Machined PTFE/Teflon parts are indispensable in demanding sectors like aerospace, medical, chemical processing, and electronics. Their most common applications are for components that require extreme chemical resistance, low friction, or high-temperature stability, including seals, gaskets, bearings, and electrical insulators.

The core reason for PTFE's widespread use is not a single feature, but its unique combination of properties. It solves engineering challenges in harsh environments where temperature, chemical exposure, or friction would cause most other materials to fail.

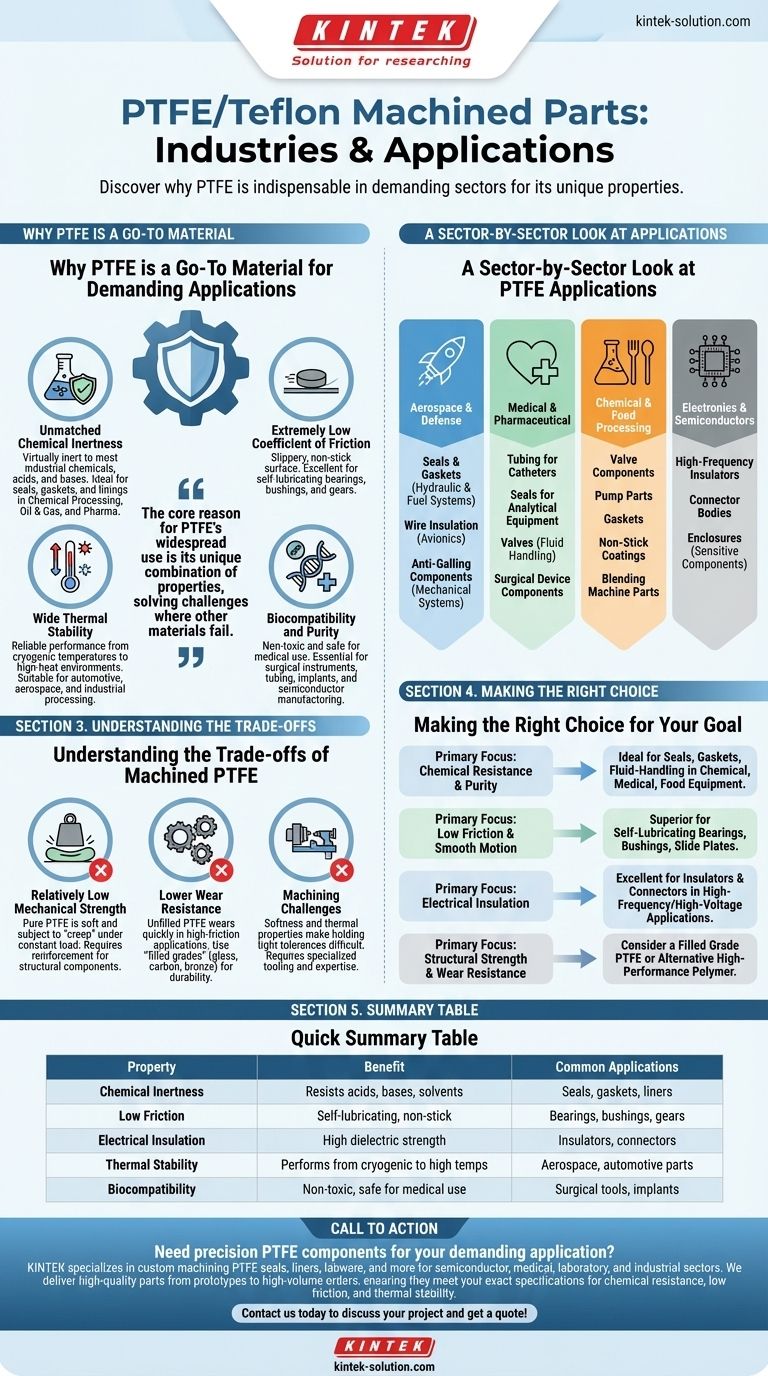

Why PTFE is a Go-To Material for Demanding Applications

The value of machined PTFE parts is rooted in a set of distinct material properties. Understanding these characteristics explains why it is specified for such critical roles across various industries.

Unmatched Chemical Inertness

PTFE is virtually inert and does not react with almost any industrial chemical, acid, or base. This makes it the default choice for seals, gaskets, and linings in the chemical processing, oil and gas, and pharmaceutical industries.

Extremely Low Coefficient of Friction

Known for its slippery, non-stick surface, PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating property is ideal for creating high-performance, maintenance-free bearings, bushings, and gears in mechanical systems.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with a high dielectric strength, meaning it can withstand high voltages without breaking down. This quality is critical for components like insulators, connectors, and cable insulation in the electronics and aerospace industries.

Wide Thermal Stability

The material performs reliably across an exceptionally broad temperature range. This stability makes it suitable for components in high-temperature automotive engines, cryogenic aerospace systems, and industrial processing equipment.

Biocompatibility and Purity

PTFE is non-toxic and biocompatible, meaning it can be safely used in direct contact with living tissue. This is essential for applications in the medical field, such as surgical instruments, tubing, and even some implants. Its purity is also vital in semiconductor manufacturing.

A Sector-by-Sector Look at PTFE Applications

Different industries leverage specific PTFE properties to solve their unique engineering problems.

In Aerospace and Defense

This sector relies on PTFE for its reliability in extreme conditions. Key parts include seals and gaskets for hydraulic and fuel systems, wire insulation for complex avionics, and anti-galling components in mechanical systems.

In Medical and Pharmaceutical

Biocompatibility and chemical resistance are paramount here. PTFE is machined into tubing for catheters, seals for analytical equipment, valves for fluid handling, and components for surgical devices.

In Chemical and Food Processing

The combination of chemical inertness and non-stick properties is a perfect match for this sector. Applications include valve components, pump parts, gaskets, non-stick coatings, and parts for blending machines that require easy cleaning.

In Electronics and Semiconductors

The need for electrical insulation and material purity drives PTFE's use in this industry. It is commonly machined into high-frequency insulators, connector bodies, and enclosures for sensitive electronic components.

Understanding the Trade-offs of Machined PTFE

While PTFE is a powerful problem-solver, it is not a universal solution. An objective assessment requires acknowledging its limitations.

Relatively Low Mechanical Strength

Pure PTFE is a soft material and can deform under a constant load, a phenomenon known as "creep." It is not suitable for high-load structural components without reinforcement.

Lower Wear Resistance

In high-friction applications, unfilled PTFE can wear more quickly than other polymers. To counteract this, fillers like glass, carbon, or bronze are often added to create "filled grades" with significantly improved durability.

Machining Challenges

Its softness and thermal properties can make holding extremely tight tolerances a challenge. Machining PTFE effectively requires specialized tooling, techniques, and experience to prevent deformation and ensure precision.

Making the Right Choice for Your Goal

Selecting the right material depends entirely on the primary demand of your application.

- If your primary focus is chemical resistance and purity: PTFE is an ideal choice for seals, gaskets, and fluid-handling components in chemical, medical, or food-grade equipment.

- If your primary focus is low friction and smooth motion: It is a superior material for self-lubricating bearings, bushings, and slide plates in mechanical assemblies.

- If your primary focus is electrical insulation: It is an excellent option for insulators and connectors, especially in high-frequency or high-voltage applications.

- If your primary focus is structural strength and wear resistance: You should strongly consider a filled grade of PTFE or an alternative high-performance polymer designed for mechanical stress.

Understanding PTFE's core strengths and limitations empowers you to leverage it precisely where its unique capabilities will deliver the most value.

Summary Table:

| Property | Benefit | Common Applications |

|---|---|---|

| Chemical Inertness | Resists acids, bases, and solvents | Seals, gaskets, liners |

| Low Friction | Self-lubricating, non-stick | Bearings, bushings, gears |

| Electrical Insulation | High dielectric strength | Insulators, connectors |

| Thermal Stability | Performs from cryogenic to high temps | Aerospace, automotive parts |

| Biocompatibility | Non-toxic, safe for medical use | Surgical tools, implants |

Need precision PTFE components for your demanding application? KINTEK specializes in custom machining PTFE seals, liners, labware, and more for the semiconductor, medical, laboratory, and industrial sectors. We deliver high-quality parts from prototypes to high-volume orders, ensuring they meet your exact specifications for chemical resistance, low friction, and thermal stability. Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments