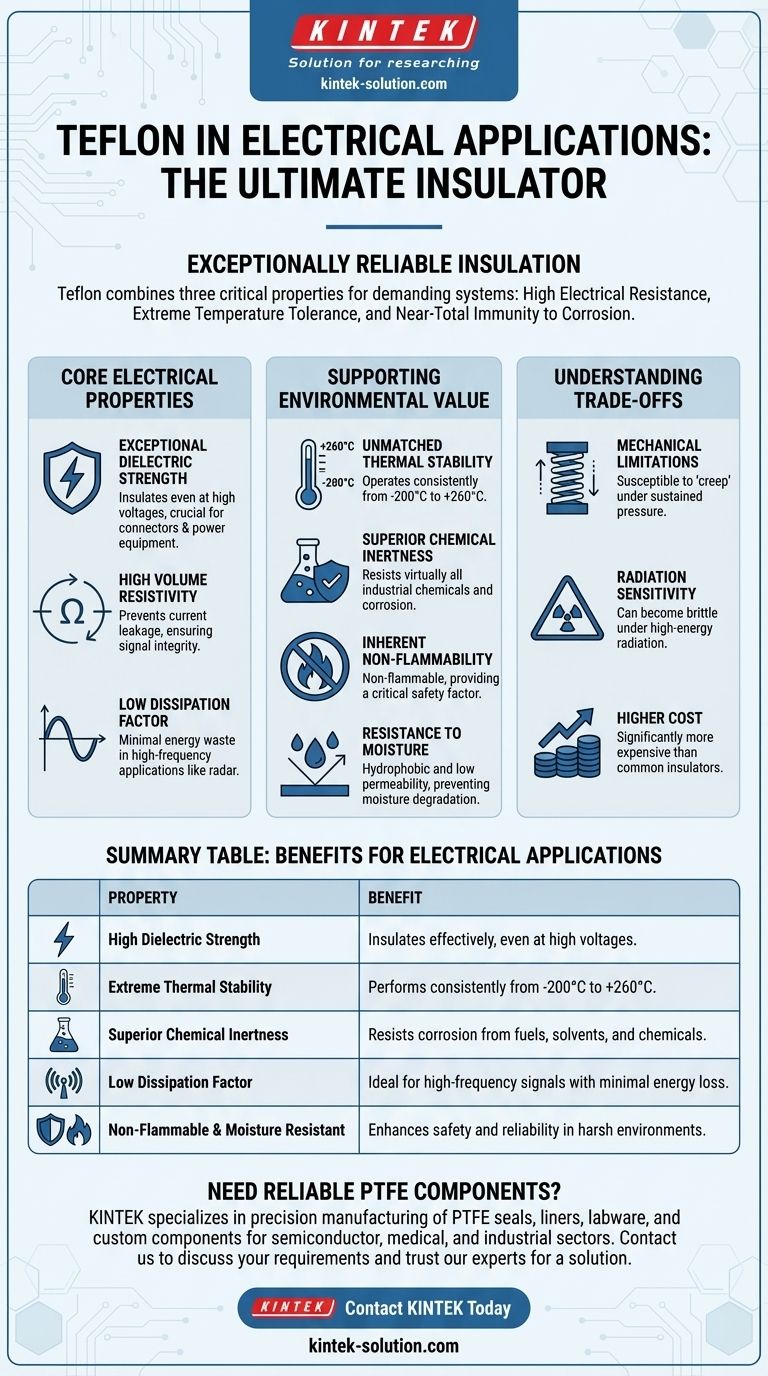

In short, Teflon is an exceptional material for electrical applications because it combines three critical properties: extremely high electrical resistance (dielectric strength), the ability to withstand a wide range of temperatures, and near-total immunity to chemical corrosion. This powerful combination ensures reliable and safe performance in demanding electrical and electronic systems where other materials would quickly fail.

The core reason for using Teflon isn't just its ability to insulate electricity; it's the material's remarkable consistency. It maintains its elite insulating properties under extreme heat, cold, and chemical exposure, making it a predictable and highly reliable choice for mission-critical applications.

The Core Electrical Properties of Teflon (PTFE)

While many materials can block electricity to some degree, Teflon (Polytetrafluoroethylene or PTFE) performs at an elite level. This performance is based on specific, measurable characteristics that make it a go-to insulator.

Exceptional Dielectric Strength

Dielectric strength measures a material's ability to withstand a strong electric field without breaking down and starting to conduct electricity.

Teflon possesses a very high dielectric strength, allowing it to insulate components even at high voltages. This makes it invaluable for high-voltage connectors, cable insulation, and components in power equipment.

High Volume Resistivity

This property defines how strongly a material resists the flow of electrical current through its bulk.

Teflon's high resistivity ensures that electricity stays contained within its intended conductor, preventing current leakage that can cause signal loss, short circuits, or energy waste.

Low Dissipation Factor

In high-frequency applications (like radio or radar), some insulating materials absorb and waste energy as heat.

Teflon has a very low dissipation factor, meaning it wastes minimal energy. This makes it a superior choice for high-frequency coaxial cables, connectors, and circuit boards where signal integrity is paramount.

Why Supporting Properties Magnify Its Electrical Value

Teflon’s electrical performance would be less meaningful if it couldn't survive its operating environment. Its unique physical and chemical properties ensure its electrical integrity is maintained under harsh conditions.

Unmatched Thermal Stability

Electrical components generate heat, and their environment can be extremely hot or cold.

Teflon operates consistently across a vast temperature range, from -200°C to +260°C (-328°F to +500°F). It will not melt, become brittle, or degrade, ensuring its insulating properties remain stable.

Superior Chemical Inertness

Many electrical systems operate in environments with fuels, solvents, or other corrosive chemicals.

Teflon is one of the most chemically inert substances known. It resists virtually all industrial chemicals, ensuring the insulation will not be compromised by corrosion or chemical attack.

Inherent Non-Flammability

The greatest risk in any electrical system is fire.

Teflon has an extremely high melting point and is non-flammable. This provides a critical safety factor, as it will not ignite or contribute to the spread of a fire caused by an electrical fault.

Resistance to Moisture

Water is conductive and a primary cause of electrical failure.

Teflon is hydrophobic (it repels water) and has extremely low permeability. It does not absorb moisture, which prevents the degradation of its insulating properties in humid or wet conditions.

Understanding the Trade-offs

No material is perfect for every situation. While Teflon's properties are exceptional, it's important to understand its limitations to make an informed decision.

Mechanical Limitations

Teflon is a relatively soft material. Under sustained pressure, it can be prone to "creep" or cold flow, meaning it can slowly deform over time. This makes it less suitable for high-load structural applications.

Radiation Sensitivity

Compared to some other polymers, Teflon does not stand up well to high-energy radiation (such as gamma rays). In these environments, its molecular structure can break down, causing it to become brittle.

Higher Cost

As a high-performance fluoropolymer, Teflon is significantly more expensive than common insulators like PVC or polyethylene. Its use is typically justified by the need for performance and reliability in demanding applications.

Making the Right Choice for Your Application

Selecting Teflon depends entirely on the performance and safety requirements of your project.

- If your primary focus is high-voltage or high-frequency insulation: Teflon is a superior choice due to its high dielectric strength and low energy loss, especially in aerospace and telecommunications.

- If your primary focus is reliability in extreme environments: Teflon's thermal stability and chemical inertness ensure it will not fail due to heat, chemical exposure, or moisture.

- If your primary focus is a standard, low-cost application: A more common insulator may be sufficient, provided the environment is benign and the performance demands are not severe.

By understanding this blend of electrical, thermal, and chemical properties, you can confidently specify Teflon for applications where failure is not an option.

Summary Table:

| Property | Benefit for Electrical Applications |

|---|---|

| High Dielectric Strength | Insulates effectively, even at high voltages. |

| Extreme Thermal Stability | Performs consistently from -200°C to +260°C. |

| Superior Chemical Inertness | Resists corrosion from fuels, solvents, and chemicals. |

| Low Dissipation Factor | Ideal for high-frequency signals with minimal energy loss. |

| Non-Flammable & Moisture Resistant | Enhances safety and reliability in harsh environments. |

Need reliable PTFE components for your demanding electrical application?

KINTEK specializes in the precision manufacturing of PTFE seals, liners, labware, and custom components. We understand that your projects in the semiconductor, medical, laboratory, and industrial sectors require materials that won't fail under extreme conditions. Our expertise ensures you get the electrical insulation, thermal stability, and chemical resistance you need, from prototypes to high-volume orders.

Contact KINTEK today to discuss your specific requirements and let our experts provide a solution you can trust.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability