTFE is so prevalent requires looking at its fundamental material characteristics. Each one solves a specific challenge inherent in food and beverage production.

Exceptionally Non-Stick Surface

The surface of PTFE is one of the most slippery materials known, meaning food products, even sticky or viscous ones, do not adhere to it.

This property is critical for conveyor belts, baking sheets, and chutes. It ensures the easy release of products like confectionery and baked goods, which minimizes waste and simplifies cleaning.

Superior Chemical Inertness

PTFE's strong atomic structure makes it highly resistant to corrosion from acidic substances like tomato sauce, alkaline cleaning solutions, and other aggressive chemicals.

This ensures that the material itself does not break down, degrade, or leach into the food, preventing contamination and preserving the integrity of seals, gaskets, and valves over time.

Wide Temperature Tolerance

PTFE performs reliably in extreme temperature environments common in food processing, from high-heat baking and cooking processes to deep-freezing applications.

It maintains its structural integrity and performance without becoming brittle or degrading, making it a dependable choice for components used throughout the entire production line.

Certified Non-Toxic and Safe

Materials used in food processing must meet stringent regulatory standards. Food-grade PTFE is non-toxic and complies with standards set by bodies like the FDA.

This certification provides the necessary assurance that the material is safe for direct and repeated contact with consumable products, ensuring no harmful substances migrate into the food supply.

How These Properties Translate to Operational Benefits

The material science of PTFE directly creates tangible advantages in the demanding environment of a food processing plant.

Enhanced Hygiene and Food Safety

Because food residue and microbes cannot easily stick to PTFE's surface, cleaning is faster and more effective.

This ease of cleaning, combined with its resistance to harsh sanitizing chemicals, drastically reduces the risk of cross-contamination and bacterial growth, leading to a safer final product.

Increased Efficiency and Reduced Downtime

Equipment with PTFE components requires less frequent and less intensive maintenance. The non-stick surface reduces the need for manual scraping, and its durability means fewer component failures.

This translates directly to less production downtime, faster changeovers between product runs, and an overall boost in plant productivity.

Extended Equipment Lifespan

Components like gaskets, seals, and valve seats are often the first to fail due to chemical attack or temperature stress.

By using PTFE, these parts resist degradation from both the food products and the cleaning regimens. This extends the service life of the equipment and reduces long-term replacement costs.

Common Pitfalls to Avoid

While PTFE is an exceptional material, it is not a universal solution. Understanding its limitations is key to successful application.

Low Mechanical Strength

PTFE is a relatively soft material. In applications with high mechanical abrasion, such as scraping against hard or sharp particles, it can wear more quickly than harder plastics or metals.

For this reason, it is sometimes reinforced with other materials like glass fiber or carbon to improve its wear resistance and rigidity for more demanding mechanical roles.

Susceptibility to Creep

Under a constant, sustained load (a phenomenon known as "creep"), PTFE can slowly deform over time.

This must be considered in the design of high-pressure seals or gaskets. Proper engineering and component design can mitigate this, but it is a fundamental property of the material.

Making the Right Choice for Your Application

Selecting the right material requires aligning its strengths with your most critical operational goals.

- If your primary focus is food safety and purity: PTFE is an ideal choice due to its inert, non-toxic nature and compliance with FDA regulations.

- If your primary focus is operational efficiency: The non-stick, easy-to-clean surface of PTFE directly contributes to reduced downtime and faster sanitation cycles.

- If your primary focus is equipment longevity: PTFE's unparalleled resistance to chemical corrosion and temperature extremes ensures a long service life for critical components.

Ultimately, leveraging PTFE correctly is about using its distinct advantages to create a safer, more efficient, and more reliable food processing environment.

Summary Table:

| Property | Key Benefit in Food Processing |

|---|---|

| Non-Stick Surface | Prevents food adhesion, simplifies cleaning, reduces waste |

| Chemical Inertness | Resists acids, alkalis, and cleaners; prevents contamination |

| Wide Temperature Tolerance | Performs reliably from deep-freeze to high-heat cooking |

| Certified Non-Toxic | FDA-compliant and safe for direct food contact |

Ready to enhance your food processing equipment with high-performance PTFE components?

At KINTEK, we specialize in the precision manufacturing of custom PTFE seals, liners, gaskets, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your components meet the highest standards for food safety, operational efficiency, and durability.

We offer custom fabrication from prototypes to high-volume orders, tailored to your specific needs. Let us help you build a safer, more efficient processing line.

Contact us today for a consultation to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How do spring-energized PTFE seals contribute to energy efficiency? Minimize Friction and Reduce Energy Waste

- What makes expanded PTFE gaskets resistant to corrosion? Unmatched Chemical Inertness for Harsh Environments

- What are spring-energized PTFE seals? The Ultimate Sealing Solution for Extreme Environments

- What is the pressure resistance capability of PTFE oil seals compared to conventional oil seals? Discover the High-Performance Advantage

- What are the different types of PTFE packing available? Choose the Right Seal for Your Application

- What industries use custom PTFE parts and for what purposes? Solve Critical Challenges with High-Performance Materials

- What types of media are suitable for PTFE Bellow Mechanical Seals? Sealing the Most Aggressive Chemicals

- How do PTFE and graphite packing compare in terms of corrosion resistance? Selecting the Right Material for Your Application