At its core, the suitability of Polytetrafluoroethylene (PTFE) for high-temperature applications stems from its incredibly stable molecular structure. This stability gives it a very high melting point and allows it to retain its essential mechanical and chemical properties even when exposed to extreme heat.

The fundamental reason PTFE seals excel in high-temperature environments is not just their resistance to melting, but their ability to maintain dimensional stability, strength, and chemical inertness without degrading, ensuring reliable performance where other materials would fail.

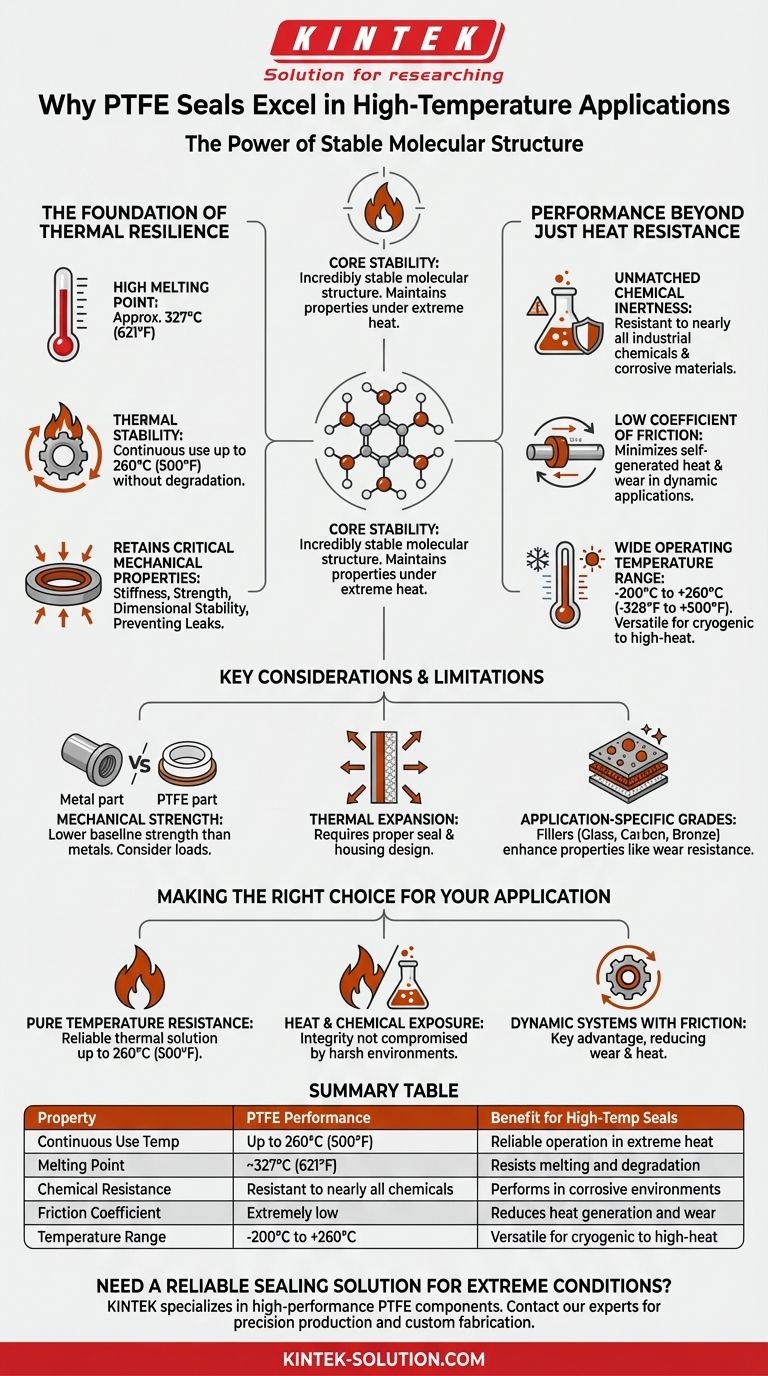

The Foundation of PTFE's Thermal Resilience

Understanding why PTFE works requires looking at how it behaves under thermal stress. Its performance is not based on a single attribute but on a combination of inherent properties that work together.

High Melting Point and Thermal Stability

The most immediate factor is PTFE's high melting point, which is approximately 327°C (621°F). This is significantly higher than many other plastics.

Crucially, PTFE possesses excellent thermal stability. This means it can endure repeated exposure to high operational temperatures—up to 260°C (500°F)—without breaking down or losing its integrity.

Retention of Critical Mechanical Properties

A seal is useless if it becomes brittle or deforms under heat. PTFE excels because it retains its key mechanical properties at elevated temperatures.

These properties include stiffness, strength, and dimensional stability. This ensures the seal maintains its shape and continues to provide an effective barrier, preventing leaks even in demanding conditions.

Performance Beyond Just Heat Resistance

While temperature tolerance is the primary reason for its selection, other characteristics make PTFE a uniquely effective sealing material in harsh environments.

Unmatched Chemical Inertness

High-temperature applications often involve aggressive chemicals, fuels, or solvents. PTFE is chemically resistant to nearly all industrial chemicals, ensuring it will not degrade when exposed to corrosive materials.

Low Coefficient of Friction

For dynamic applications like rotating shafts, friction is a major source of heat and wear. PTFE has an extremely low coefficient of friction, which minimizes self-generated heat and allows for smooth, efficient operation.

Wide Operating Temperature Range

PTFE's versatility extends to cold environments as well. It maintains its properties across a vast temperature spectrum, typically from -200°C to +260°C (-328°F to +500°F), making it suitable for both cryogenic and high-heat applications.

Key Considerations and Limitations

While PTFE is an exceptional material, its effective use requires understanding its context and limitations. An expert advisor must account for the entire system, not just one component.

Mechanical Strength vs. Metals

Although PTFE retains its strength at high temperatures, its baseline strength and rigidity are lower than metals. In applications where a component might face significant mechanical load, a metal bush might be more appropriate, though it could fail from thermal expansion where PTFE would not.

Thermal Expansion

Like all materials, PTFE expands with heat. Proper seal and housing design must account for this thermal expansion to ensure a consistent sealing force is maintained across the entire operating temperature range.

The Importance of Application-Specific Grades

Standard PTFE is not always the final answer. To enhance properties like wear resistance or reduce creep under load, fillers such as glass, carbon, or bronze are often added to create composite PTFE materials tailored for specific, highly demanding applications.

Making the Right Choice for Your Application

Selecting the right seal material is critical for system reliability. Your decision should be guided by the most demanding aspect of your operating environment.

- If your primary focus is pure temperature resistance: PTFE's high melting point and ability to operate continuously up to 260°C (500°F) provide a reliable thermal solution.

- If your application involves both heat and chemical exposure: PTFE's combination of thermal stability and near-total chemical inertness ensures the seal's integrity will not be compromised.

- If you are designing a dynamic system with friction concerns: PTFE's low friction coefficient is a key advantage, reducing wear and heat generation in rotating or moving parts.

Ultimately, PTFE's unique molecular structure provides a powerful combination of thermal, chemical, and mechanical stability that makes it an indispensable material for reliable sealing in extreme environments.

Summary Table:

| Property | PTFE Performance | Benefit for High-Temp Seals |

|---|---|---|

| Continuous Use Temperature | Up to 260°C (500°F) | Reliable operation in extreme heat |

| Melting Point | ~327°C (621°F) | Resists melting and degradation |

| Chemical Resistance | Resistant to nearly all industrial chemicals | Performs in corrosive environments |

| Friction Coefficient | Extremely low | Reduces heat generation and wear in dynamic seals |

| Temperature Range | -200°C to +260°C (-328°F to +500°F) | Versatile for cryogenic to high-heat applications |

Need a reliable sealing solution for extreme conditions?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including seals, liners, and custom labware. Our expertise ensures precision production and custom fabrication—from prototypes to high-volume orders—tailored to the demanding needs of the semiconductor, medical, laboratory, and industrial sectors.

Let us help you achieve superior performance and reliability in your most challenging applications. Contact our experts today for a consultation and quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- How do PTFE expansion bellows benefit pulse dampeners? Achieve Superior Flow Stability and Corrosion Resistance

- What are the key properties of PTFE that make it suitable for impellers? Achieve Pure, Contamination-Free Mixing

- What are the compression and rebound characteristics of ePTFE gaskets? Master Sealing for Demanding Flanges

- What are the steps involved in PTFE isostatic pressing? A Guide to Uniform, Complex Parts

- Why is lubrication important in PTFE machining? Master Heat Control for Precision Parts

- What is virgin PTFE sheet and how is it different from Teflon? | Choosing the Right Grade for Your Application

- What pressure considerations apply to PTFE lined butterfly valves? Avoid Liner Failure and Ensure Safe Operation

- In which aerospace applications are PTFE spring-energized seals used? Ensuring Reliability in Extreme Environments