When choosing between protective sheets, the decision between silicone and Teflon comes down to a fundamental trade-off. Teflon (PTFE) sheets offer superior non-stick properties and durability, making them ideal for release applications like heat pressing. Silicone sheets, while also heat-resistant, are valued for their flexibility and lower cost, serving best as a versatile, protective barrier.

The core difference is not which material is "better," but which is right for your specific task. Teflon excels at providing a flawless non-stick surface, while silicone excels at providing flexible, general-purpose heat protection.

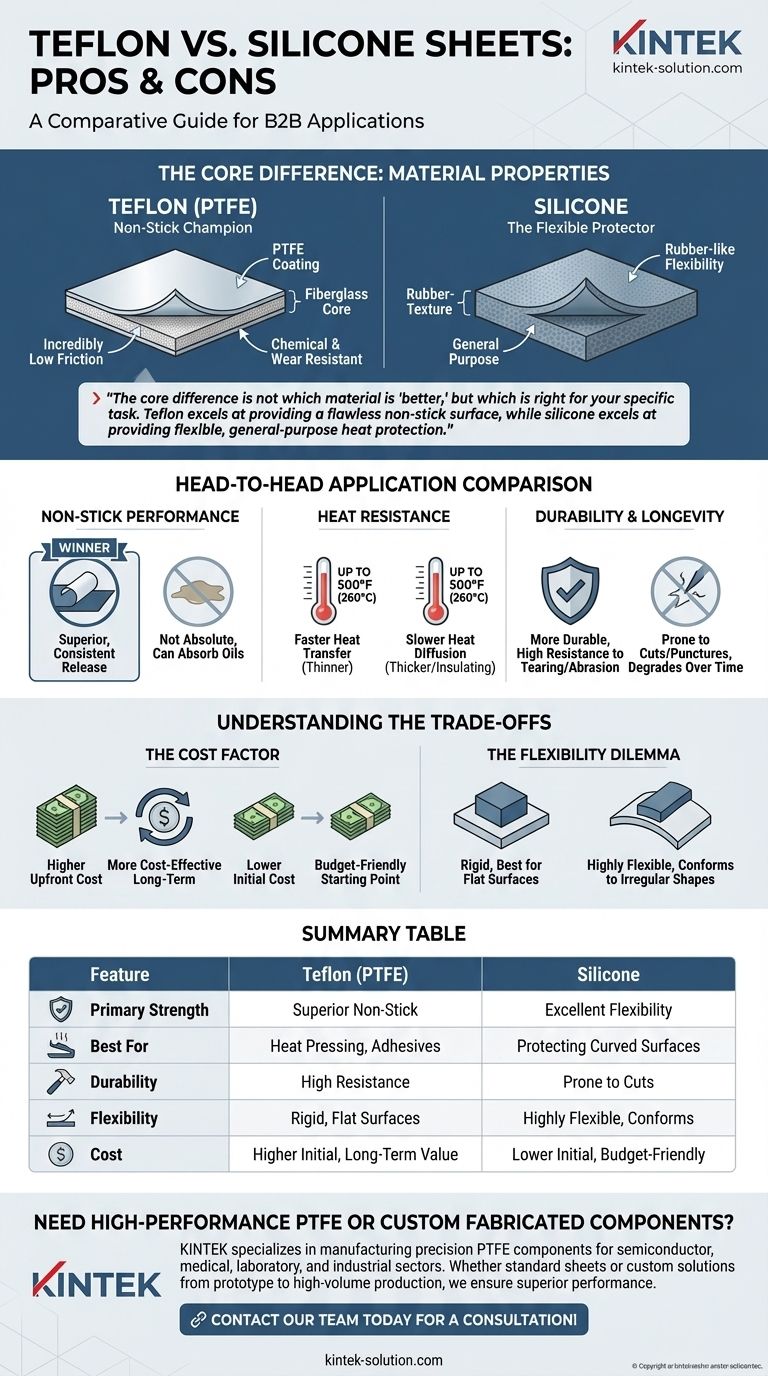

The Core Difference: Material Properties

To make an informed choice, you must first understand the materials themselves. Their inherent properties dictate their ideal uses.

Teflon (PTFE): The Non-Stick Champion

Teflon sheets are typically made of fiberglass cloth coated with Polytetrafluoroethylene (PTFE). This is the same material known for its use on non-stick cookware.

Its key characteristic is an incredibly low coefficient of friction. This chemical property is why almost nothing sticks to it, ensuring a clean release every time.

These sheets are generally thin, somewhat rigid, and highly resistant to chemical reactions and wear.

Silicone: The Flexible Protector

Silicone sheets are made from a synthetic polymer composed of silicon, oxygen, and other elements. This gives them a rubber-like texture.

Their main advantage is flexibility. A silicone sheet can be easily draped, wrapped, or fitted into irregular shapes.

While silicone is considered non-stick, its release properties are not as absolute as Teflon's. Over time, it can absorb oils or develop a tackiness that reduces its effectiveness.

Head-to-Head Application Comparison

How these properties translate to real-world use is what truly matters for your project.

For Non-Stick Performance

Teflon is the clear winner. If your primary goal is to prevent a material (like heat transfer vinyl, ink, or sticky food) from adhering to a surface, Teflon is the most reliable choice. Its release is consistent and clean.

For Heat Resistance

Both materials offer excellent heat resistance, generally up to 500°F (260°C) for Teflon and a similar or slightly lower range for most silicone sheets.

However, the thinner Teflon sheet allows for more direct and rapid heat transfer. The thicker, more insulating nature of silicone can sometimes diffuse heat more slowly, which may or may not be desirable depending on the application.

For Durability and Longevity

Teflon is more durable for most applications. The PTFE-coated fiberglass construction is highly resistant to tearing, abrasion, and repeated use.

Silicone is softer and more prone to being cut, punctured, or degrading over time, especially if it comes into contact with sharp objects or aggressive cleaning.

Understanding the Trade-offs

Neither material is perfect for every scenario. Acknowledging their limitations is key to avoiding frustration.

The Cost Factor

Silicone sheets typically have a lower initial cost, making them an accessible option for general use or for projects where the sheet may be damaged.

Teflon sheets have a higher upfront price. However, their superior durability and reusability can make them more cost-effective in the long run for high-volume or demanding tasks.

The Flexibility Dilemma

Silicone's flexibility is its greatest strength. It’s perfect for protecting a curved work surface or lining a non-standard baking pan.

Teflon's relative rigidity makes it unsuitable for these tasks. It excels on flat surfaces, such as the platen of a heat press or a flat baking sheet.

The Limits of "Non-Stick"

The "not always non-stick" nature of silicone is a critical consideration. While it performs well initially, some materials can begin to adhere to it after repeated use. Teflon's non-stick quality is inherent to its chemistry and far more permanent.

Making the Right Choice for Your Task

Your specific goal should dictate your choice. Use this guide to select the appropriate material.

- If your primary focus is flawless non-stick release (e.g., heat pressing vinyl, working with adhesives): Choose Teflon for its unmatched and durable release properties.

- If your primary focus is flexibility and general heat protection (e.g., protecting a work surface, lining an irregular pan): Choose Silicone for its pliability and lower cost.

- If your primary focus is long-term durability and reusability for flat applications: Choose Teflon for its superior resistance to wear and tear.

- If your primary focus is the lowest initial cost for general-purpose use: Choose Silicone as the more budget-friendly starting point.

Understanding these material differences empowers you to select the precise tool for your specific application.

Summary Table:

| Feature | Teflon (PTFE) Sheets | Silicone Sheets |

|---|---|---|

| Primary Strength | Superior, permanent non-stick release | Excellent flexibility and pliability |

| Best For | Heat pressing, adhesives, flawless release | Protecting curved surfaces, general-purpose use |

| Durability | High resistance to wear, tear, and abrasion | Softer, more prone to cuts and punctures |

| Flexibility | Rigid, best for flat surfaces | Highly flexible, conforms to irregular shapes |

| Cost | Higher initial cost, more cost-effective long-term | Lower initial cost, budget-friendly |

Need High-Performance PTFE or Custom Fabricated Components?

This comparison highlights the unique strengths of Teflon (PTFE). At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

Whether you require standard sheets or a custom-fabricated solution from prototype to high-volume production, our expertise ensures superior non-stick performance, chemical resistance, and durability.

Let us provide the right material solution for your specific needs. Contact our team today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability