The corrosion resistance of expanded PTFE gaskets is rooted in the fundamental chemical inertness of the base polytetrafluoroethylene (PTFE) polymer. This material is inherently non-reactive to the vast majority of industrial chemicals, including strong acids and alkalis, because of its incredibly stable molecular structure which prevents chemical attack.

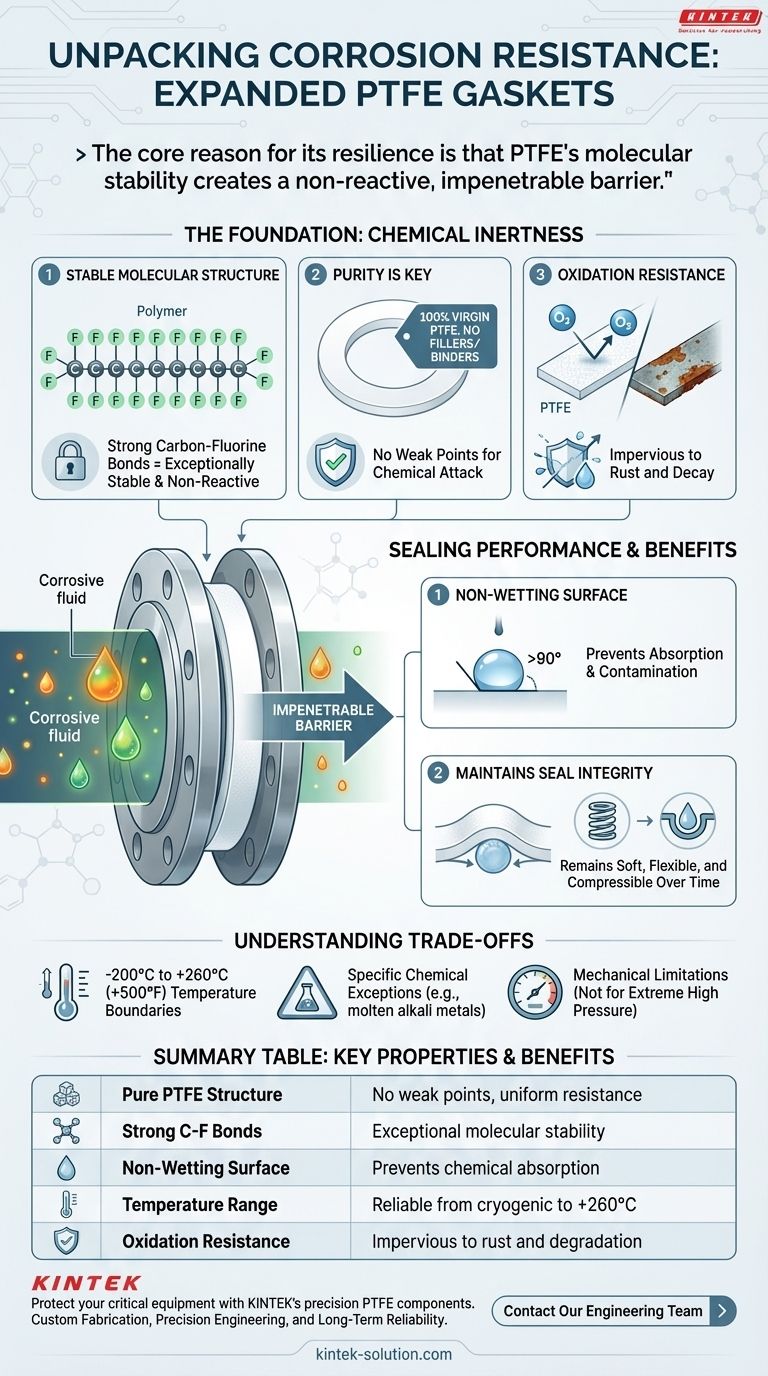

The core reason for its resilience is that PTFE's molecular stability creates a non-reactive, impenetrable barrier. Corrosive chemicals cannot find a pathway to attack the gasket material or the equipment it protects, ensuring system integrity even in the most aggressive environments.

The Foundation: Unpacking Chemical Inertness

The exceptional performance of expanded PTFE (ePTFE) is not an additive feature; it is a direct result of the core chemistry of the material itself.

A Stable Molecular Structure

At its heart, PTFE is composed of a long chain of carbon atoms completely shielded by fluorine atoms. The bond between carbon and fluorine is one of the strongest in organic chemistry, making the molecule exceptionally stable and non-reactive.

This powerful molecular bond makes it energetically unfavorable for other chemicals to break it apart and cause degradation, which is the mechanism of chemical corrosion.

Purity is Key

Expanded PTFE is manufactured without additives, fillers, or binders. This means the resulting gasket possesses the pure, uncompromised chemical resistance of virgin PTFE.

Because there are no other materials present, there are no weak points for corrosive media to target. The gasket is uniformly resistant throughout its structure.

Resistance to Oxidation

Unlike most metals, PTFE does not react with oxygen or other oxidizing agents. It is fundamentally impervious to the process of oxidation, which is a common form of corrosion that causes rust and material decay in less robust materials.

How Inertness Translates to Sealing Performance

A gasket's ability to resist corrosion is only useful if it can also maintain a reliable seal. The properties of ePTFE ensure its chemical resilience directly contributes to its mechanical function.

An Impenetrable Physical Barrier

The ePTFE gasket acts as an inert shield between two flange faces. It physically separates corrosive process fluids from the underlying metal components of the equipment.

This prevents the acidic or alkaline media from ever making contact with the flanges, dramatically increasing the operational lifespan of the entire system.

Non-Wetting and Non-Contaminating

PTFE has an extremely low surface energy, which means liquids do not easily stick to it—a property known as being non-wetting.

Corrosive media beads up on the surface rather than being absorbed. This prevents the gasket from becoming a point of contamination and ensures it does not retain and concentrate chemicals that could cause issues later.

Maintaining Seal Integrity

Many materials swell, harden, or degrade when exposed to chemicals, causing them to lose their ability to seal. Because ePTFE is unaffected, it retains its softness, flexibility, and compressibility.

This ensures it continues to fill flange imperfections and maintain a tight, reliable seal over long periods, even under continuous exposure to harsh chemicals.

Understanding the Trade-offs

While its chemical resistance is nearly universal, ePTFE is not the solution for every single industrial application. Understanding its limitations is critical for proper selection.

Temperature Boundaries

The chemical stability of PTFE has limits. While it performs exceptionally well from cryogenic temperatures up to approximately +260°C (500°F), it will begin to degrade at extremely high temperatures.

Specific Chemical Exceptions

Although it is unaffected by the majority of chemicals, there are a few rare exceptions. Highly reactive substances like molten alkali metals and certain potent fluorinating agents can attack PTFE. Always verify compatibility in these extreme cases.

Mechanical Limitations

Expanded PTFE is a very soft material, which is excellent for sealing fragile or damaged flanges. However, it may not be suitable for extremely high-pressure applications where significant mechanical strength and rigidity are the primary requirements.

Making the Right Choice for Your Application

To determine if an expanded PTFE gasket is the correct choice, consider the primary demands of your sealing environment.

- If your primary focus is handling aggressive chemicals: ePTFE is a premier choice due to its near-universal chemical inertness against acids, bases, and solvents.

- If your primary focus is protecting fragile or uneven flanges: The high compressibility and softness of ePTFE make it ideal for creating a tight seal without risking damage to the equipment.

- If your primary focus is high-purity or non-contamination: The non-wetting and non-contaminating properties of ePTFE ensure it will not leach into or react with your process media.

Ultimately, leveraging ePTFE's properties provides an unparalleled defense against chemical attack, ensuring long-term reliability for critical sealing applications.

Summary Table:

| Key Property | Benefit for Corrosion Resistance |

|---|---|

| Pure PTFE Structure | No fillers or additives to create weak points for chemical attack |

| Strong Carbon-Fluorine Bonds | Exceptional molecular stability against reactive chemicals |

| Non-Wetting Surface | Prevents absorption and concentration of corrosive media |

| Temperature Range | Reliable performance from cryogenic to +260°C (+500°F) |

| Oxidation Resistance | Impervious to rust and oxygen-related degradation |

Protect your critical equipment with KINTEK's precision PTFE components

At KINTEK, we manufacture high-performance expanded PTFE gaskets and seals that deliver unmatched corrosion resistance for semiconductor, medical, laboratory, and industrial applications. Our pure PTFE components create impenetrable barriers against even the most aggressive chemicals, ensuring system integrity and preventing contamination.

Why choose KINTEK for your PTFE sealing solutions?

- Custom Fabrication: From prototypes to high-volume production runs

- Precision Engineering: Consistent quality and reliable performance

- Industry Expertise: Solutions tailored for your specific chemical environment

- Long-Term Reliability: Components that maintain seal integrity under continuous chemical exposure

Ready to solve your corrosion challenges? Contact our engineering team today to discuss your application requirements and get expert recommendations for optimal sealing performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the different grades of Teflon (PTFE) and their applications? A Guide to Material Selection

- What makes PTFE seals suitable for high-temperature applications? Unmatched Thermal & Chemical Stability

- What are some common industries and applications for PTFE/Teflon machined parts? Solve Harsh Environment Challenges

- Why can't PTFE be processed like other thermoplastics? Unlocking Its Unique Manufacturing Challenge

- What are some common fillers used in PTFE seal materials? Enhance Performance for Your Application

- What makes Teflon suitable for electrical applications? Unmatched Insulation for Extreme Conditions

- What makes PTFE liners suitable for high-temperature applications? Unlock Thermal Resilience for Demanding Processes

- What are the pros and cons of silicone sheets compared to Teflon sheets? Choose the Right Protective Sheet for Your Project