In essence, a spring-energized PTFE seal is a high-performance sealing device composed of a precision-machined polymer jacket, typically made of Polytetrafluoroethylene (PTFE), and a metallic spring energizer. The spring provides a constant, outward mechanical force on the PTFE jacket's sealing lips. This creates a highly reliable and resilient seal, particularly in applications where traditional elastomeric seals like O-rings would fail due to chemical attack, extreme temperatures, or high pressure.

While conventional seals rely on the inherent elasticity of their material, spring-energized PTFE seals use a mechanical spring to guarantee a consistent sealing force. This design principle makes them the definitive solution for the most demanding industrial environments where performance and reliability are non-negotiable.

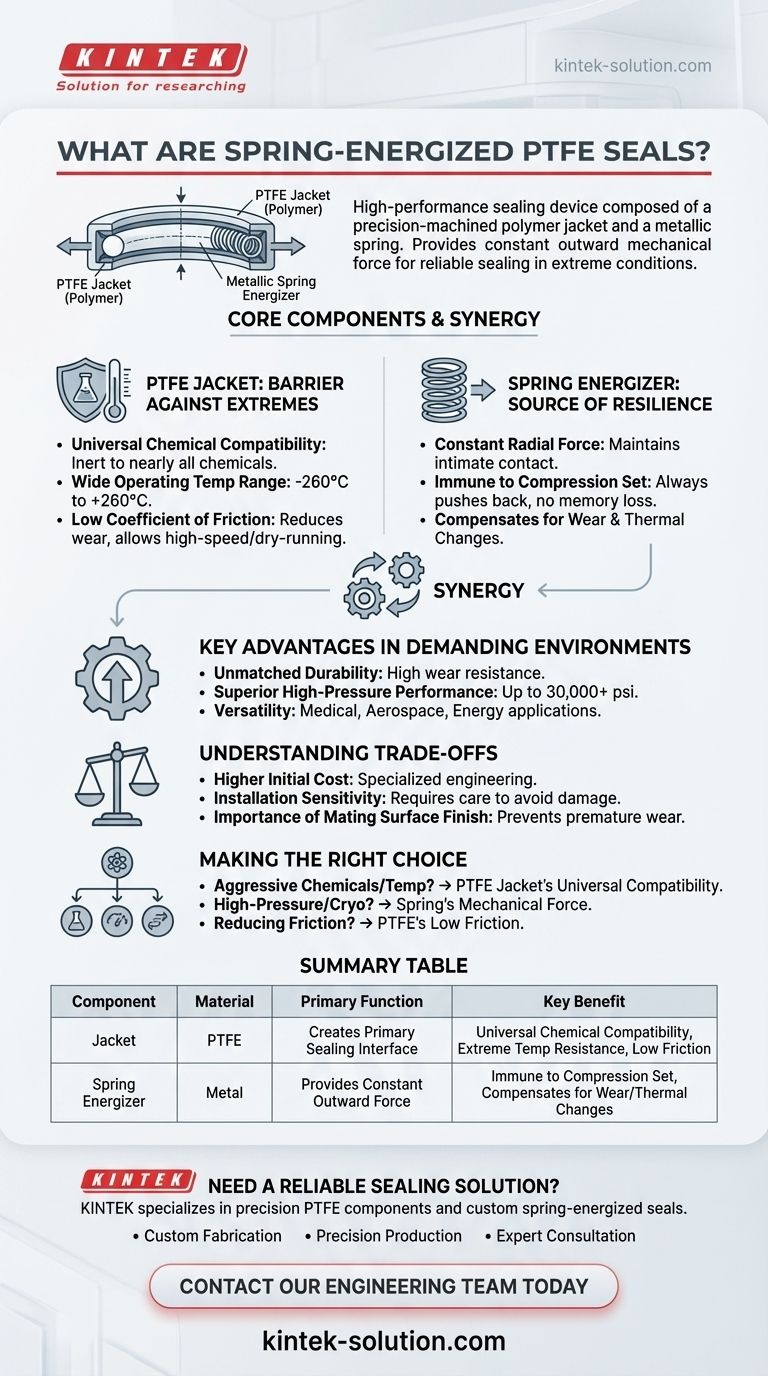

The Two Core Components of Performance

To understand why these seals are so effective, you must look at how their two primary components work in synergy. The design separates the material properties (the jacket) from the mechanical force (the spring).

The PTFE Jacket: A Barrier Against Extremes

The outer jacket is the seal's primary interface with the operating environment. Using PTFE, often called the "King of Plastics," provides a set of elite characteristics.

PTFE offers universal chemical compatibility, remaining inert when exposed to nearly all industrial chemicals, solvents, acids, and bases.

It also has an exceptionally wide operating temperature range, maintaining its properties in cryogenic conditions as low as -260°C (-425°F) and at high temperatures exceeding 260°C (500°F).

Finally, PTFE has an extremely low coefficient of friction. This inherent lubricity reduces wear and heat generation in dynamic applications, allowing for high-speed service and even dry-running conditions.

The Spring Energizer: The Source of Resilience

The internal spring is the engine of the seal. It provides the constant radial force needed to maintain intimate contact between the PTFE jacket and the sealing surfaces.

This mechanical force ensures a tight seal at very low pressures and compensates for factors that compromise other seal types. These factors include thermal expansion and contraction, material creep, and jacket wear over time.

Most critically, the spring makes the seal immune to compression set and aging embrittlement. Unlike an elastomer that loses its "memory" and flattens over time, the spring will always push back, guaranteeing a long and reliable service life.

Key Advantages in Demanding Environments

The combination of the PTFE jacket and the spring energizer delivers a unique set of capabilities that solve critical engineering challenges.

Unmatched Durability

These seals are highly wear-resistant, making them ideal for reciprocating or rotary applications where friction would quickly destroy a lesser seal. This durability significantly reduces maintenance cycles and associated costs.

Superior Performance Under Pressure

The spring energizer provides the force needed to maintain seal integrity in high-pressure applications, with some designs rated for over 30,000 psi. The system pressure itself also acts on the seal, further increasing the sealing force.

Versatility Across Industries

From medical devices requiring resistance to harsh sterilization processes to aerospace and energy applications involving extreme temperatures and pressures, these seals provide a reliable solution where contamination or leakage is not an option.

Understanding the Trade-offs

No single solution is perfect for every scenario. To make an informed decision, it's critical to understand the considerations associated with these high-performance components.

Higher Initial Cost

Spring-energized PTFE seals are specialized components engineered for extreme conditions. Their manufacturing process is more complex than that of a simple molded O-ring, resulting in a higher per-unit cost.

Installation Sensitivity

While robust in operation, the relatively rigid nature of the PTFE jacket means care must be taken during installation to avoid scratching or gouging the sealing lips. Unlike a flexible elastomer, it cannot be simply stretched over threads or sharp corners without proper tools and procedures.

Importance of Mating Surface Finish

To achieve optimal performance and seal life, the hardware's mating surfaces (the shaft and bore) must have a high-quality surface finish. A rough surface can cause premature wear on the PTFE jacket and create potential leak paths.

Making the Right Choice for Your Application

Selecting the right seal requires aligning its capabilities with your primary engineering goal.

- If your primary focus is handling aggressive chemicals or extreme temperatures: The universal compatibility and vast operating range of spring-energized PTFE seals make them the default choice where elastomers would chemically degrade or fail.

- If your primary focus is high-pressure or cryogenic service: The mechanical force from the spring ensures a reliable seal integrity that is independent of material memory, which is compromised at these extremes.

- If your primary focus is reducing friction in high-speed or unlubricated systems: The exceptionally low coefficient of friction of the PTFE jacket minimizes wear and energy consumption, extending the life of the entire assembly.

By understanding this synergy between the polymer jacket and the mechanical spring, you can confidently specify a sealing solution built for resilience in your most critical applications.

Summary Table:

| Component | Material | Primary Function | Key Benefit |

|---|---|---|---|

| Jacket | PTFE (Polytetrafluoroethylene) | Creates the primary sealing interface | Universal chemical compatibility, extreme temperature resistance (-260°C to +260°C), low friction |

| Spring Energizer | Metal (typically) | Provides constant outward mechanical force | Immune to compression set, compensates for wear and thermal changes, ensures reliable sealing |

Need a reliable sealing solution for your extreme application?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom spring-energized seals for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your seals are built to withstand aggressive chemicals, extreme temperatures, and high pressures.

We offer:

- Custom Fabrication: From prototypes to high-volume orders

- Precision Production: Ensuring optimal performance in your critical applications

- Expert Consultation: Helping you select the right seal design for your specific needs

Let us provide the resilient sealing solution your project demands. Contact our engineering team today to discuss your requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications