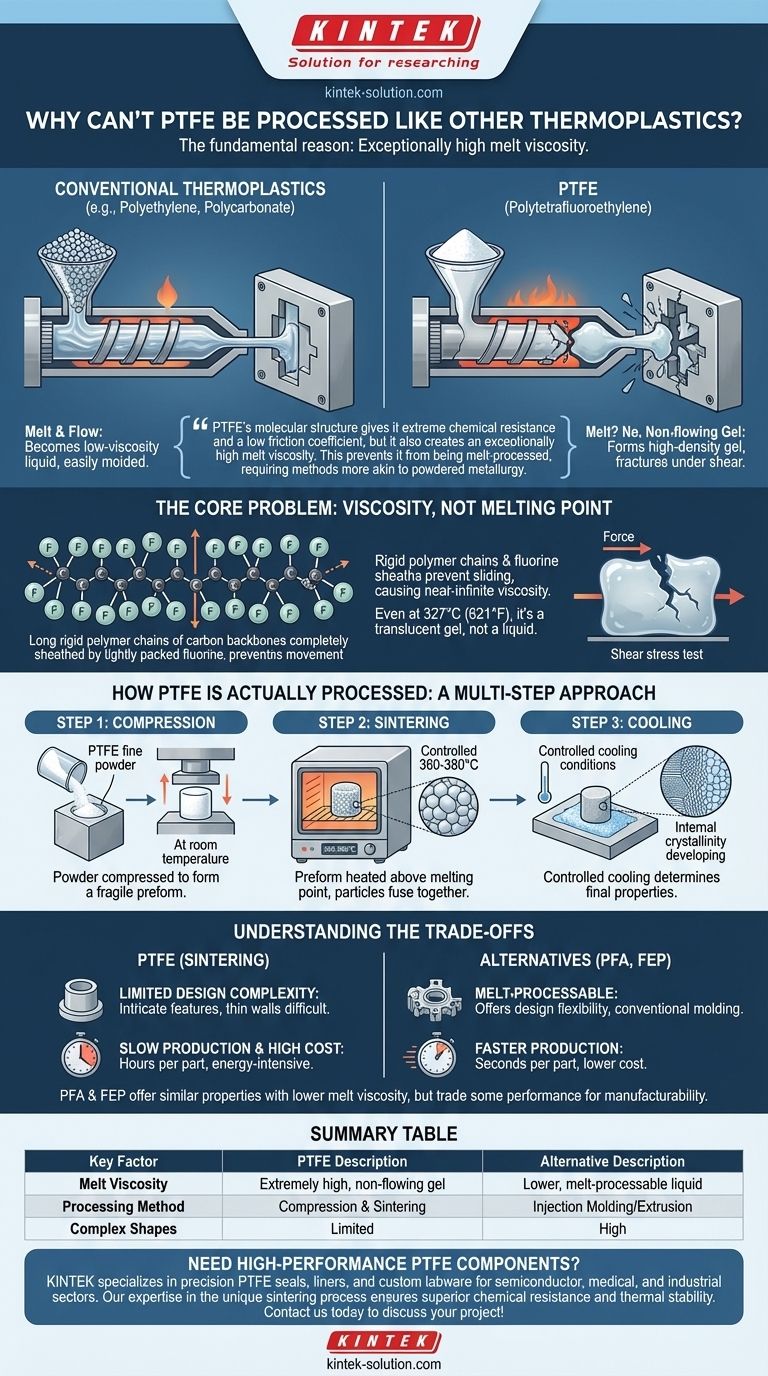

The fundamental reason PTFE cannot be processed like other thermoplastics is its exceptionally high melt viscosity. Even when heated well above its melting point, it does not flow like a liquid. Instead, it forms a soft, non-flowing gel that fractures under the shear stress of conventional injection molding or extrusion.

PTFE's molecular structure gives it extreme chemical resistance and a low friction coefficient, but it also creates an exceptionally high melt viscosity. This prevents it from being melt-processed, requiring methods more akin to powdered metallurgy than traditional plastics processing.

The Core Problem: Viscosity, Not Melting Point

A Misleading "Melt" Point

PTFE does have a true melting point at approximately 327°C (621°F). However, this transition is deceptive.

Unlike polymers like polyethylene or polycarbonate which become low-viscosity liquids, PTFE transitions into a translucent, high-density gel. This gel has virtually no flow characteristics.

The Molecular Reason for High Viscosity

The source of this behavior is PTFE's molecular structure. It consists of very long, rigid polymer chains of a carbon backbone completely sheathed by fluorine atoms.

These strong, tightly packed fluorine sheaths prevent the polymer chains from easily sliding past one another, even when thermal energy is applied. The material softens, but the chains remain entangled, resulting in near-infinite viscosity.

The Challenge of Shear Stress

Injection molding and extrusion rely on forcing molten plastic through small gates and nozzles at high pressure. This process creates immense shear stress.

When this force is applied to the PTFE gel, the entangled molecular chains don't untangle and flow. Instead, the material tears and fractures, resulting in a useless, defective part.

How PTFE is Actually Processed

Because melt processing is impossible, PTFE requires a completely different, multi-step approach that avoids forcing the material to flow.

Step 1: Compression

The process begins with PTFE resin in the form of a fine powder. This powder is poured into a mold and compressed under high pressure at room temperature to create a solid, but still fragile, object known as a "preform."

Step 2: Sintering

The preform is carefully removed from the mold and heated in a controlled oven above its melting point (typically between 360-380°C).

During this sintering phase, the individual powder particles fuse together, creating a solid, dense, and homogenous mass. The overall shape does not flow or change.

Step 3: Cooling

Finally, the sintered part is cooled under carefully controlled conditions. The rate of cooling is critical as it influences the material's crystallinity, which in turn affects its final physical properties like hardness, flexibility, and dimensional stability.

Understanding the Trade-offs

Design and Complexity Limitations

This compression and sintering process severely limits the geometric complexity of PTFE parts. Intricate features, sharp internal corners, and very thin walls are difficult or impossible to achieve, unlike with injection molding.

Production Speed and Cost

Sintering is a slow, energy-intensive batch process. The cycle times for creating a single part can be hours, compared to seconds for injection molding. This makes PTFE parts significantly more expensive to produce.

The Rise of Alternatives

To address these limitations, chemists developed melt-processable fluoropolymers like PFA (Perfluoroalkoxy) and FEP (Fluorinated Ethylene Propylene). These materials offer properties very similar to PTFE but have a lower melt viscosity, allowing them to be processed using conventional injection molding and extrusion.

Making the Right Choice for Your Application

Choosing the correct fluoropolymer requires balancing performance needs with manufacturing constraints.

- If your primary focus is maximum temperature stability and chemical inertness: Virgin PTFE processed via sintering remains the superior choice, but you must design the part with the manufacturing method's limitations in mind.

- If your primary focus is producing complex shapes at higher volumes: You should investigate melt-processable alternatives like PFA or FEP, which trade a small amount of performance for vastly superior manufacturability.

Understanding that PTFE is processed more like a ceramic than a typical plastic is the key to leveraging its unique properties effectively.

Summary Table:

| Key Factor | Description |

|---|---|

| Melt Viscosity | Extremely high; forms a non-flowing gel even above melting point |

| Molecular Structure | Rigid chains with fluorine sheaths prevent chain sliding |

| Shear Stress Response | Fractures under pressure instead of flowing |

| Processing Method | Compression molding followed by sintering (not injection molding) |

| Alternative Materials | PFA and FEP offer similar properties with melt-processability |

Need high-performance PTFE components? KINTEK specializes in manufacturing precision PTFE seals, liners, and custom labware for the semiconductor, medical, and industrial sectors. Our expertise in the unique sintering process required for PTFE ensures you get parts with superior chemical resistance and thermal stability. Whether you need prototypes or high-volume production, we deliver solutions tailored to your exact specifications. Contact us today to discuss your project and benefit from our specialized fabrication capabilities!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications