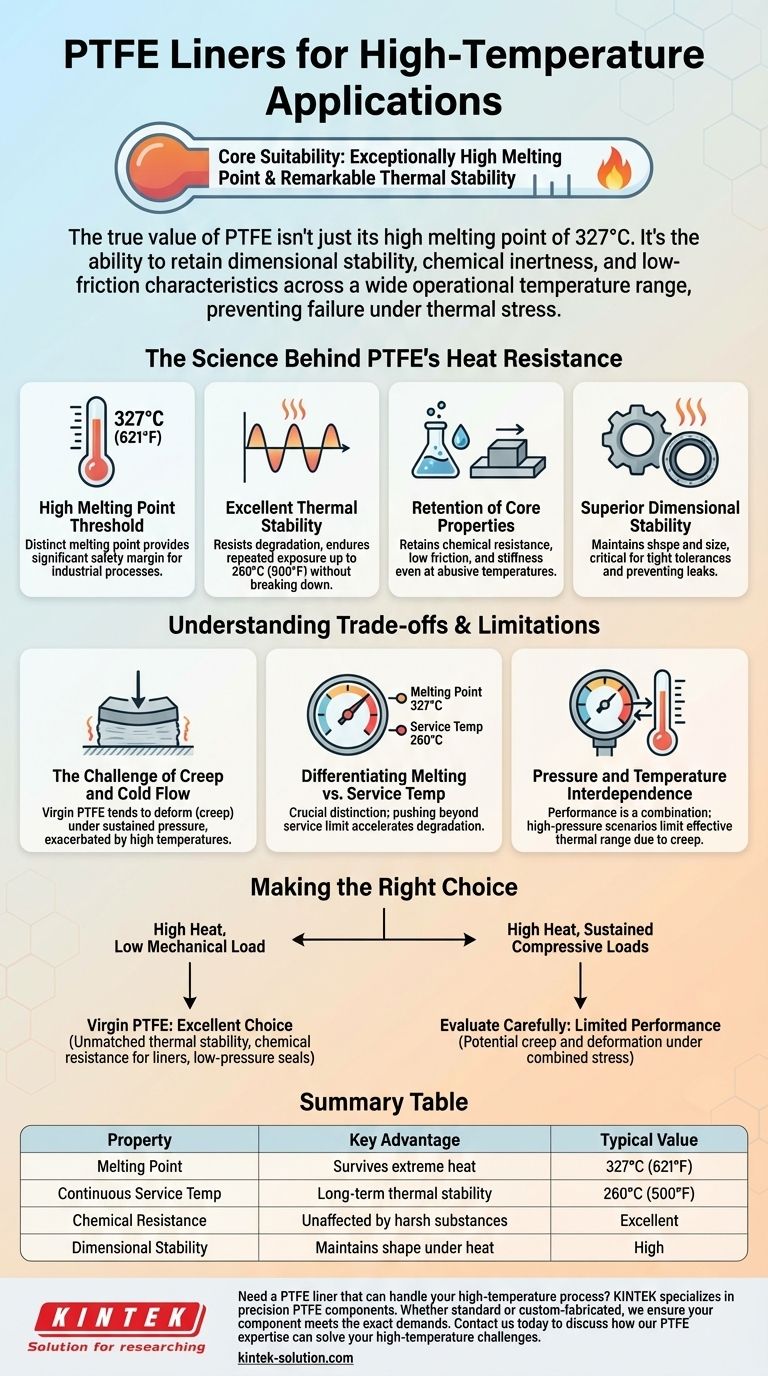

At its core, PTFE's suitability for high-temperature applications stems from its exceptionally high melting point and remarkable thermal stability. This unique combination allows it to not only survive extreme heat but also to maintain its essential physical and chemical properties, ensuring reliable performance where other materials would degrade or fail.

The true value of PTFE isn't just its high melting point of 327°C. It's the material's ability to retain its dimensional stability, chemical inertness, and low-friction characteristics across a wide operational temperature range, preventing failure under thermal stress.

The Science Behind PTFE's Heat Resistance

To understand why PTFE liners and components are specified for demanding thermal environments, we must look beyond a single temperature rating and analyze how the material behaves under heat.

The High Melting Point Threshold

PTFE has a distinct melting point of approximately 327°C (621°F). This high threshold provides a significant safety margin for a vast number of industrial processes, making it a reliable replacement for weaker plastics that cannot withstand such temperatures.

Excellent Thermal Stability

Beyond simply not melting, PTFE resists thermal degradation. It can endure repeated exposure to high temperatures up to its continuous service limit of 260°C (500°F) without breaking down or becoming brittle, ensuring longevity in applications with frequent thermal cycling.

Retention of Core Properties

A material's ability to simply survive heat is useless if it cannot perform its function. PTFE excels because it retains its most valued characteristics—like chemical resistance, low friction, and stiffness—even at abusive temperatures. This ensures consistent, predictable performance.

Superior Dimensional Stability

Unlike many metals that can deform or fail due to thermal expansion, PTFE components like bushes and seals maintain their shape and size. This dimensional stability is critical for maintaining tight tolerances and preventing leaks in high-temperature systems.

Understanding the Trade-offs and Limitations

No material is perfect, and objectivity requires acknowledging PTFE's operational boundaries. Its exceptional heat resistance comes with specific mechanical limitations that are critical to consider during design and material selection.

The Challenge of Creep and Cold Flow

The most significant limitation of virgin PTFE is its tendency to "creep" or deform over time when subjected to sustained pressure. This cold flow phenomenon can be exacerbated at higher temperatures, potentially leading to a loss of surface pressure and seal integrity.

Differentiating Melting vs. Service Temperature

It is crucial to distinguish between the melting point (327°C) and the maximum continuous service temperature (around 260°C). Pushing PTFE beyond its service temperature, even if below its melting point, can accelerate degradation and compromise its mechanical properties.

Pressure and Temperature Interdependence

The performance of PTFE is not just about temperature; it's about the combination of temperature and pressure. An application with mild pressure may allow for use at higher temperatures, whereas high-pressure scenarios may limit the effective thermal range due to the risk of creep.

Making the Right Choice for Your Application

Selecting the right material requires aligning its properties with the specific demands of your project. Use these guidelines to determine if PTFE is the optimal choice.

- If your primary focus is high heat without significant mechanical load: Virgin PTFE is an excellent choice, offering unmatched thermal stability and chemical resistance for liners, containers, and low-pressure seals.

- If your application involves both high heat and sustained compressive loads: You must carefully evaluate virgin PTFE for potential creep and deformation, as its performance is limited under these combined stresses.

Understanding both PTFE's thermal resilience and its mechanical limits is the key to successfully deploying it in demanding environments.

Summary Table:

| Property | Key Advantage | Typical Value |

|---|---|---|

| Melting Point | Survives extreme heat | 327°C (621°F) |

| Continuous Service Temp | Long-term thermal stability | 260°C (500°F) |

| Chemical Resistance | Unaffected by harsh substances | Excellent |

| Dimensional Stability | Maintains shape under heat | High |

Need a PTFE liner that can handle your high-temperature process?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical balance between thermal resilience and mechanical performance.

Whether you require a standard solution or a custom-fabricated part from prototype to high-volume production, we ensure your component meets the exact demands of your application.

Contact us today to discuss how our PTFE expertise can solve your high-temperature challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection