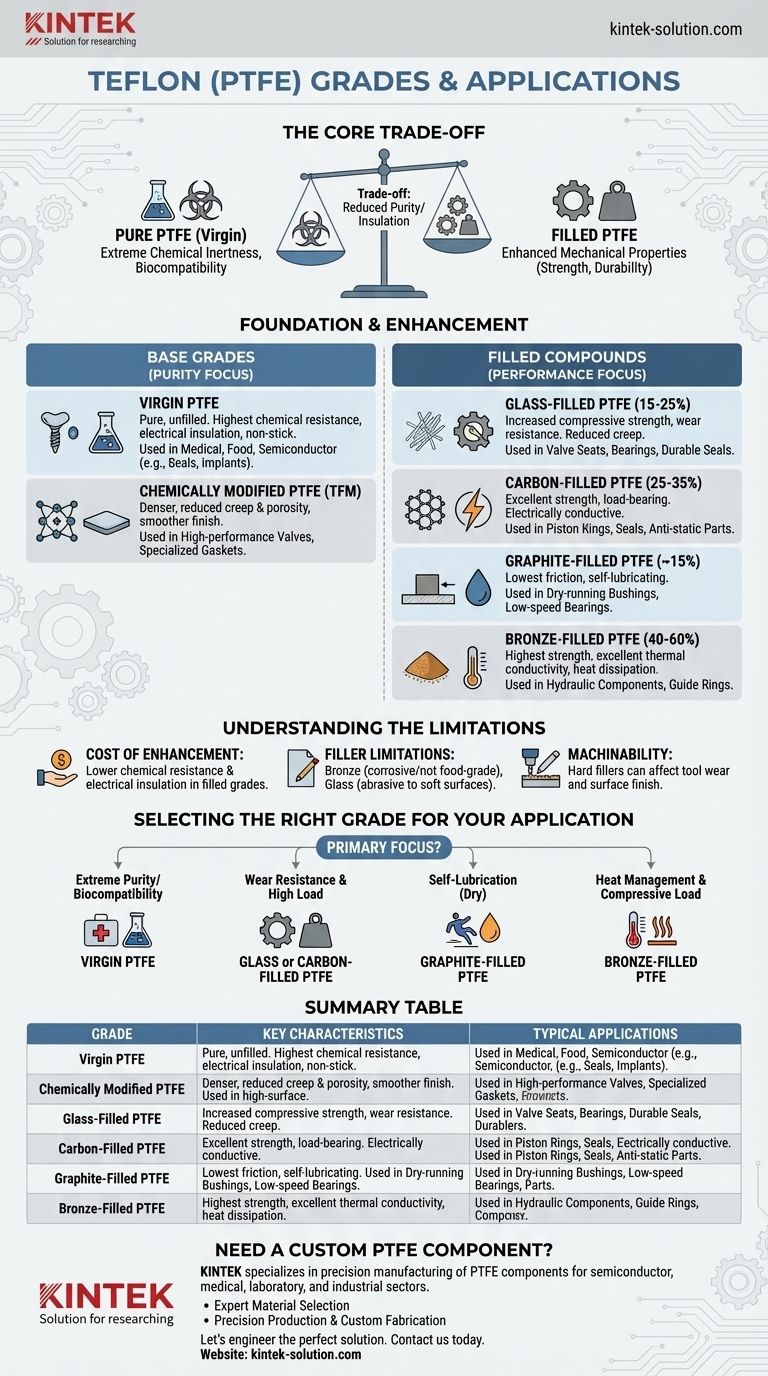

The primary grades of Teflon (PTFE) are categorized into three families: Virgin PTFE, Chemically Modified PTFE, and a wide range of Filled PTFE Compounds. Virgin PTFE is pure Polytetrafluoroethylene, prized for its extreme chemical inertness and biocompatibility. Filled grades enhance this base material by adding agents like glass, carbon, or bronze to improve specific mechanical properties such as wear resistance, compressive strength, or thermal conductivity.

The core decision in selecting a PTFE grade is understanding the trade-off. While pure PTFE offers unmatched chemical resistance and low friction, its mechanical properties are often insufficient for demanding applications. Adding fillers dramatically improves strength and durability at the cost of slightly reduced chemical inertness and electrical insulation.

The Foundation: Understanding Base PTFE Grades

The journey into material selection begins with the purest forms of PTFE. These grades set the baseline for performance and are the ideal choice when chemical purity is the absolute priority.

Virgin PTFE

Virgin PTFE is the pure, unfilled grade of Polytetrafluoroethylene. It contains no recycled material or additives.

This grade offers the highest physical and electrical insulation properties and the most extreme chemical resistance. Its inherent lubricity and non-stick surface are legendary.

It is the standard for applications in the medical, food processing, and semiconductor industries, where purity, non-reactivity, and biocompatibility are non-negotiable. Common uses include seals, gaskets, valves, and medical implants.

Chemically Modified PTFE

This is a slightly altered version of virgin PTFE, often referred to as TFM. A co-monomer is added during polymerization.

This modification results in a denser polymer structure, which significantly reduces creep (deformation under load) and porosity. It also provides a smoother surface finish after machining.

Chemically modified PTFE is used in demanding sealing applications where lower deformation and permeability are critical, such as in high-performance valve seats and specialized gaskets.

Enhancing Performance: Filled PTFE Compounds

When mechanical performance is a key driver, fillers are added to base PTFE. Each filler is chosen to impart a specific, desirable characteristic to the final material.

Glass-Filled PTFE

This is one of the most common filled grades, typically containing 15% to 25% glass fibers.

Adding glass significantly increases compressive strength and wear resistance compared to virgin PTFE. It dramatically reduces creep and is chemically stable in most environments.

Glass-filled PTFE is frequently used for valve seats, bearings, and seals that operate under high loads and require long-term durability.

Carbon-Filled PTFE

Carbon, typically in powder or fiber form, is added in concentrations of 25% to 35%.

This compound provides excellent compressive strength and load-bearing capabilities, even better than glass-filled grades. It is also electrically conductive, which can be useful for anti-static applications.

Its high mechanical strength makes it ideal for dynamic applications like piston rings, seals, and bearings that handle significant pressure.

Graphite-Filled PTFE

A small amount of graphite, usually around 15%, is added to the PTFE base.

Graphite is an excellent dry lubricant. This grade offers some of the lowest coefficients of friction among all filled PTFE variants, making it highly self-lubricating.

It is primarily used for bushings and bearings in dry-running or low-speed applications where external lubrication is not possible.

Bronze-Filled PTFE

This grade contains a high percentage of bronze powder, ranging from 40% to 60%.

The metallic filler gives the material the highest compressive strength and wear resistance of all PTFE compounds. Crucially, it also provides excellent thermal conductivity, allowing it to dissipate heat away from the operating surface.

It is the material of choice for high-load, high-speed applications like hydraulic system components and guide rings where heat generation is a concern.

Understanding the Trade-offs

Selecting an enhanced, filled grade of PTFE is not without its compromises. Understanding these limitations is critical for successful application.

The Cost of Enhancement

Adding any filler material will slightly diminish some of PTFE's signature properties. Chemical resistance and electrical insulation are typically lower in filled grades compared to virgin PTFE.

Filler Material Matters

The filler itself introduces limitations. Bronze-filled PTFE, for example, has poor resistance to corrosive chemicals and is not suitable for food-grade or electrical applications. Glass-filled grades can be abrasive to softer mating surfaces like stainless steel over time.

Machinability and Finish

While all PTFE grades are readily machinable, achieving a very fine surface finish can be more challenging with filled compounds. The presence of hard filler particles can affect tool wear and the final texture of the part.

Selecting the Right PTFE Grade for Your Application

Your final decision should be driven by the single most critical performance requirement of your component.

- If your primary focus is extreme chemical purity or biocompatibility: Virgin PTFE is the only reliable choice for medical, semiconductor, or pure fluid handling.

- If your primary focus is wear resistance under high mechanical load: Glass-filled or carbon-filled PTFE provide the necessary strength and durability.

- If your primary focus is self-lubrication in dry-running conditions: Graphite-filled PTFE offers the best performance for low-friction, unlubricated sliding parts.

- If your primary focus is managing heat and high compressive loads: Bronze-filled PTFE excels at thermal dissipation in demanding hydraulic and bearing applications.

Choosing the correct material is a matter of deliberately matching the unique properties of each PTFE grade to the specific demands of your engineering challenge.

Summary Table:

| Grade | Key Characteristics | Typical Applications |

|---|---|---|

| Virgin PTFE | Highest chemical resistance, biocompatibility, low friction | Medical implants, semiconductor seals, food processing liners |

| Chemically Modified PTFE | Reduced creep, lower porosity, smoother finish | High-performance valve seats, specialized gaskets |

| Glass-Filled PTFE | High wear resistance, good compressive strength | Valve seats, bearings, durable seals |

| Carbon-Filled PTFE | Excellent compressive strength, electrically conductive | Piston rings, high-load bearings, anti-static parts |

| Graphite-Filled PTFE | Very low friction, excellent self-lubrication | Dry-running bushings, low-speed bearings |

| Bronze-Filled PTFE | Highest compressive strength, excellent thermal conductivity | High-load hydraulic components, guide rings |

Need a Custom PTFE Component for Your Application?

Choosing the right PTFE grade is critical for performance and longevity. KINTEK specializes in the precision manufacturing of PTFE components—from seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors.

We provide:

- Expert Material Selection: We'll help you navigate the trade-offs to select the optimal PTFE grade for your specific needs, whether it's chemical purity, wear resistance, or thermal management.

- Precision Production & Custom Fabrication: From initial prototypes to high-volume orders, our manufacturing prioritizes precision and quality to meet your exact specifications.

Let's engineer the perfect solution for your challenge. Contact our team today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the benefits of using custom Teflon parts for clients? Reduce Costs & Boost Reliability

- What are the physical properties of PTFE balls? A Guide to Extreme Chemical & Thermal Performance

- What are the operating temperature ranges for PTFE and nylon? Choose the Right Polymer for Extreme or Moderate Heat

- How is a PTFE bearing pad installed on cast-in-place beams? Master the Critical Pre-Pour Integration

- What is the primary advantage of PTFE control valves? Unmatched Chemical Resistance for Harsh Fluids

- What are the operational benefits of PTFE Lip Seals? Unlock Reliability in Extreme Conditions

- What are the key advantages of PTFE-jacketed spring energized seals? Unlock Unmatched Sealing Performance

- What are the key characteristics of PTFE oil seals? Unlock Superior Performance in Extreme Conditions