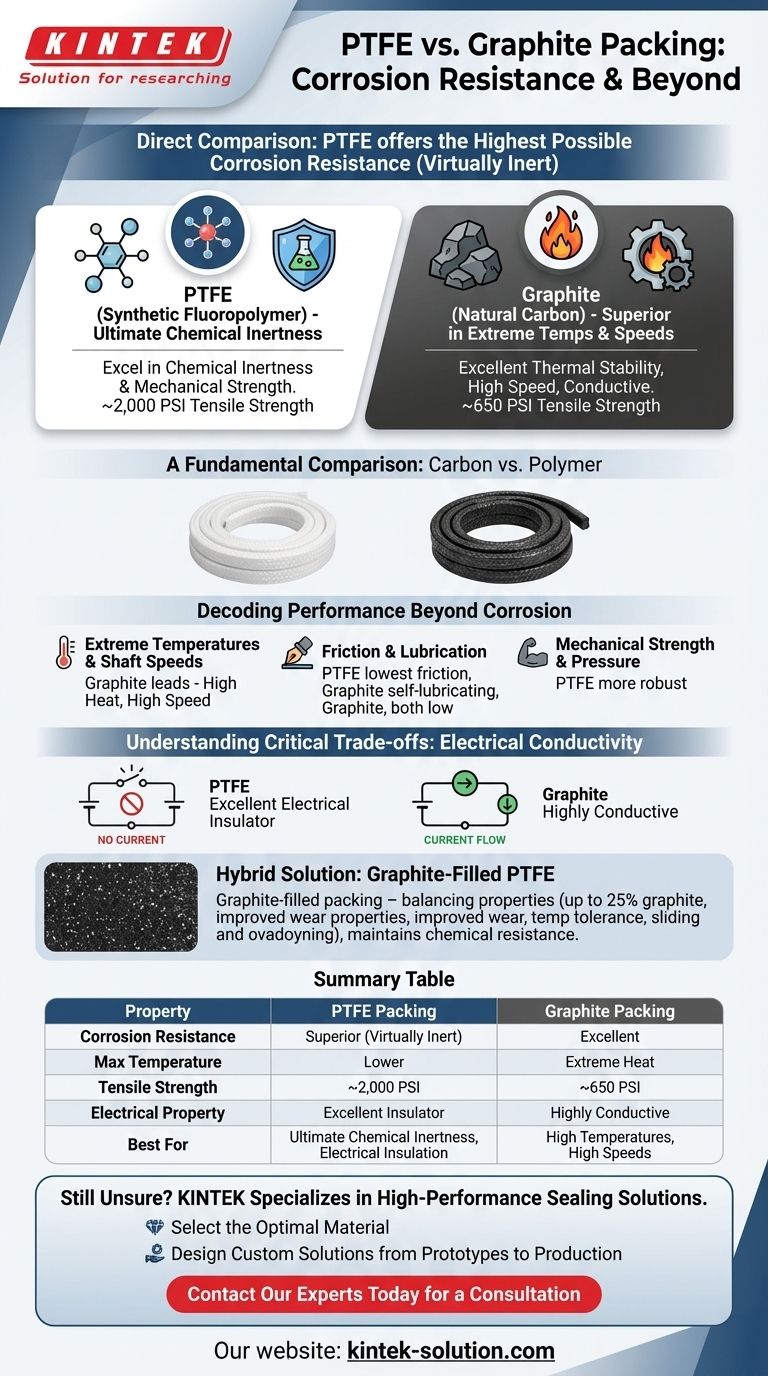

In a direct comparison, PTFE packing offers the highest possible corrosion resistance, making it virtually inert to almost all chemicals. While graphite packing also provides high corrosion resistance suitable for a vast range of applications, PTFE is the superior choice when absolute chemical inertness is the primary requirement.

The decision between PTFE and graphite packing rarely comes down to corrosion resistance alone, as both are excellent. The choice is driven by other critical operating conditions: PTFE excels in chemical inertness and mechanical strength, while graphite is superior in extreme temperatures, high speeds, and applications requiring electrical conductivity.

A Fundamental Comparison: Carbon vs. Polymer

Understanding the core nature of these two materials is the first step in selecting the right one for your needs. They come from entirely different origins, which dictates their fundamental properties.

Composition and Origin

Graphite is an inorganic, naturally occurring form of pure carbon. It is processed and braided into a packing material known for its thermal stability.

PTFE (polytetrafluoroethylene) is a synthetic fluoropolymer, a type of plastic engineered for extreme chemical resistance and low friction.

Visual and Structural Differences

Visually, the difference is stark. Graphite packing is typically black and has a braided texture.

PTFE packing is characteristically white and can be lubricated during manufacturing to create a flexible, dense packing material.

Decoding Performance Beyond Corrosion

While PTFE is the undisputed winner for pure chemical inertness, this is only one piece of the puzzle. The operational environment often places other demands on the packing material that are just as critical.

Extreme Temperatures and Shaft Speeds

Graphite is the clear leader for high-temperature services and high shaft speeds. Its natural structure allows it to withstand extreme heat and dissipate it effectively without breaking down.

PTFE has a more limited temperature range and is generally not suited for the same high-speed, high-heat applications as graphite.

Friction and Lubrication

PTFE has one of the lowest coefficients of friction of any solid material, making it incredibly slick and reducing wear on equipment shafts.

Graphite also has a low coefficient of friction and is naturally self-lubricating, allowing it to perform well in both wet and dry conditions.

Mechanical Strength and Pressure

PTFE packing has a significantly higher tensile strength, rated at approximately 2,000 PSI. This makes it more robust against extrusion and mechanical stress.

Graphite packing has a lower tensile strength, around 650 PSI, which must be considered in high-pressure environments.

Understanding the Critical Trade-offs

The choice between PTFE and graphite is a classic engineering trade-off. Excelling in one area often means a compromise in another. The most significant differentiator is often electrical conductivity.

Electrical Conductivity: A Decisive Factor

Graphite is highly conductive. This can be an advantage in applications requiring static dissipation, but it is a critical failure point if electrical insulation is needed.

PTFE is an excellent electrical insulator. This property makes it the only choice for applications where the packing must prevent electrical current from passing through.

The Hybrid Solution: Graphite-Filled PTFE

To bridge the gap, manufacturers offer graphite-filled PTFE. This composite material, which appears black, combines the strengths of both.

Adding graphite (up to 25%) to PTFE improves its wear resistance, slightly increases its temperature tolerance, and enhances its sliding properties, all while maintaining excellent chemical resistance.

Making the Right Choice for Your Application

Selecting the correct packing requires you to prioritize your application's most critical demand.

- If your primary focus is ultimate chemical inertness: Choose PTFE for its unmatched ability to withstand aggressive chemicals and caustic substances.

- If your primary focus is extreme temperature or high speed: Choose graphite for its superior thermal stability and self-lubricating performance under demanding conditions.

- If your primary focus is electrical isolation: You must use PTFE, as graphite's conductive nature is a non-starter.

- If your primary focus is a balance of wear resistance and chemical inertness: Consider graphite-filled PTFE to gain durability and thermal performance without significantly compromising chemical resistance.

Ultimately, the best material is the one whose properties align perfectly with the specific operational demands of your system.

Summary Table:

| Property | PTFE Packing | Graphite Packing |

|---|---|---|

| Corrosion Resistance | Superior (Virtually Inert) | Excellent |

| Max Temperature | Lower | Extreme Heat |

| Tensile Strength | ~2,000 PSI | ~650 PSI |

| Electrical Property | Excellent Insulator | Highly Conductive |

| Best For | Ultimate Chemical Inertness, Electrical Insulation | High Temperatures, High Speeds |

Still Unsure Which Packing Material is Right for Your Application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom seals and packing. Our expertise helps companies in the semiconductor, medical, laboratory, and industrial sectors solve complex sealing challenges.

We can help you:

- Select the optimal material (PTFE, Graphite, or a composite) based on your specific chemical, temperature, and pressure requirements.

- Design custom solutions from prototypes to high-volume production runs, ensuring precision and reliability.

Contact our experts today for a consultation to ensure your system has the right packing for peak performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the primary applications of PTFE PCBs? The Ultimate Guide for High-Frequency & Harsh Environments

- What types of fasteners and custom parts can be made from Teflon (PTFE)? Explore Its Unique Advantages

- In which industries are PTFE O-Rings commonly used? Solve Extreme Sealing Challenges

- What makes PTFE seals suitable for high-temperature and high-pressure environments? Unlock Superior Sealing Performance

- How is a PTFE bearing pad installed on prefabricated beams? A Guide to Secure, Low-Friction Installation

- Can you provide an example comparing PTFE and PTFE envelope gaskets in a practical scenario? Ensure a Reliable Seal in Demanding Applications

- What are the steps for installing PTFE seals? A Guide to Leak-Free, Long-Lasting Performance

- What are some tips for successful Teflon machining? Master Precision Cuts for PTFE Components