At its core, PTFE packing is not a single product but a family of specialized sealing materials. The different types are distinguished primarily by the materials they are blended with—such as graphite or aramid—and their physical construction, which are engineered to handle specific operational challenges like high temperatures, abrasive media, or high pressure.

The most effective PTFE packing isn't necessarily the purest; it's the one whose composition and construction are precisely matched to the temperature, pressure, speed, and chemical environment of your specific application.

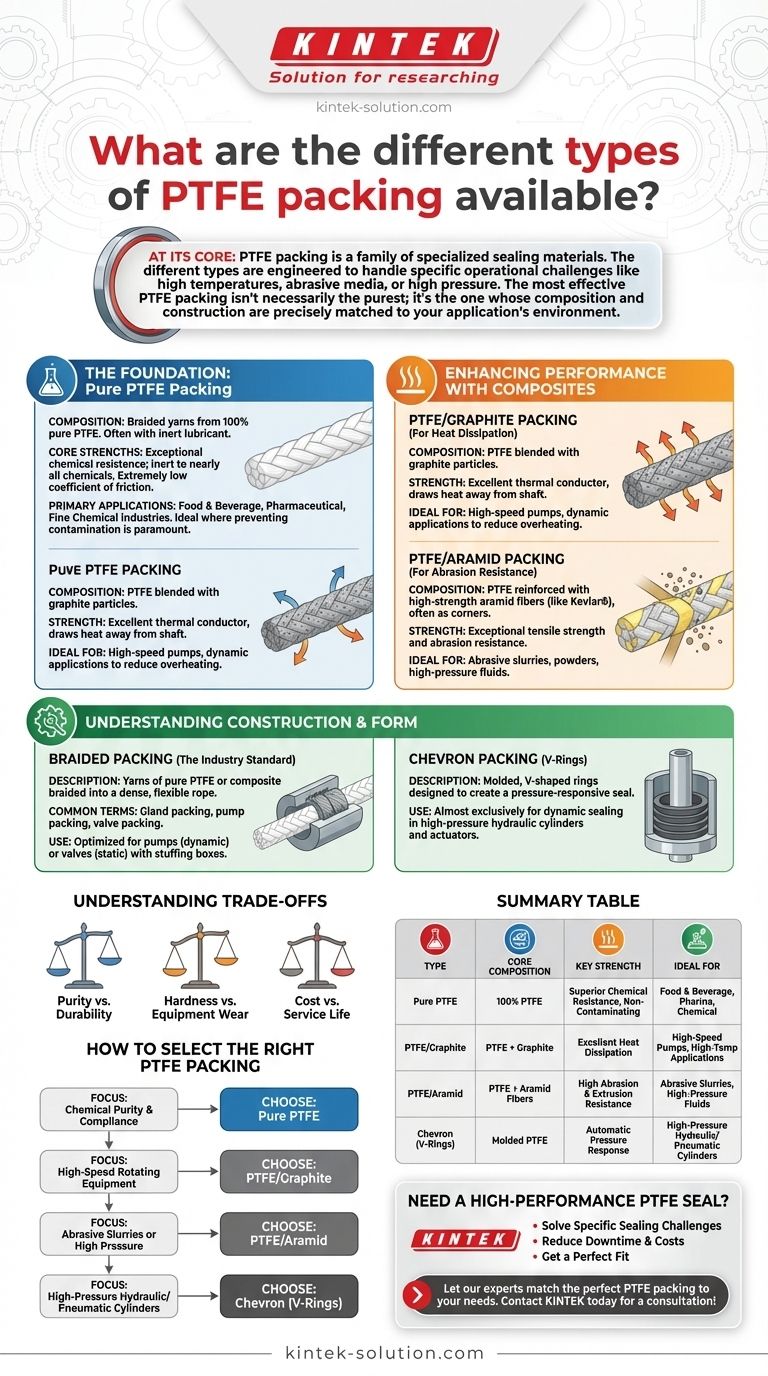

The Foundation: Pure PTFE Packing

What It Is

This is the most fundamental type of packing, created by braiding yarns made from 100% pure Polytetrafluoroethylene (PTFE). It may also be impregnated with a chemically inert lubricant to reduce friction during break-in.

Core Strengths

Pure PTFE packing is valued for its exceptional chemical resistance, making it inert to nearly all industrial chemicals and solvents. It also has an extremely low coefficient of friction, which minimizes wear on shafts and stems.

Primary Applications

Its purity and non-contaminating properties make it the standard choice for applications in the food and beverage, pharmaceutical, and fine chemical industries, where preventing product contamination is paramount.

Enhancing Performance with Composite Materials

Pure PTFE has limitations, particularly in its ability to dissipate heat and resist deformation under pressure. To overcome this, PTFE yarns are often combined with other materials to create a high-performance composite.

For Heat Dissipation: PTFE/Graphite Packing

This common composite blends PTFE with graphite particles. The graphite is an excellent thermal conductor, drawing heat away from the rotating shaft.

This significantly reduces the risk of overheating and packing failure, making it ideal for high-speed pumps and other dynamic applications where friction generates significant heat.

For Abrasion Resistance: PTFE/Aramid Packing

Aramid is a high-strength synthetic fiber (the same family as Kevlar®). When braided into the packing, often as corner reinforcements, it provides exceptional tensile strength and abrasion resistance.

This type is essential for sealing equipment that handles abrasive slurries, powders, or high-pressure fluids that would quickly destroy pure PTFE packing.

Understanding Construction and Form

Beyond material composition, the physical design of the packing is critical. Most of the terms you encounter refer to either the braiding method or the final shape of the seal.

Braided Packing (The Industry Standard)

This is the most common form, where yarns of pure PTFE or a composite are braided into a dense, flexible rope. This form factor is what is typically meant by "gland packing," "pump packing," or "valve packing."

The specific density and lubricant used may be optimized for a pump (dynamic sealing) versus a valve (static sealing), but the underlying construction is the same.

Chevron Packing (V-Rings)

This is not a braided packing. Chevron packing consists of a set of molded, V-shaped rings made from PTFE or other materials.

These rings are designed to create a seal that automatically responds to pressure changes. They are used almost exclusively for dynamic sealing in high-pressure hydraulic cylinders and actuators, not in standard pumps or valves with stuffing boxes.

Understanding the Trade-offs

Selecting the right packing involves balancing performance characteristics. An enhancement in one area often means a compromise in another.

Purity vs. Durability

While pure PTFE offers maximum chemical resistance and purity, it is mechanically weak. Adding graphite or aramid dramatically increases temperature and pressure ratings but may not be suitable for applications where trace contamination is unacceptable.

Hardness vs. Equipment Wear

Aramid-reinforced packing is extremely durable, but its hardness can cause increased wear on softer shafts. It is crucial to ensure the shaft material is sufficiently hardened or that the packing is correctly installed and not over-tightened to prevent premature equipment damage.

Cost vs. Service Life

High-performance composite packings are more expensive upfront. However, their extended service life in demanding applications reduces equipment downtime and labor costs, resulting in a lower total cost of ownership.

How to Select the Right PTFE Packing

Your selection should be guided by the primary demand of your application.

- If your primary focus is chemical purity and compliance: Choose a packing made from 100% pure, virgin PTFE yarns, often with a food-grade lubricant.

- If you are sealing high-speed rotating equipment like pumps: Select a PTFE/graphite composite packing to effectively manage heat buildup and prevent failure.

- If your application involves abrasive slurries or high pressures: Use a PTFE packing reinforced with aramid fibers for maximum durability and extrusion resistance.

- If you are servicing high-pressure hydraulic or pneumatic cylinders: Look specifically for Chevron (V-ring) packing, as its design is purpose-built for that dynamic sealing function.

Matching the packing's engineering to your specific operational challenge is the key to achieving a reliable, long-lasting seal.

Summary Table:

| Packing Type | Core Composition | Key Strength | Ideal For |

|---|---|---|---|

| Pure PTFE | 100% PTFE | Superior Chemical Resistance, Non-Contaminating | Food & Beverage, Pharmaceutical, Chemical Processing |

| PTFE/Graphite | PTFE + Graphite | Excellent Heat Dissipation | High-Speed Pumps, High-Temperature Applications |

| PTFE/Aramid | PTFE + Aramid Fibers | High Abrasion & Extrusion Resistance | Abrasive Slurries, High-Pressure Fluids |

| Chevron (V-Rings) | Molded PTFE | Automatic Pressure Response | High-Pressure Hydraulic/Pneumatic Cylinders |

Need a High-Performance PTFE Seal?

KINTEK specializes in manufacturing precision PTFE components, including custom packing seals, for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

We can help you:

- Solve Specific Sealing Challenges with materials engineered for your exact temperature, pressure, and chemical environment.

- Reduce Downtime & Costs with durable, long-lasting seals that offer a lower total cost of ownership.

- Get a Perfect Fit with custom fabrication services, from rapid prototypes to high-volume production runs.

Let our experts match the perfect PTFE packing to your needs. Contact KINTENG today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications